Si-based AlGaN/GaN HEMT based on wrapping buried layer and diffusion barrier layer and preparation method

A barrier layer and wrapping technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of lower substrate resistivity, increased radio frequency loss, and large radio frequency loss, so as to reduce P-type conductive doping, Effect of reducing radio frequency loss and increasing resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

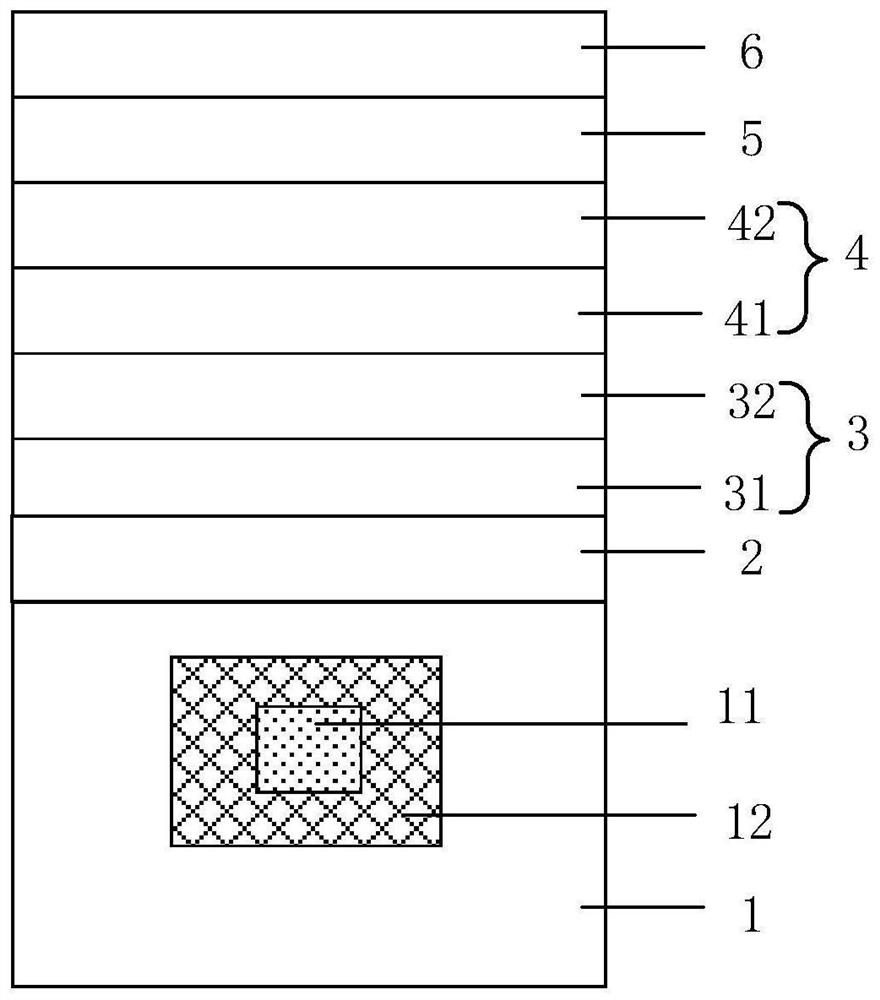

[0031] See figure 1 , figure 1 A schematic structural diagram of a Si-based AlGaN / GaN HEMT based on a buried layer and a diffusion barrier layer provided by an embodiment of the present invention.

[0032] The Si-based AlGaN / GaN HEMT includes a Si substrate 1, a diffusion barrier layer 2, an AlN nucleation layer 3, an AlGaN step change layer 4, a GaN buffer layer 5 and an AlGaN barrier layer 6 stacked in sequence, wherein the Si substrate 1 An N-type buried layer 11 and an isolation layer 12 are disposed in the Si substrate 1, and the isolation layer 12 is disposed between the Si substrate 1 and the N-type buried layer 11 and wraps the N-type buried layer.

[0033] In this embodiment, both the N-type buried layer 11 and the isolation layer 12 are disposed in the Si substrate 1, that is, the isolation layer 12 is wrapped around the N-type buried layer 11, and the Si substrate 1 is wrapped around the isolation layer 12. , the setting of the isolation layer 12 meets the followi...

Embodiment 2

[0054] On the basis of Example 1, please refer to Figure 3a-Figure 3g , Figure 3a-Figure 3g A process schematic diagram of a method for preparing a Si-based AlGaN / GaN HEMT based on a buried layer and a diffusion barrier layer provided by an embodiment of the present invention. The method includes steps:

[0055] S1, prepare the first isolation sublayer 121 in the Si sheet 13, please refer to Figure 3a and Figure 3b .

[0056] First, put the Si sheet 13 into 20% HF acid solution and soak it for 60s, and then soak it with H 2 o 2 , alcohol and acetone, and finally rinse with flowing deionized water for 60s.

[0057] Then, put the cleaned substrate into a low-pressure MOCVD reaction chamber, inject hydrogen gas, raise the temperature to 1000° C., control the pressure of the reaction chamber to 40 Torr, and heat-treat the substrate in a hydrogen atmosphere for 3 minutes.

[0058] Then, after the thermal cleaning stage is over, the temperature of the reaction chamber is l...

Embodiment 3

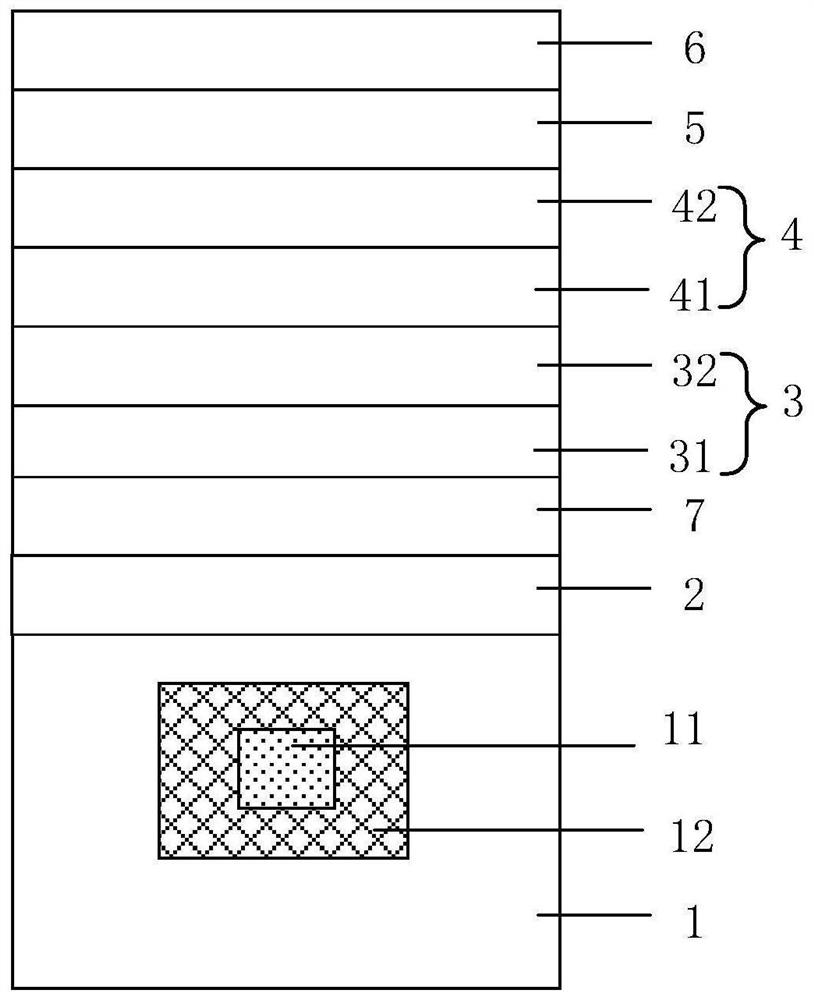

[0094] On the basis of Example 2, please combine figure 2 , the embodiment of the present invention provides another method for preparing a Si-based AlGaN / GaN HEMT based on a buried layer and a diffusion barrier layer. The preparation method includes the steps of:

[0095] S1 , preparing the first isolation sublayer 121 in the Si sheet 13 .

[0096] S2 , performing ion implantation on the surface layer of the first isolation sublayer 121 to form the N-type buried layer 11 .

[0097] S3 , growing the second isolation sublayer 122 on the first isolation sublayer 121 and the N-type buried layer 11 to form the isolation layer 12 .

[0098] S4 , growing single crystal silicon 14 on the Si sheet 13 and the second isolation sublayer 122 to form the Si substrate 1 .

[0099] S5 , preparing a diffusion barrier layer 2 on the Si substrate 1 .

[0100] S6 , preparing a pre-coated aluminum layer 2 on the diffusion barrier layer 2 .

[0101] Specifically, the temperature of the reacti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com