Quick wiring construction method for multi-core control cable

A technology for controlling cables and construction methods, applied in the directions of circuits, connections, electrical components, etc., can solve the problems that it is difficult for engineers and technicians to check the correctness of wiring, and the rules and errors of hierarchical identification are wrong.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

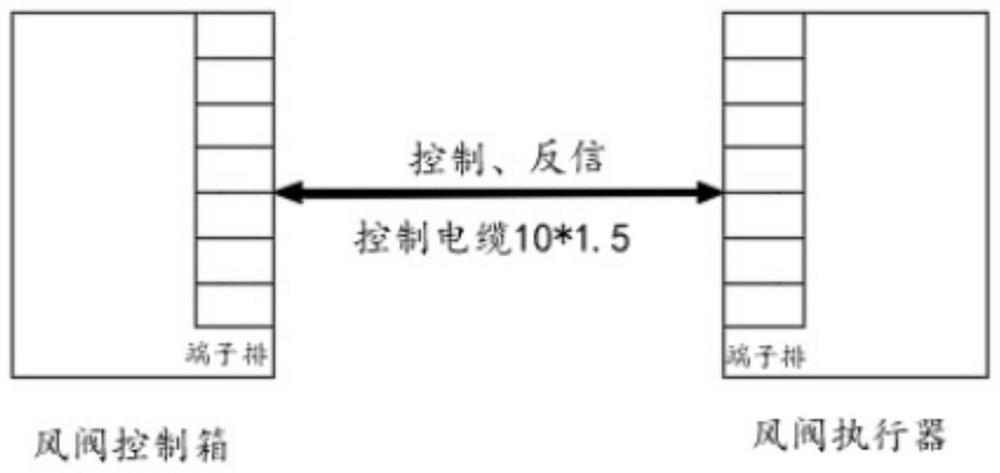

[0029] like figure 1 , figure 2 , image 3 As shown, the multi-core control cable quick connection construction method of the present invention includes:

[0030] Match the equipment that needs to be connected to the control cable; further match the terminal function and terminal number of the matched equipment to form a wiring scheme for the control cable core;

[0031] According to the matching result, determine the number of cores of the control cable to be connected;

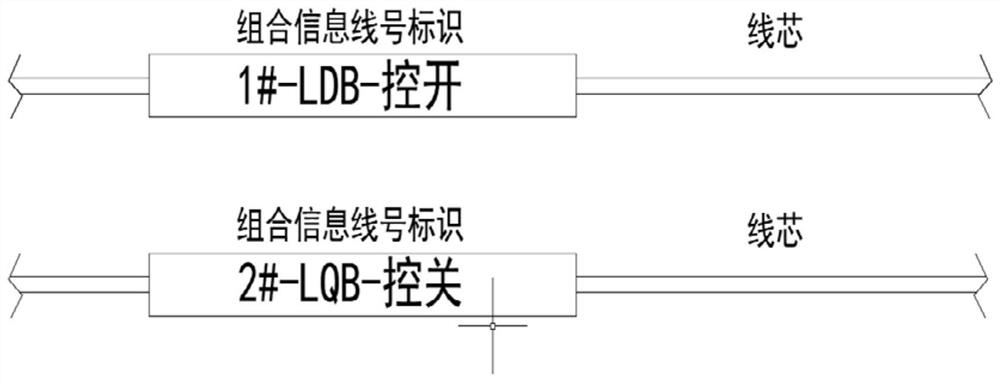

[0032] Set each wire core of the control cable connected to the equipment to a unique color, so that after the control cable is connected, the terminal number, terminal function, and wire core color of the equipment match and correspond.

[0033] In the multi-core control cable quick connection construction method of the present invention, setting each core of the control cable connected to the equipment as a unique color includes: setting each core of the control cable connected to the equipment as a un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com