Steel heat treatment deformation treatment method

A technology of heat treatment deformation and treatment method, applied in the field of heat treatment of metal materials, can solve the problems of high hardness, high yield strength, and easy cracks in correction, and achieve the effects of small cooling rate, small deformation, and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

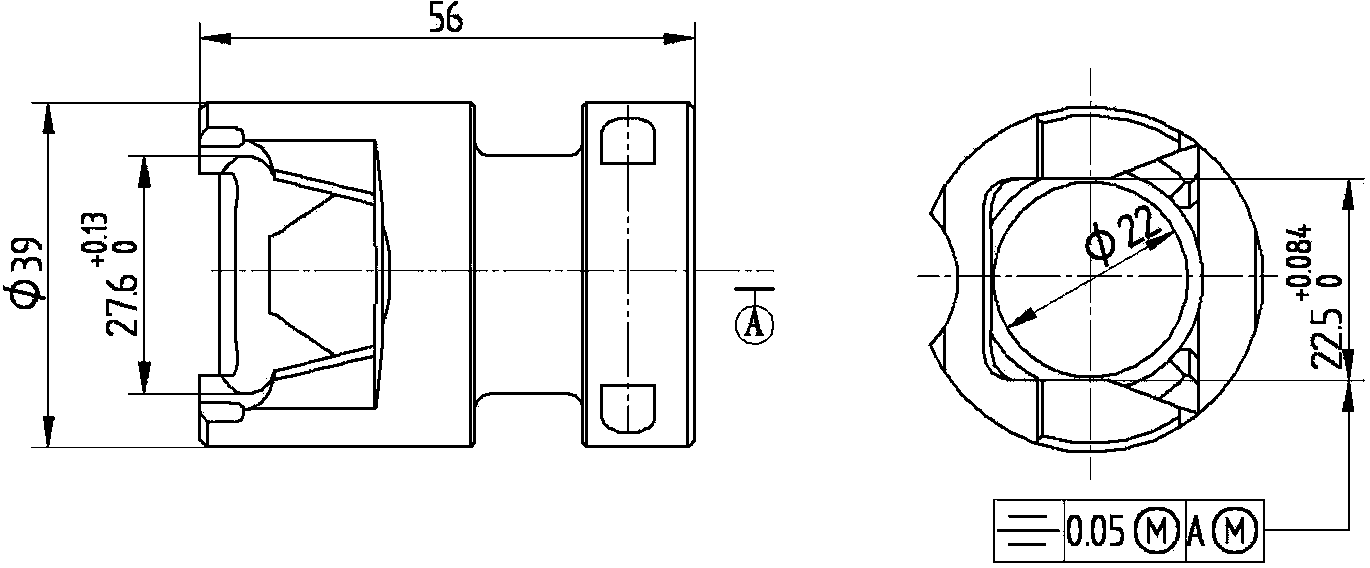

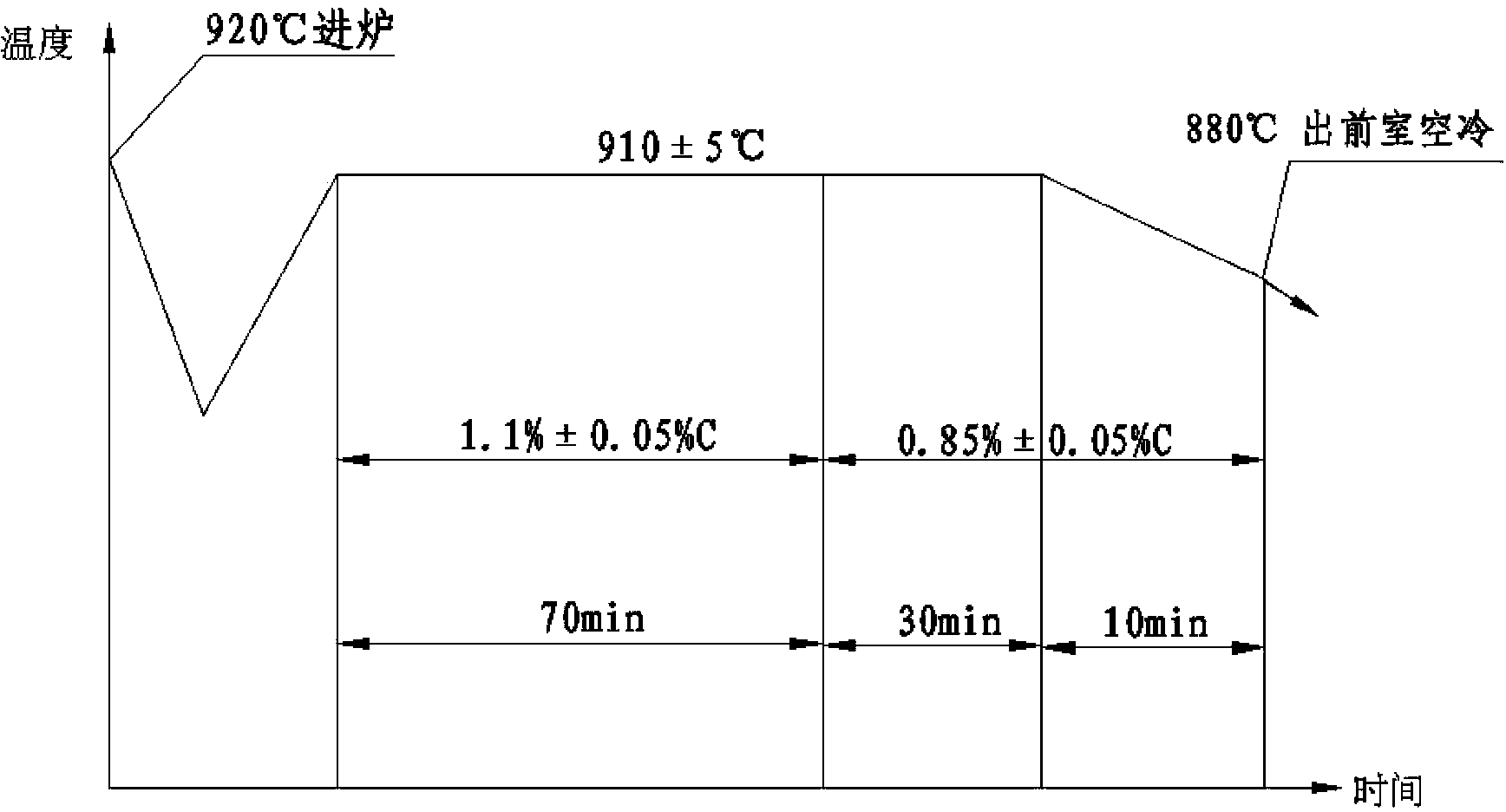

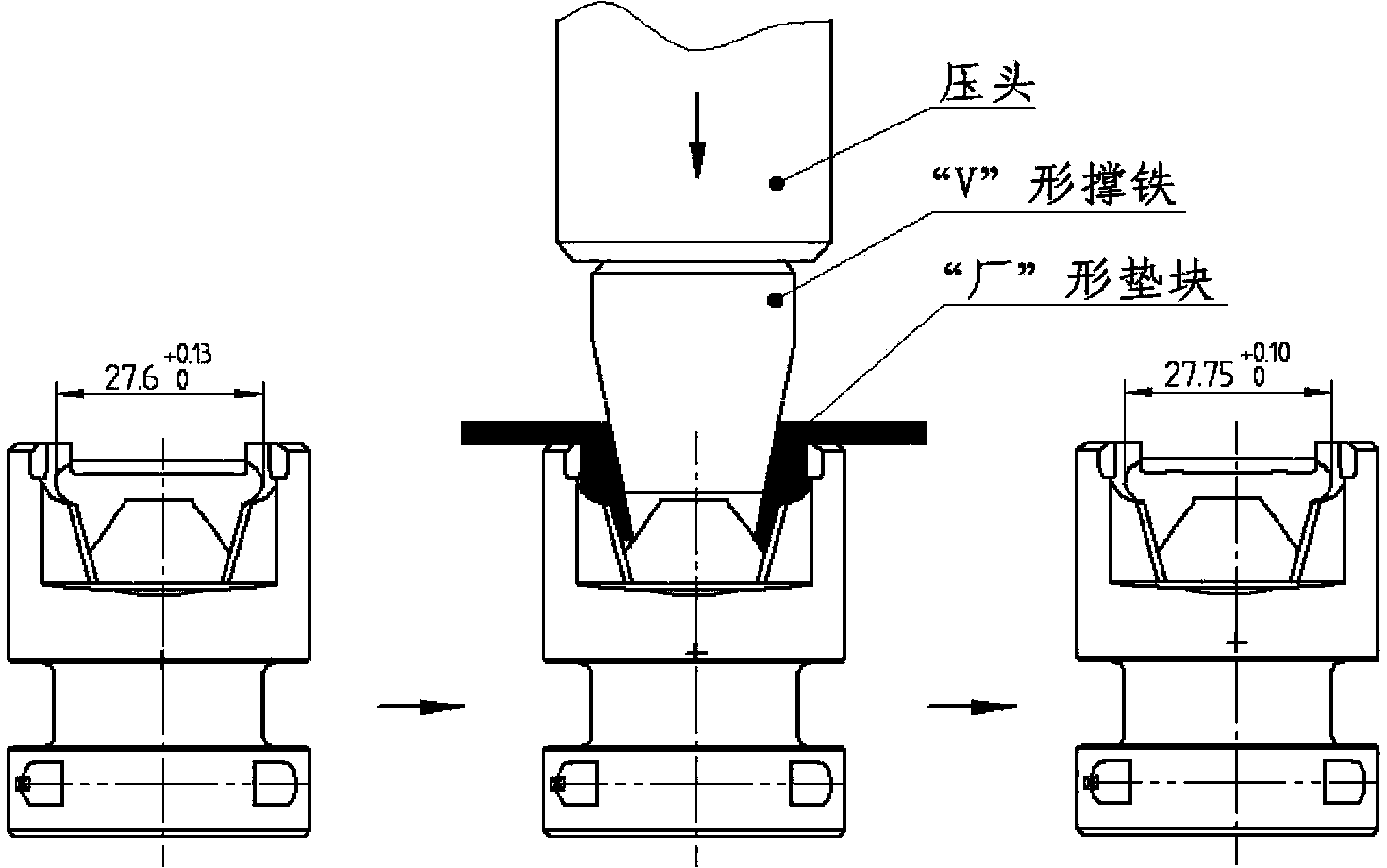

[0039] Attached below Figures 1 to 4 Specific embodiments of the present invention are described in detail.

[0040] In an embodiment of the present invention, taking a joint sleeve of a firearm part as an example, a steel heat treatment deformation treatment method of the present invention is applied to the heat treatment process of the joint sleeve for illustration.

[0041] It should be noted that although the present invention is described here by applying a steel heat treatment and deformation treatment method according to the present invention to the heat treatment process of a typical component joint made of 25Cr2Ni4WA steel, those skilled in the art can understand Yes, the present invention is not limited thereto. Rather, the present invention can also be applied to the heat treatment process of other parts made of 25Cr2Ni4WA steel (for example, firing pin, hammer, joint sleeve, bolt, bolt frame, machine head, shell hook, ejector rod, etc.) middle.

[0042] The kno...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com