Self-leveling mortar and preparation method thereof

A self-leveling mortar and water-reducing agent technology, applied in the field of building materials, can solve the problems of hindered popularization and application, high application cost, and slow development, and achieve the effects of improving overall performance, improving decoration quality, and saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

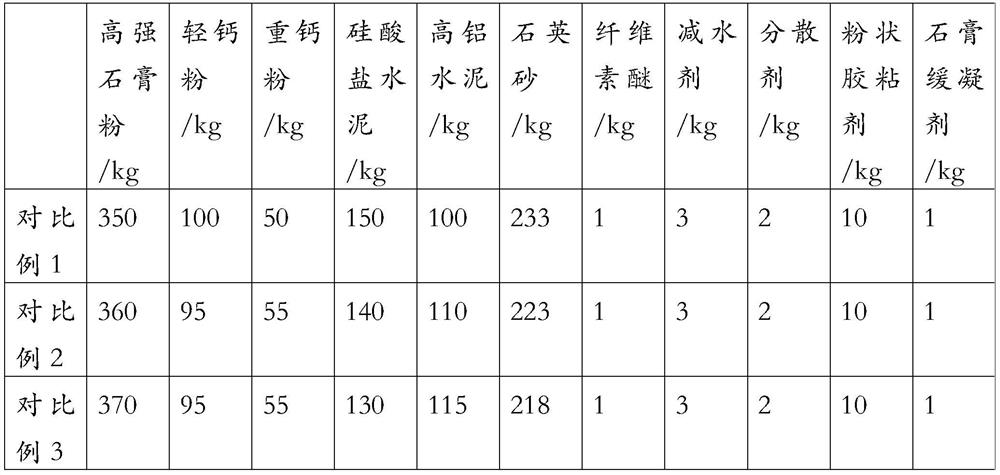

[0024] A preparation method of self-leveling mortar, comprising:

[0025] Step 1. Add high-strength gypsum powder, light calcium powder, heavy calcium powder, Portland cement, high alumina cement, and quartz sand into the gravity-free powder mixer in sequence, and stir for 10 minutes;

[0026] Step 2: Add cellulose ether, water reducer, dispersant, powdery adhesive, and gypsum retarder in sequence, and continue to stir for 30 minutes until evenly stirred.

[0027] The stirring speed is 200-300r / min.

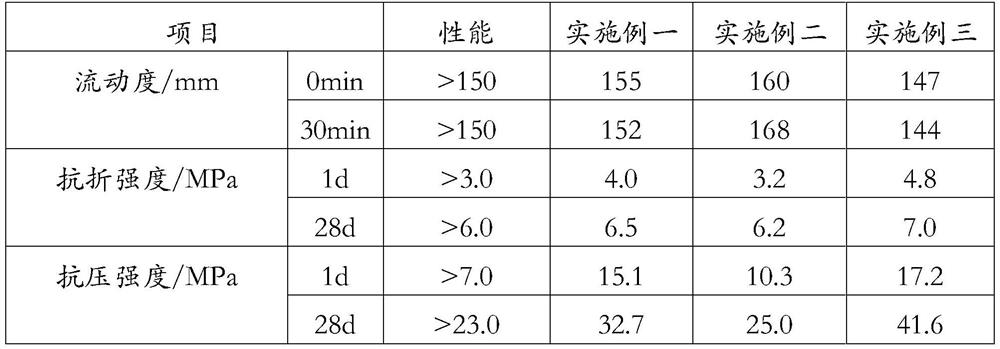

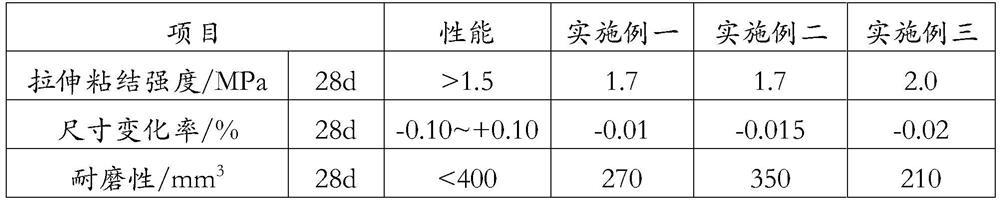

Embodiment 1

[0029] A self-leveling mortar, using 450kg of high-strength gypsum powder, 100kg of light calcium powder, 50kg of heavy calcium powder, 100kg of Portland cement, 50kg of high alumina cement, 233kg of quartz sand, 1kg of cellulose ether, 3kg of water reducing agent, and 2kg of dispersant , powdered adhesive 10kg, gypsum retarder 1kg.

[0030] A preparation method of self-leveling mortar, comprising:

[0031] Step 1. Add high-strength gypsum powder, light calcium powder, heavy calcium powder, Portland cement, high alumina cement, and quartz sand into the gravity-free powder mixer in sequence, and stir for 10 minutes;

[0032] Step 2: Add cellulose ether, water reducer, dispersant, powdery adhesive, and gypsum retarder in sequence, and continue to stir for 30 minutes until evenly stirred.

[0033] The stirring speed is 250r / min.

Embodiment 2

[0035] A self-leveling mortar, using 420kg of high-strength gypsum powder, 120kg of light calcium powder, 60kg of heavy calcium powder, 100kg of Portland cement, 60kg of high alumina cement, 223kg of quartz sand, 1kg of cellulose ether, 2.5kg of water reducing agent, and dispersant 2.5kg, powdered adhesive 10kg, gypsum retarder 1kg.

[0036] A preparation method of self-leveling mortar, comprising:

[0037] Step 1. Add high-strength gypsum powder, light calcium powder, heavy calcium powder, Portland cement, high alumina cement, and quartz sand into the gravity-free powder mixer in sequence, and stir for 15 minutes;

[0038] Step 2: Add cellulose ether, water reducer, dispersant, powdery adhesive, and gypsum retarder in sequence, and continue stirring for 35 minutes until the mixture is uniform.

[0039] The stirring speed is 260r / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com