Secondary battery and terminal

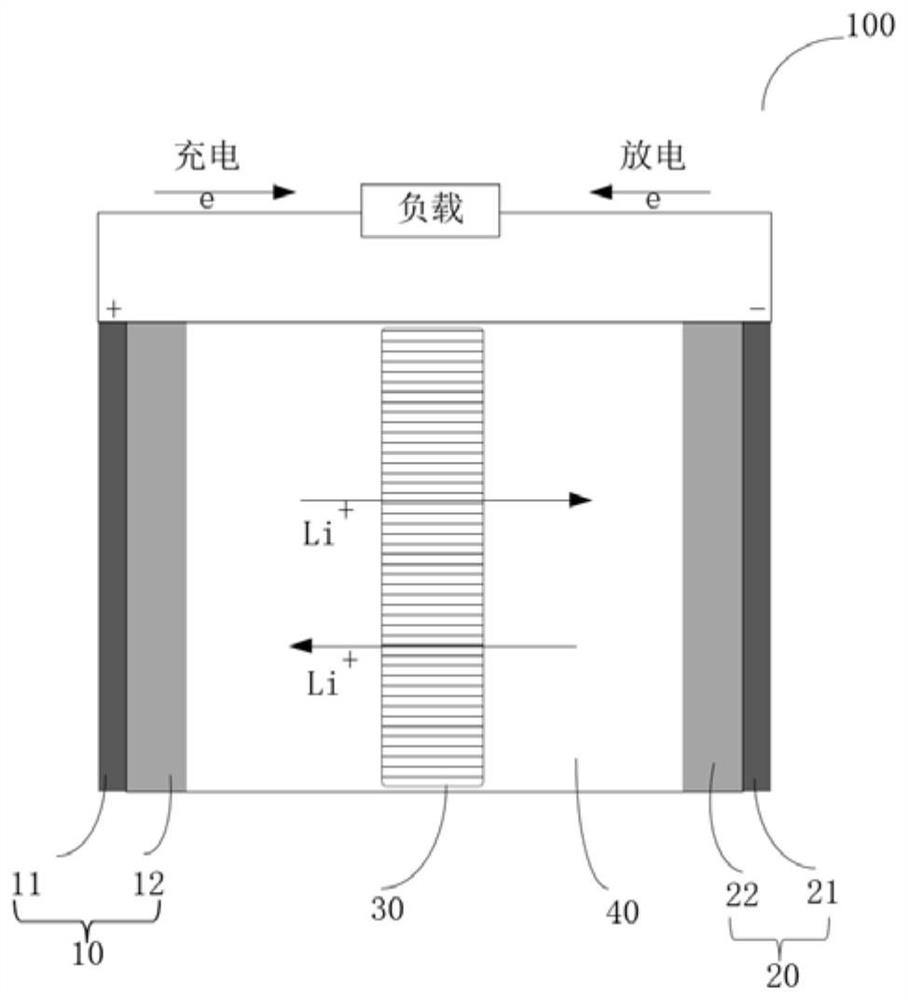

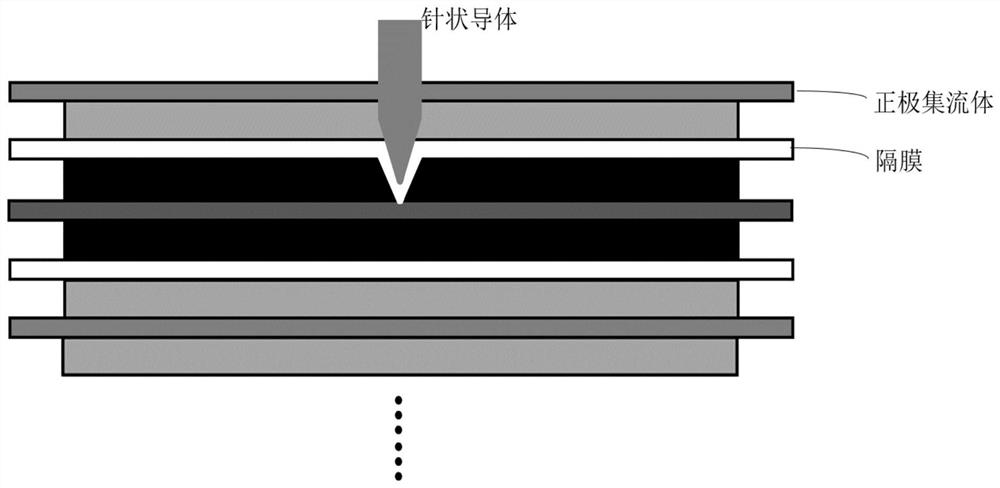

A secondary battery and terminal technology, applied in secondary batteries, secondary battery repair/maintenance, battery electrodes, etc., can solve the problems of high risk of battery thermal runaway, thermal runaway chain reaction, shrinkage and melting of diaphragm, etc., to reduce contact The probability of short circuit occurrence, the effect of alleviating the chain reaction of thermal runaway, and improving safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Lithium cobaltate is used as the positive electrode active material, aluminum foil is used as the positive electrode current collector, and the positive electrode active material layer is uniformly coated on the surface of the positive electrode current collector. The composition of the positive electrode active material layer is 97.0wt% lithium cobaltate, 1.6wt% polyvinylidene fluoride and 1.4wt% conductive carbon black, dried at 80°C, after cold pressing, cutting, slitting, and vacuum drying, the positive electrode sheet was obtained;

[0048] Graphite is used as the negative electrode active material, copper foil is used as the negative electrode current collector, and the negative electrode active material layer is evenly coated on the surface of the negative electrode current collector. The composition of the negative electrode active material layer is 97.4wt% graphite, 1.4wt% styrene-butadiene rubber and 1.2wt% Sodium methyl cellulose, dried at 80°C, cold-pressed, ...

Embodiment 2-19

[0051] The preparation method of the secondary battery is the same as in Example 1, except that the elongation of the separator, the ratio of the elongation of the separator to the thickness of the active material layer, and the ratio of the elongation of the separator to the elongation of the current collector are different from that of Example 1, specifically See Table 1.

Embodiment 20

[0059] The preparation method is the same as in Example 1, except that the thickness of the positive electrode active material layer in Example 20 is 36 μm, the thickness of the negative electrode active material layer is 48 μm, and the ratio of the elongation of the separator to the thickness of the active material layer is 5.0% / μm and 3.75% / μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com