Bamboo product protective film and preparation method thereof

A technology for bamboo products and protective films, applied in coatings, reflective/signal coatings, and biocide-containing paints, etc., can solve the problems of easy aging, inability to effectively protect the integrity of bamboo products, and general corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

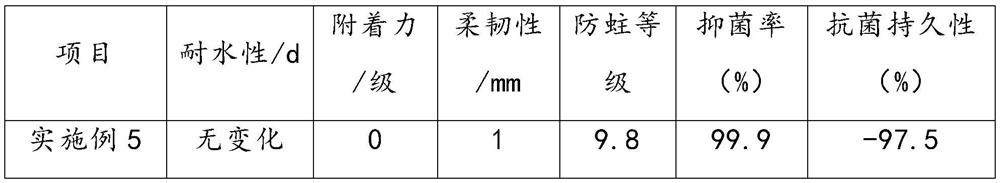

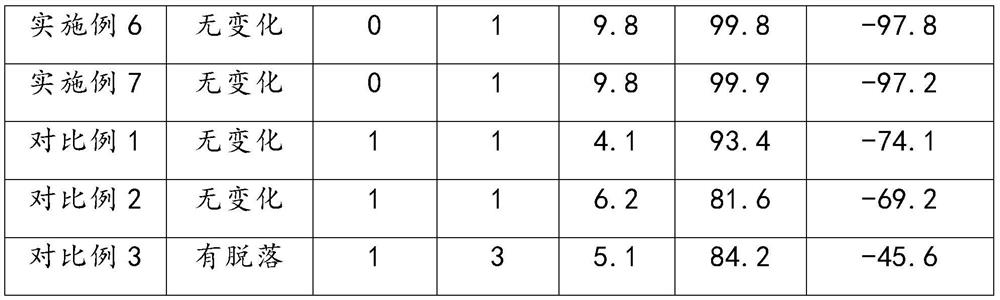

Examples

Embodiment 1

[0028] Insect repellent microcapsules are made by the following steps:

[0029] Step A1. Add dried chili powder into an ethanol solution with a mass fraction of 95% according to the ratio of material to liquid: 1g: 20mL, heat up to 55°C, perform ultrasonic extraction at a frequency of 50kHz for 45min, then centrifuge for 15min, filter under reduced pressure, and spin evaporate the filtrate to remove ethanol solution to obtain capsaicin;

[0030] Step A2. Add 20g of dried mugwort leaves to 400mL of deionized water, then adjust the pH value to 4.0 with citric acid, soak for 24 hours, ultrasonically extract at 200W for 30 minutes, heat in a water bath at 80°C for 2 hours, filter with gauze while it is hot, and pump the filtrate again Filtrate the supernatant, vacuum freeze-dry to obtain Artemisia argyi extract;

[0031] Step A3: Add 1g of gelatin to 10mL of deionized water at 75°C to obtain a gelatin solution, add 0.2g of capsaicin and 0.3g of Artemisia argyi leaf extract to 2.8...

Embodiment 2

[0034] Antibacterial particles are made by the following steps:

[0035] Step S1, at room temperature, add 65.4 mg of cetyltrimethylammonium bromide into 200 mL of deionized water, stir magnetically for 5 min, add 5 mL of sodium borohydride solution with a concentration of 0.05 mol / L, and stir for 20 min at a speed of 60 r / min Finally, add 2.1 mL of silver nitrate solution with a concentration of 0.1 mol / L dropwise, and control the rate of addition to 1 drop / second. After the addition, continue the reaction for 10 minutes to obtain nano-silver colloids. Add 50 mL of absolute ethanol to the nano-silver colloids. Adjust the pH value to 4 with glacial acetic acid, then add 0.32mL tetrabutyl titanate, stir at 100r / min for 2h, then centrifuge at 3000r / min for 15min, wash the precipitate with deionized water 3 times, and finally dry it in an oven at 25°C for 20min , calcined at 500°C for 1 h, cooled to obtain hybrid particles;

[0036] Step S2, ultrasonically disperse 0.3g of hybri...

Embodiment 3

[0038] Insect repellent microcapsules are made by the following steps:

[0039] Step A1. Add dried chili powder into an ethanol solution with a mass fraction of 95% according to the ratio of material to liquid: 1g: 20mL, heat up to 55°C, perform ultrasonic extraction at a frequency of 55kHz for 60min, then centrifuge for 15min, filter under reduced pressure, and remove the ethanol by rotary evaporation of the filtrate solution to obtain capsaicin;

[0040] Step A2. Add 20g of dried mugwort leaves to 600mL of deionized water, then adjust the pH value to 4.0 with citric acid, soak for 24 hours, ultrasonically extract with a power of 200W for 30 minutes, heat in a water bath at 80°C for 2 hours, filter with gauze while it is hot, and pump the filtrate again Filtrate the supernatant, vacuum freeze-dry to obtain Artemisia argyi extract;

[0041] Step A3: Add 1 g of gelatin to 10 mL of deionized water at 80°C to obtain a gelatin solution, add gum arabic to deionized water to obtain a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com