Long-life organic light-emitting diode and preparation method and device thereof

A light-emitting diode, long-life technology, used in semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc., can solve the problems of short life, rapid brightness decay, etc., to improve work stability, wide exciton distribution range , the effect of suppressing annihilation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

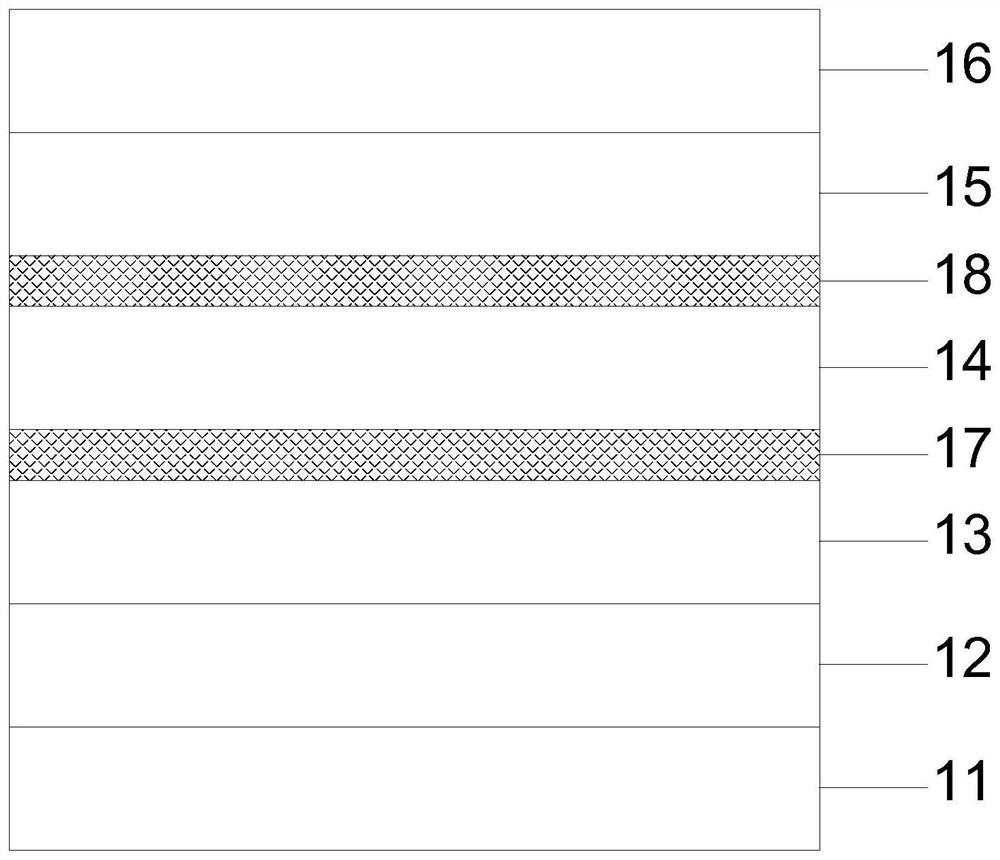

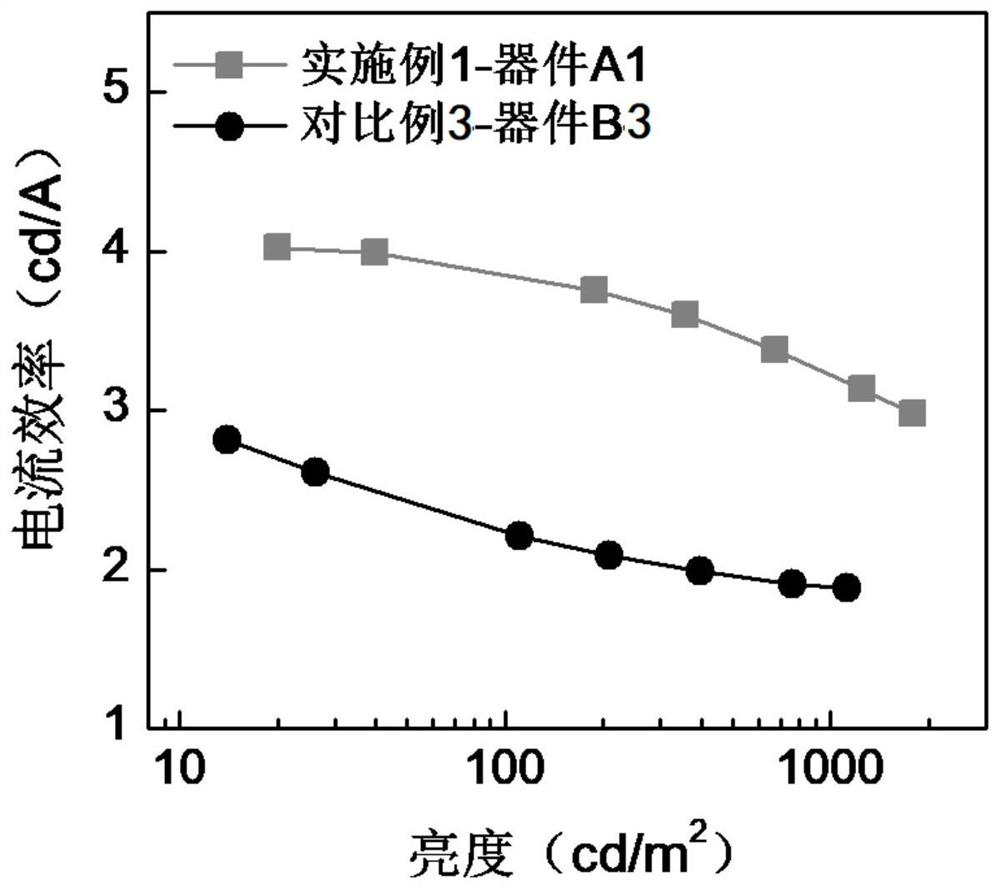

[0054] Embodiment 1: A long-life organic light-emitting diode, using a buffer layer structure with gradient concentration mixed on both sides of the light-emitting layer, using the blue light host material BH1 as the light-emitting material to prepare an organic light-emitting diode (device A1), the device structure is: ITO / HAT-CN(10nm) / HTL1(50nm) / HTL1:BH1(gradient ratio, 1:1in volume,15nm) / BH1(20nm) / ETL1:BH1(gradient ratio,1:1in volume, 15nm) / ETL1(40nm ) / Liq(2nm) / Al(100nm).

[0055] A method for preparing a long-life organic light-emitting diode. The preparation steps of the method are as follows:

[0056] Step 1: Put the ITO substrate into containers containing solvents such as detergent, acetone, isopropanol, and deionized water in sequence for ultrasonic cleaning. Each solvent is ultrasonically cleaned for 15 minutes, then blown dry with nitrogen, and use Ozone treatment for 15 minutes. Thereafter put it into a vacuum below 7.0×10 -4 In the cavity of Pa.

[0057] The ...

Embodiment 2

[0064] Embodiment 2: A long-life organic light-emitting diode, using a buffer layer structure with gradient concentration mixed on both sides of the light-emitting layer, using the blue light host material BH1 as the light-emitting material to prepare an organic light-emitting diode (device A1), the device structure is: ITO / HAT-CN(5nm) / HTL1(30nm) / HTL1:BH1(gradient ratio, 1:1in volume,10nm) / BH1(30nm) / ETL1:BH1(gradient ratio,1:1in volume, 10nm) / ETL1(55nm ) / Liq(3nm) / Al(150nm).

[0065] A method for preparing a long-life organic light-emitting diode. The preparation steps of the method are as follows:

[0066] Step 1: Put the ITO substrate into containers containing solvents such as detergent, acetone, isopropanol, and deionized water in sequence for ultrasonic cleaning. Each solvent is ultrasonically cleaned for 15 minutes, then blown dry with nitrogen, and use Ozone treatment for 15 minutes. Thereafter put it into a vacuum below 7.0×10 -4 In the cavity of Pa.

[0067] The s...

Embodiment 3

[0074] Embodiment 3: A long-life organic light-emitting diode, using a buffer layer structure with gradient concentration mixed on both sides of the light-emitting layer, using the blue light host material BH1 as the light-emitting material to prepare an organic light-emitting diode (device A1), the device structure is: ITO / HAT-CN(8nm) / HTL1(70nm) / HTL1:BH1(gradient ratio, 1:1in volume,20nm) / BH1(15nm) / ETL1:BH1(gradient ratio,1:1in volume, 20nm) / ETL1(35nm ) / Liq(4nm) / Al(80nm).

[0075] A method for preparing a long-life organic light-emitting diode. The preparation steps of the method are as follows:

[0076] Step 1: Put the ITO substrate into containers containing solvents such as detergent, acetone, isopropanol, and deionized water in sequence for ultrasonic cleaning. Each solvent is ultrasonically cleaned for 15 minutes, then blown dry with nitrogen, and use Ozone treatment for 15 minutes. Thereafter put it into a vacuum below 7.0×10 -4 In the cavity of Pa.

[0077] The se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com