Method for preparing nitrogen and potassium-containing super absorbent resin from carboxymethyl sorghum cellulose

A technology of superabsorbent resin and cellulose, which is applied in the field of high water absorption of nitrogen-containing potassium, can solve the problems of high reaction temperature and low water absorption, and achieve the effects of simple synthesis process, increased water permeability and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

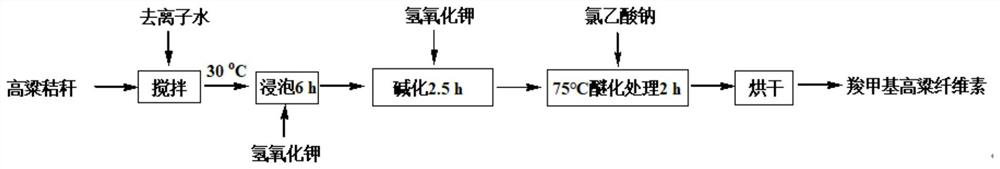

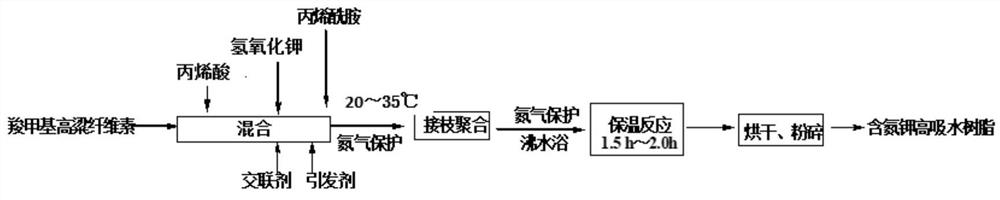

Method used

Image

Examples

Embodiment 1

[0050] Weigh 12.43g of potassium hydroxide, measure 32.0mL of deionized water, prepare potassium hydroxide solution, and neutralize 20g (18.87mL) of acrylic acid under the conditions of cooling and stirring in an ice-water bath to prepare acrylic acid and its potassium salt solution , where the degree of neutralization of acrylic acid is 80%. Weigh 5.0g carboxymethyl sorghum cellulose, 5.0g acrylamide, 100mg ammonium persulfate, 75mg sodium bisulfite, 50.0mg N,N'-methylene bisacrylamide, measure 70.0mL deionized water, all Add it into the reactor, and pour the prepared acrylic acid and its potassium salt solution into the reactor, and stir at room temperature for 2 hours to make it evenly mixed. Stir and heat under the protection of nitrogen, and control the heating rate at the same time to increase the temperature of the water bath slowly. When the temperature rises to 25-35°C, stop stirring, and then gradually increase the temperature. It reacted in this temperature range f...

Embodiment 2

[0053] Weigh 10.88g of potassium hydroxide, measure 22.0mL of deionized water, prepare potassium hydroxide solution, and neutralize 20g (18.87mL) of acrylic acid under the conditions of cooling and stirring in an ice-water bath to prepare acrylic acid and its potassium salt solution , where the degree of neutralization of acrylic acid is 70%. Weigh 2.7g carboxymethyl sorghum cellulose, 4.0g acrylamide, 250mg ammonium persulfate, 187.5mg sodium bisulfite, 100.0mg N,N'-methylenebisacrylamide, measure 70.0mL deionized water, All were added into the reactor, and the prepared acrylic acid and its potassium salt solution were poured into the reactor, and stirred at room temperature for 2 hours to make it evenly mixed. Stir and heat under the protection of nitrogen, and control the heating rate at the same time to increase the temperature of the water bath slowly. When the temperature rises to 25-35°C, stop stirring, and then gradually increase the temperature. It reacted in this te...

Embodiment 3

[0056] Weigh 9.33g of potassium hydroxide, measure 26.0mL of deionized water, prepare potassium hydroxide solution, and neutralize 20g (18.87mL) of acrylic acid under the conditions of cooling and stirring in an ice-water bath to prepare acrylic acid and its potassium salt solution , where the degree of neutralization of acrylic acid is 60%. Weigh 3.9g carboxymethyl sorghum cellulose, 3.3g acrylamide, 200mg ammonium persulfate, 150mg sodium bisulfite, 60.0mg N,N'-methylene bisacrylamide, measure 70.0mL deionized water, all Add it into the reactor, and pour the prepared acrylic acid and its potassium salt solution into the reactor, and stir at room temperature for 2 hours to make it evenly mixed. Stir and heat under the protection of nitrogen, and control the heating rate at the same time to increase the temperature of the water bath slowly. When the temperature rises to 25-35°C, stop stirring, and then gradually increase the temperature. It reacted in this temperature range f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com