A kind of flexible graphite impregnant formulation and its preparation and application process

A technology of flexible graphite and impregnating agent, applied in the field of impregnating agent of carbon or graphite materials, can solve the problems of unsatisfactory effect of anode carbon block transformation, increasing the number of carbon anode roasting, high cost, etc., so as to reduce ineffective waste. The effect of reducing slag rate, increasing anode compactness and reducing slag removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The high-efficiency flexible graphite impregnating agent in this embodiment is a glue solution prepared by mixing 15% flexible graphite, a total amount of 5% treatment agent and 85% water;

[0031] Flexible graphite is a mixture of various expandable graphites, and the flexible graphite meets the following requirements at the same time:

[0032] 1. The expandable graphite whose expansion temperature is between 60℃-100℃ accounts for 5%, the expandable graphite whose expansion temperature is between 100℃-300℃ accounts for 5%, and the expandable graphite whose expansion temperature is above 300℃ accounts for 5%. %.

[0033] In this embodiment, the treating agent is composed of an oxidizing agent, a coupling agent, a dispersing agent, and a thickening agent. Aminopropyltriethoxysilane, dispersant is 1% sodium lignosulfonate, thickener is 1% potassium chloride.

[0034] The concrete steps of the preparation and application method of impregnating agent in the present embodi...

Embodiment 2

[0047] In this example, the impregnating agent is also a glue solution prepared by mixing 15% flexible graphite, a total amount of 5% treating agent and 85% water; the difference from Example 1 is that the flexible graphite in this example The composition also meets the following requirements:

[0048] 1. Expandable graphite with expansion temperature between 60℃-100℃ accounts for 0%, expandable graphite with expansion temperature between 100℃-300℃ accounts for 7.5%, and expandable graphite with expansion temperature above 300℃ accounts for 7.5% %.

[0049] 2. In this embodiment, the mass fraction ratios in the total impregnating agent are respectively 2% of ammonium persulfate oxidant, 1% of γ-aminopropyl triethoxysilane coupling agent, and 1% of sodium lignosulfonate dispersant. %, potassium chloride thickener 1%.

[0050] The specific steps of its processing method are the same as those in Example 1.

[0051] The obtained air permeability test result is 0.58nPm; the air ...

Embodiment 3

[0053] In this embodiment, the impregnating agent is a glue solution prepared by mixing 20% flexible graphite, 7.5% treating agent and 77.5% water in total;

[0054] In this embodiment, the flexible graphite satisfies the following conditions:

[0055] 1. Expandable graphite with expansion temperature between 60℃-100℃ accounts for 10%, expandable graphite with expansion temperature between 100℃-300℃ accounts for 5%, and expandable graphite with expansion temperature above 300℃ accounts for 5%. %.

[0056] 2. In this example, the mass fraction of the total impregnating agent is 3% of ammonium persulfate oxidant, 1.5% of γ-aminopropyl triethoxysilane coupling agent, and 1.5% of sodium lignosulfonate dispersant. %, potassium chloride thickener 1.5%.

[0057] The specific steps of its processing method are the same as those in Example 1.

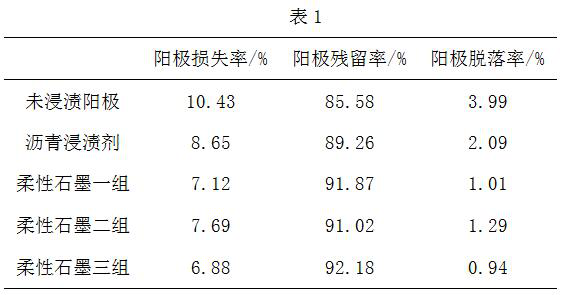

[0058] The obtained air permeability test result is 0.50nPm; the air reactivity test result is that the anode carbon block loss rate is 6....

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com