Welding system for aluminum alloy laser welding and surface treatment method

A laser welding and welding system technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., to achieve the effect of simple and easy-to-operate surface treatment method, good welding quality, and improved welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

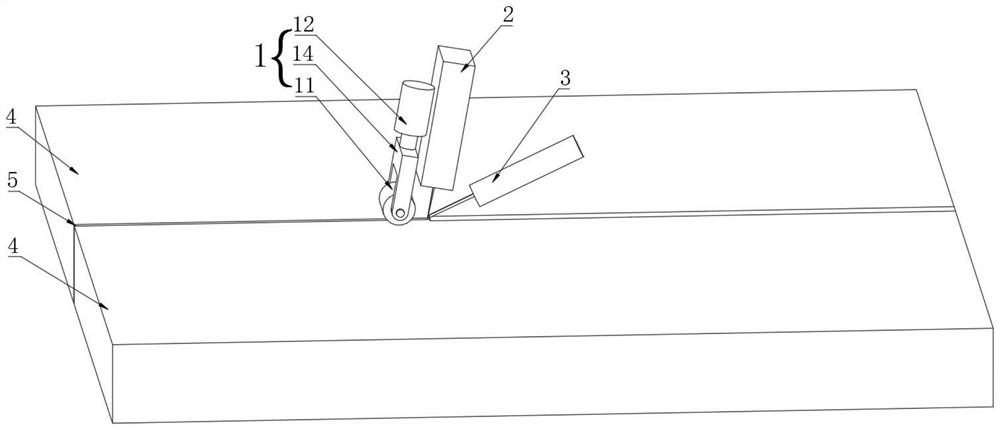

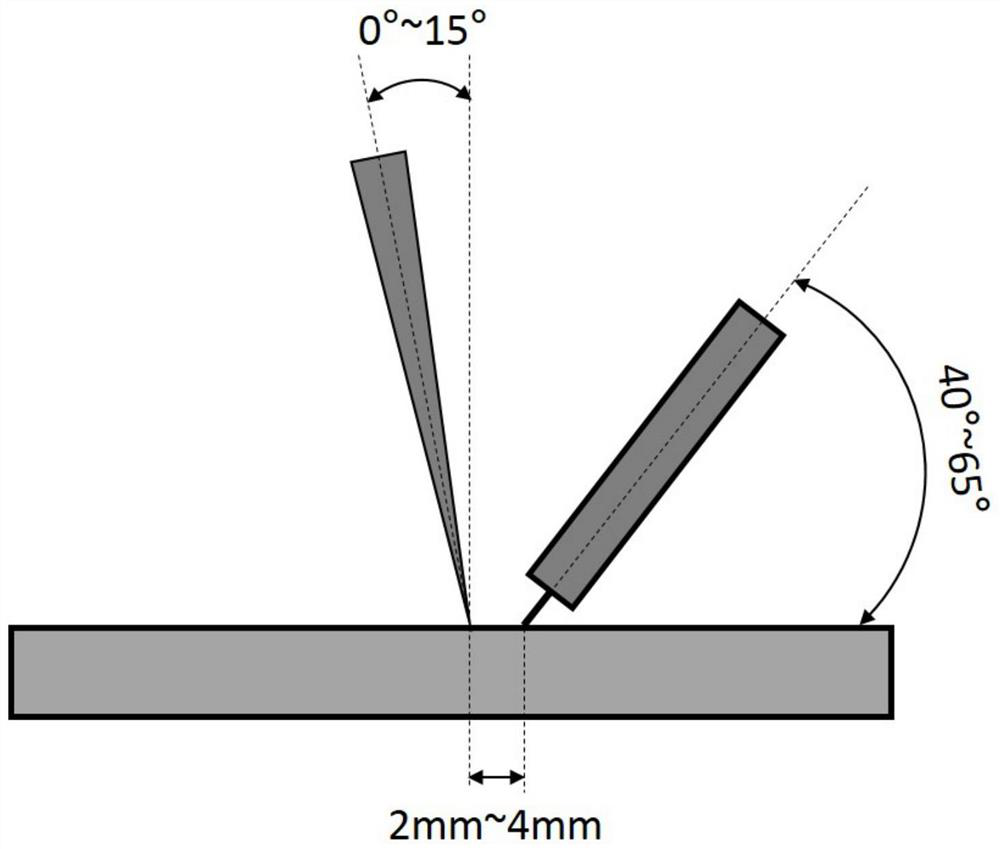

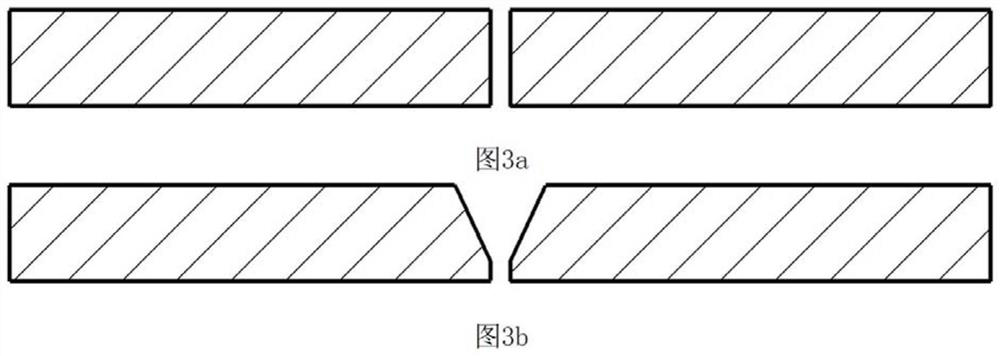

[0034] On the one hand, if Figure 1 to Figure 4 As shown, the present invention provides a welding system for aluminum alloy laser welding, including a workbench, a surface processing device 1, a laser welding device 2 and an arc welding device 3, the workbench is used to fix the parts to be welded 4 and A weld seam 5 is reserved between the parts to be welded 4, the surface processing device 1 includes a roller 11 and a hydraulic control mechanism 12, the roller 11 abuts on the parts to be welded 4 and is located at the top of the weld seam 5, the The output end of the hydraulic control mechanism 12 is arranged on the top of the roller 11, the outer surface of the roller 11 is provided with a hard particle layer 13, and the laser welding device 2 and the arc welding device 3 are successively arranged on the surface along the direction opposite to the welding direction. One side of the processing device 1. It should be noted that the hydraulic control mechanism 12 is arrange...

Embodiment 2

[0047] On the basis of the above technical solutions, if Figure 5 As shown, it also includes a blowing device 6 for removing metal debris. The blowing device 6 includes an air source and a nozzle 61. One end of the nozzle 61 is connected to the air source, and the other end is correspondingly arranged on the roller 11 and the laser welding device 2. Between; the metal debris produced by the rollers to be welded can be cleaned in time to prevent welding defects such as impurities. Specifically, the gas source (not shown) on the blowing device 6 and the laser welding device 2 can share a set of shielding gas supply system, the shielding gas gas adopts the combination inert gas of argon and helium, the The nozzle 61 is correspondingly arranged on one side of the position between the roller 11 and the laser welding device 1 , and blows off the metal debris that may be produced on the surface of the part 4 to be welded after being rolled by the roller 11 from the side.

[0048] O...

Embodiment 3

[0050] On the basis of the above-mentioned technical solution, a vibrator (not shown in the figure) is also included, and the vibrator is arranged on the hydraulic control mechanism 12; its vibration direction is parallel to the direction in which the hydraulic control mechanism 12 applies pressure to the rollers to vibrate up and down , the vibration direction is as Figure 5 As shown by the middle arrow, the pressure of the roller 11 on the part 4 to be welded can be increased, which is beneficial to the damage of the oxide film on the surface of the aluminum alloy, increases the surface roughness of the part 4 to be welded, facilitates subsequent welding operations, and has good welding quality. Specifically, the vibrator adopts a hydraulic vibration motor, which can be obtained from the prior art, and will not be repeated here.

[0051] On the other hand, the surface treatment method for aluminum alloy laser welding in this embodiment is basically the same as that in Embod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com