Magnetic polymer composite particle as well as preparation method and application thereof

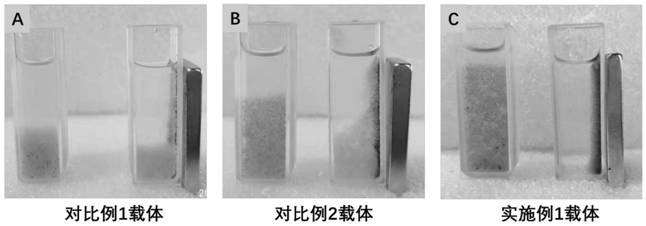

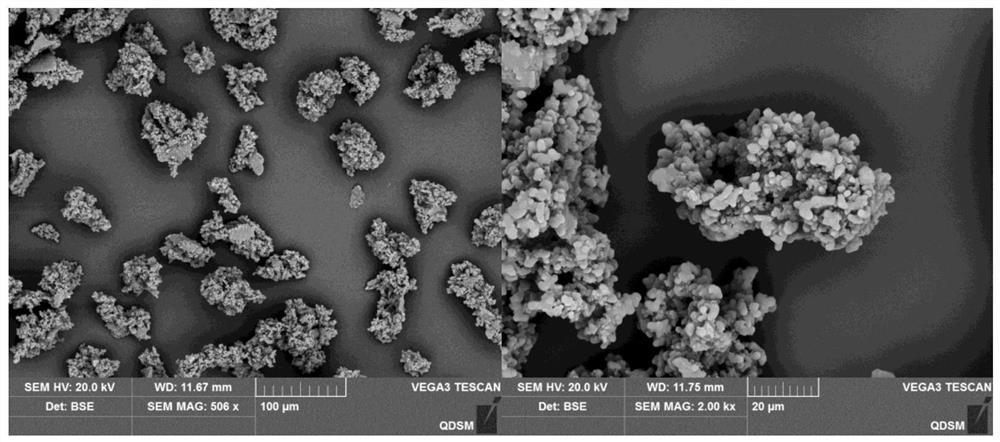

A technology of composite particles and polymers, applied in the field of composite materials, can solve the problems of natural mineral quality, particle size, pore size difference, soil effectiveness reduction, insufficient mechanical strength, etc., and achieve good superparamagnetism and thermal stability , short synthesis cycle, uniform particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

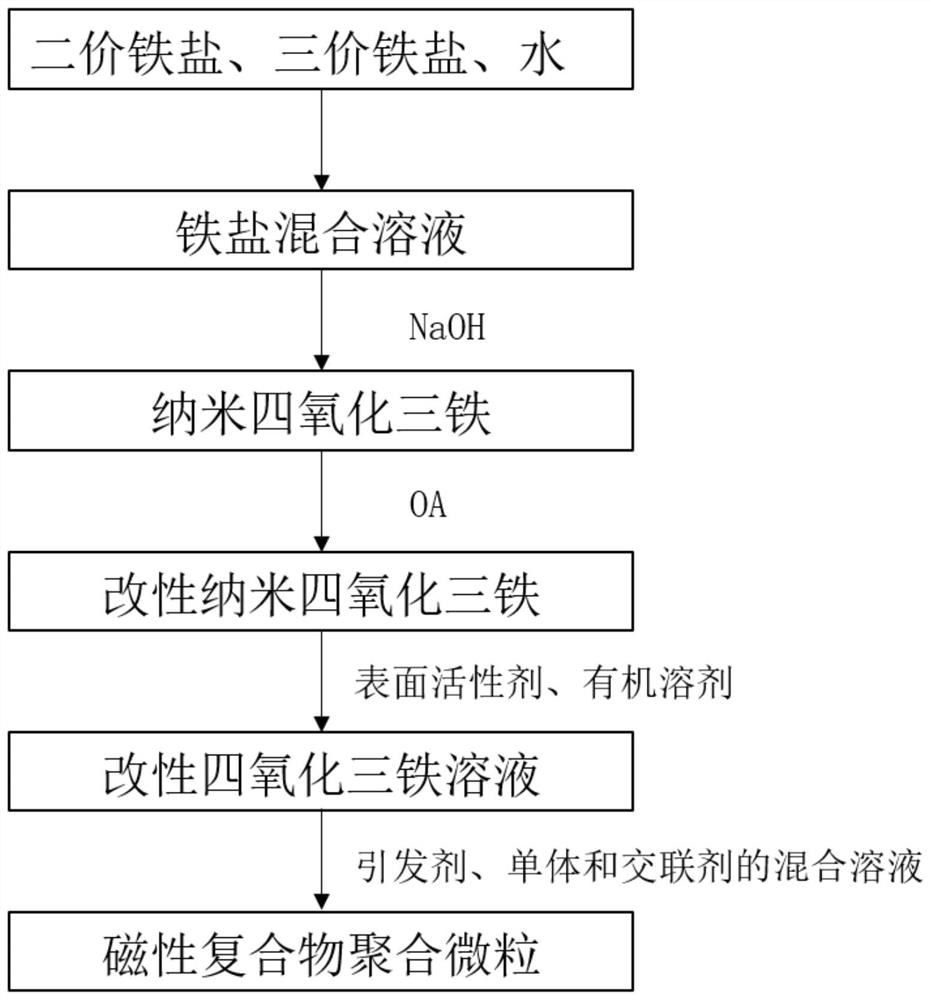

Method used

Image

Examples

Embodiment 1

[0044] (1) Add 4.5 g of ferrous chloride tetrahydrate and 12 g of ferric chloride hexahydrate into a reactor filled with 75 mL of pure water, stir mechanically at 55°C until the iron salt is completely dissolved, and add 5 mol / L of hydroxide Sodium solution to pH = 9, heat preservation reaction for 1h, to obtain a mixed solution of iron salt;

[0045] (2) Drop 5 g of oleic acid into the iron salt mixed solution described in step (1), heat up to 75° C., and keep warm for 1 h;

[0046] (3) Add 75 mL of ethanol and 4 g of sodium lauryl sulfate directly to the system obtained in step (2), keep stirring for 1 h, add 2 g of potassium persulfate into the system, and then add 20 mL of styrene and divinyl sulfate dropwise to the system. Benzene 4mL mixed solution, after the dropwise addition, keep stirring for 2h;

[0047] (4) Filter the system obtained in step (3) to obtain solid matter, wash twice with 75% ethanol, and vacuum-dry to constant weight to obtain magnetic polymer composi...

Embodiment 2

[0049] (1) Add 5 g of ferrous chloride tetrahydrate and 12 g of ferric chloride hexahydrate into a reactor filled with 75 mL of pure water, mechanically stir at 45 °C until the iron salt is completely dissolved, and add 5 mol / L of sodium hydroxide dropwise Solution to pH = 9, heat preservation reaction 1.5h, to obtain iron salt mixed solution;

[0050] (2) Add 10 g of oleic acid dropwise to the iron salt mixed solution described in step (1), heat up to 75° C., and keep warm for 30 minutes;

[0051] (3) Add 75 mL of ethanol and 4 g of sodium lauryl sulfate directly to the system obtained in step (2), heat and stir for 30 min, add 2.2 g of azobisisoheptanonitrile to the system, and then add benzene dropwise to the system A mixed solution of ethylene 16mL, glycidyl methacrylate 4mL and divinylbenzene 3mL, after the dropwise addition, keep stirring for 1h;

[0052] (4) Filter the system obtained in step (3) to obtain solid matter, wash twice with 75% ethanol, and vacuum-dry to co...

Embodiment 3

[0054] (1) Add 6g of ferrous chloride tetrahydrate and 12g of ferric chloride hexahydrate into a reactor filled with 75mL of pure water, stir mechanically at 65°C until the iron salt is completely dissolved, and add 5mol / L sodium hydroxide dropwise Solution to pH = 9, heat preservation reaction for 2 hours, to obtain a mixed solution of iron salt;

[0055] (2) Drop 6 g of oleic acid into the iron salt mixed solution described in step (1), heat up to 65° C., and keep warm for 1 h;

[0056] (3) Add 75 mL of ethanol and 4.5 g of sodium dodecylsulfonate directly to the system obtained in step (2), keep stirring for 1 hour, add 1.8 g of azobisisobutyronitrile into the system, and then dropwise add A mixed solution of styrene 16mL, methacryloyloxyethyltrimethylammonium chloride 6mL and divinylbenzene 2mL, after the dropwise addition, keep stirring for 4h;

[0057] (4) Filter the system obtained in step (3) to obtain solid matter, wash twice with 75% ethanol, and vacuum-dry to const...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com