High-strength and high-elasticity graphene aerogel free of slag falling and preparation method thereof

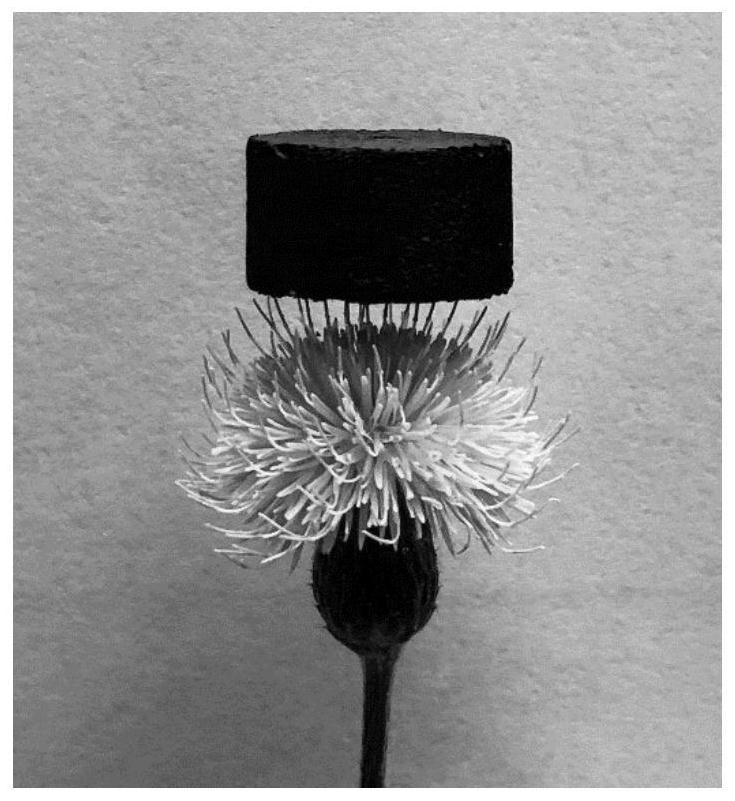

A graphene airgel, high-strength technology, applied in graphene, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of large environmental pollution, environmental protection, and graphene airgel slag drop, and achieve excellent return Elastic performance, ultra-high thermal insulation ability, and the effect of improving mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

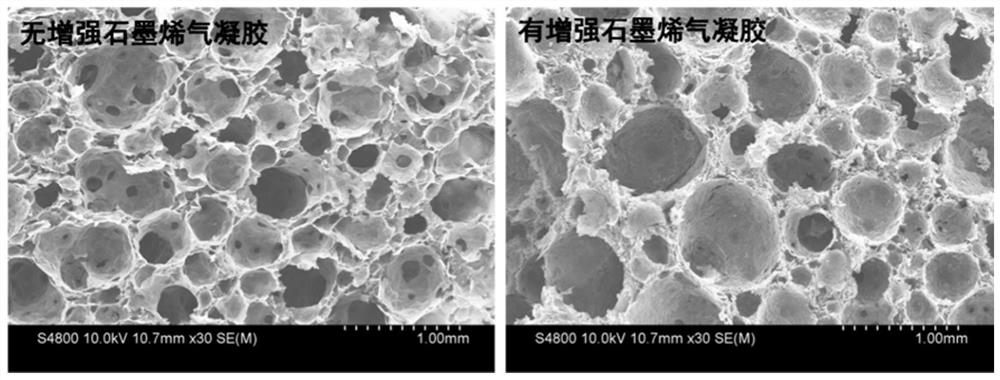

[0032] The present invention provides a method of preparing a high-strength high-elastic graphene gas gel without removing slag, the method comprising the steps of:

[0033] (1) Uniformly mix the oxidation graphene solution, dimethylsiloxane oligomer, and the alkaline catalyst, and then reacted with pre-hydrolysis and pre-woven, to obtain a predetermined graphene precursor; in the present invention, The oxidation graphene solution is an oxide in grapiene aqueous solution; in the present invention, the dimethylsiloxane is inexhate after mixing the oxide in graphene solution, dimethylsiloxane oligomer, and the alkaline catalyst. The polymer is prehydrolyzed under the action of the alkaline catalyst, resulting in a prehyd hydrolyzed dimethylsiloxane oligomer, and the resulting prehyd monomethylsiloxane oligomer is said to the oxide oxide layer The pre-structure (i.e., pre-spoken) is performed at the edge of the upper and lower sides and the oxide oxide to obtain a predetermined oxide...

Embodiment 1

[0051] 1 Single-layer oxide solution of 50 ml of concentration of 20 mg / ml, 0.3 g of dimethylsiloxane oligomer PDMSSSSSSSSSSSSSSELGARD 184 A gum and 0.01 g of concentrated ammonia water (ammonia in concentrated ammonia is 28%), Uniform mixing was mixed with magnetic stirring, pre-hydrolysis and pre-woven reaction for 2 h were stirred at room temperature, resulting in a preparation of the oxide oxide precursor.

[0052] 2 Add 0.5 g of the alkyl glycosidin, 4G reductant disulfuritol, and 0.03 g of dimethylsiloxane crosslinker PDMS Sylgard184B glue, stirring and mixing Sol gel and crosslinking reaction at a high temperature of 120 ° C for 24 h, resulting in a modified graphene wet gel.

[0053] 3 The above-described modified graphene wet gel is placed in a refrigerator having a temperature of -40 ° C to freeze overnight, then placed in a cryogenic dryer, and the inside of the freeze dryer is controlled below 20 Pa, and the temperature is controlled at 25. After 48 h, lyophilized fo...

Embodiment 2

[0055] 1 Single layer oxide solution of 50 ml of concentration of 20 mg / ml, 0.1 g of dimethylsiloxane oligomers PDMSSSSSSSSSSSYLGARD 184 A glue and 0.001 g of concentrated ammonia water (the mass fraction of ammonia contained in concentrated ammonia is 28%), It was mixed with mixing with magnetic stirring, pre-hydrolysis and pre-woven reaction 12 h were prepared at room temperature, resulting in a prehydrolysis and prefluential precursor.

[0056] 2 Add 0.5 g of the alkyl glycosidin, 4G reducing agent disulfurol and 0.01 g of dimethylsiloxane crosslinker PDMS Sylgard184B, and stir well Sol gel and crosslinking reaction at a high temperature of 120 ° C for 24 h, resulting in a modified graphene wet gel.

[0057] 3 The above-described modified graphene wet gel is placed in a refrigerator having a temperature of -40 ° C to freeze overnight, then placed in a cryogenic dryer, and the inside of the freeze dryer is controlled below 20 Pa, and the temperature is controlled at 25. After ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com