Activated carbon treatment method and method for removing heavy hydrocarbon by natural gas liquefaction adsorption method

A treatment method and activated carbon technology, applied in chemical instruments and methods, gas fuels, other chemical processes, etc., can solve problems such as inability to remove heavy hydrocarbons, inability to remove heavy hydrocarbons normally, and blockage of heat exchangers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

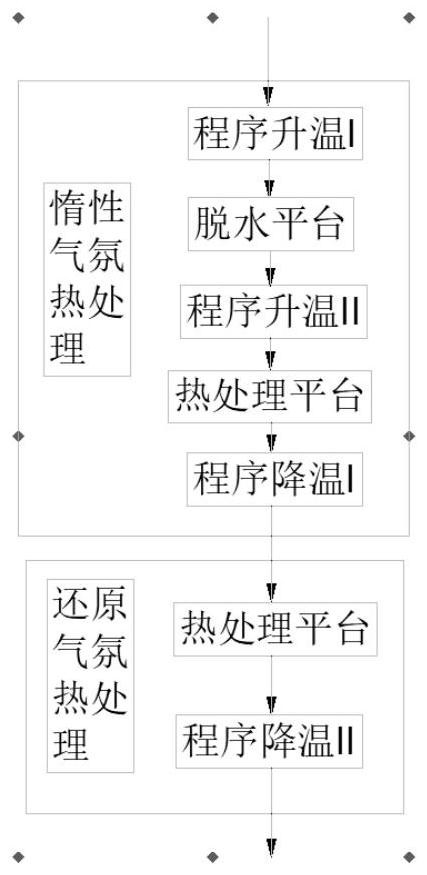

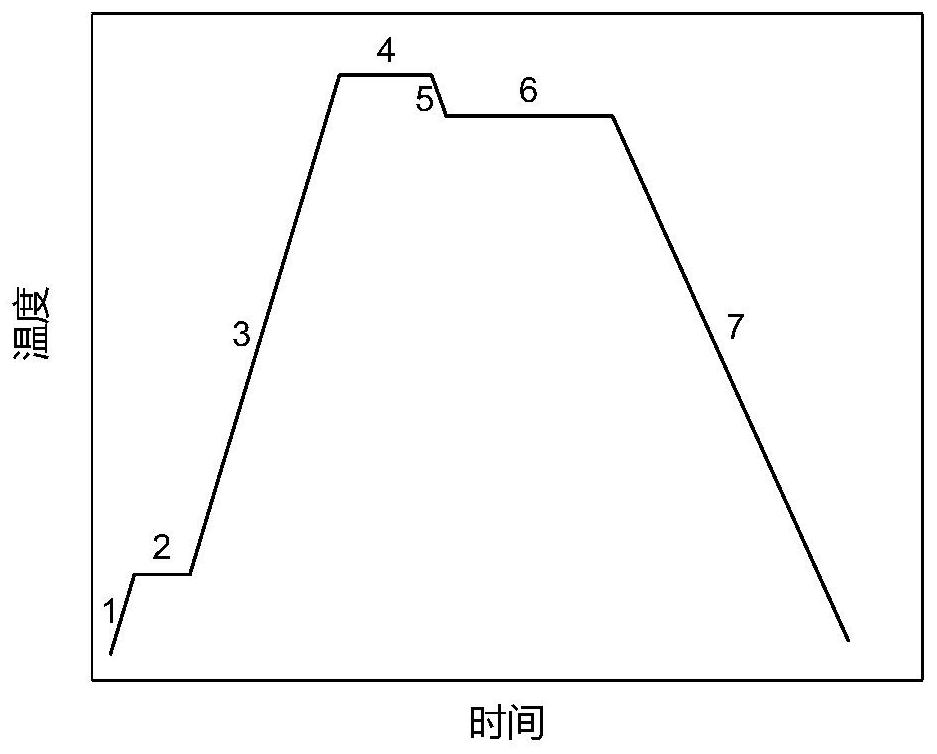

Method used

Image

Examples

Embodiment Construction

[0034] In order to further illustrate the present invention, a kind of activated carbon processing method provided by the present invention and the method for deheavy hydrocarbons by natural gas liquefaction adsorption method are described in detail below in conjunction with embodiment, but they can not be interpreted as limiting the protection scope of the present invention. In order to more intuitively illustrate the differences in the physical and chemical properties and adsorption performance of the activated carbon treated by the method of the present invention, the physical and chemical properties and adsorption performance of the activated carbon treated in the examples and comparative examples were compared by means of comparative examples.

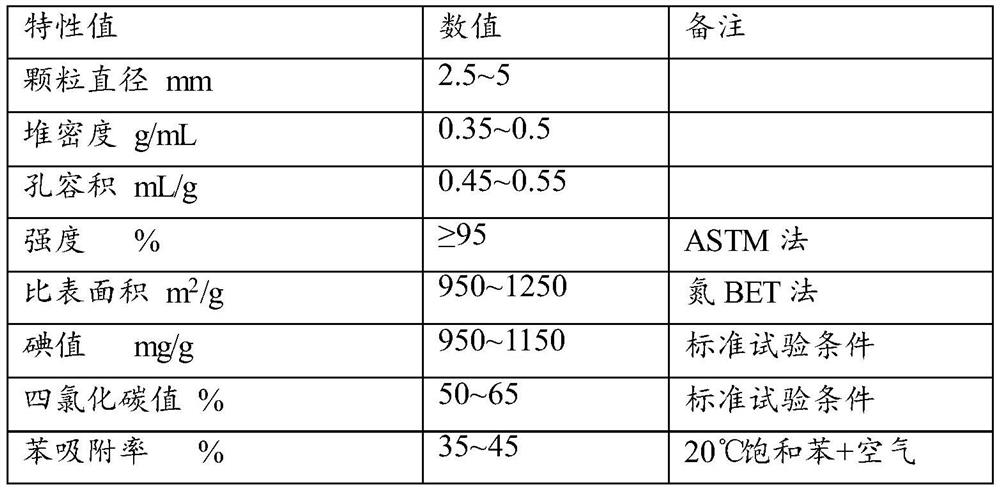

[0035] The physical and chemical properties of the activated carbon raw material adopted in the following examples are shown in Table 3:

[0036] Table 3 Physical and chemical properties of activated carbon raw materials

[0037] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com