Negative-electrode-free lithium secondary battery

A lithium secondary battery and negative electrode technology, applied in the direction of lithium batteries, negative electrodes, battery electrodes, etc., can solve the problem of poor cycle of batteries without negative electrodes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

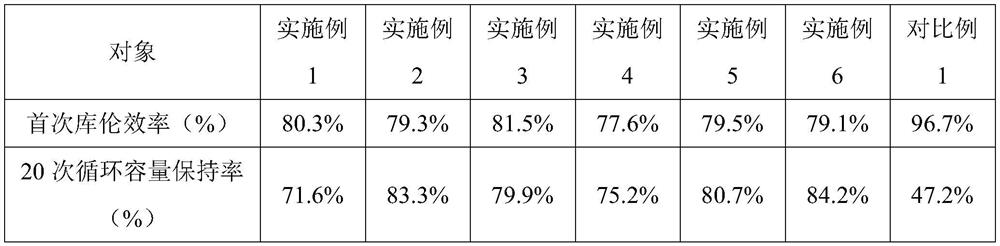

Examples

preparation example Construction

[0026] The preparation method of the above-mentioned non-negative electrode lithium secondary battery comprises the following steps:

[0027] 1) Preparation of the positive electrode: adding the above-mentioned lithium-containing material, a conductive agent and a binder whose first effect is less than 85% to the solvent, and mixing uniformly to obtain a positive electrode slurry; uniformly coating the positive electrode slurry on the positive electrode current collector, After drying, evenly coat the insulating coating slurry on the surface of the positive electrode with a thickness of 1-20 μm, and roll to obtain the positive electrode;

[0028] Preparation of insulating coating slurry: Dissolve a certain amount of binder in NMP, stir until transparent, add inorganic ceramic materials and an appropriate amount of NMP in a certain proportion, add a little dispersant and stir for 30 minutes, then add the above binder The binder glue was stirred for another 30 minutes;

[0029]...

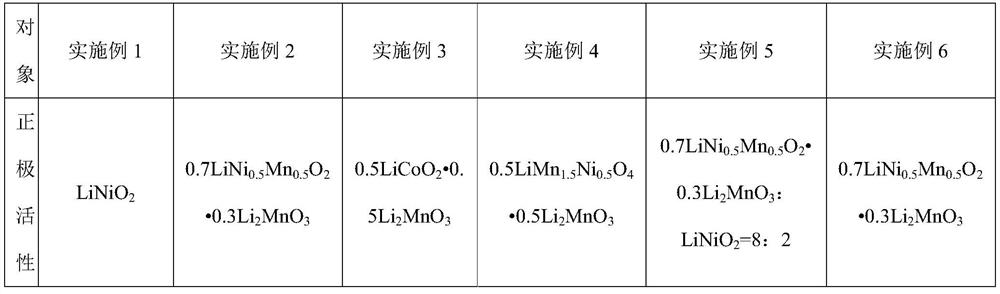

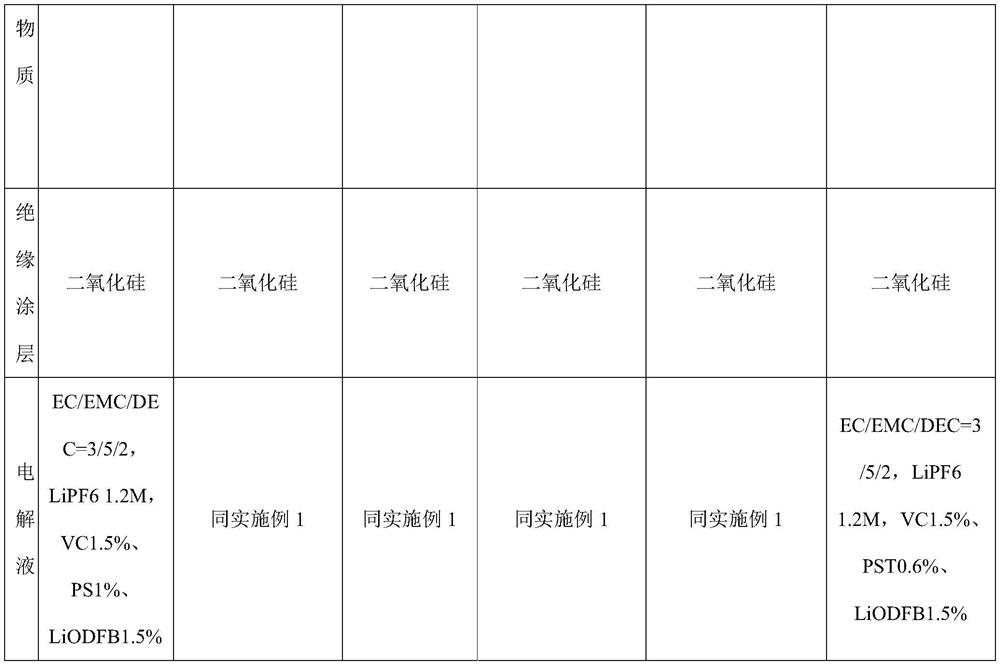

Embodiment 1

[0040] The anode-free lithium secondary battery of this embodiment includes a cathode (1), an anode (2), a separator (3) and an electrolyte (4).

[0041] (1) Positive electrode

[0042] The positive electrode includes an active material layer coated on a positive electrode current collector and an insulating coating layer coated on the active material layer.

[0043] The active material layer is composed of a lithium-containing material whose first effect is less than 85%, a conductive agent and a binder. The lithium-containing material is LiNiO 2 , the conductive agent is carbon black. The binder is polyvinylidene fluoride (PVDF). Lithium-containing material LiNiO 2, The mass ratio of conductive agent carbon black to binder polyvinylidene fluoride (PVDF) is 95:2:3.

[0044] The insulating coating is mainly composed of inorganic ceramic materials and binders (the other components are a little dispersant), of which the inorganic ceramic materials SiO 2 Accounted for 93%, ...

Embodiment 2

[0060] The difference between the anode-free lithium secondary battery of this embodiment and that introduced in Embodiment 1 is that the positive active material is 0.7LiNi 0.5 mn 0.5 o 2 0.3 Li 2 MnO 3 , other unspecified points are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com