Preparation method and observation method of medium manganese steel metallographic specimen

A metallographic sample, manganese steel technology, applied in the field of medium manganese steel metallographic sample preparation, can solve the problems of unclear metallographic structure, unsatisfactory metallographic corrosion effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The invention provides a method for preparing a medium manganese steel metallographic sample, comprising the following steps:

[0031] (1) The medium manganese steel is subjected to rough grinding and fine grinding successively to obtain a polished sample;

[0032] (2) electropolishing the polished sample obtained in the step (1) to obtain a polished sample; the electrolytic solution of the electropolishing includes perchloric acid glacial acetic acid solution or perchloric acid alcohol solution;

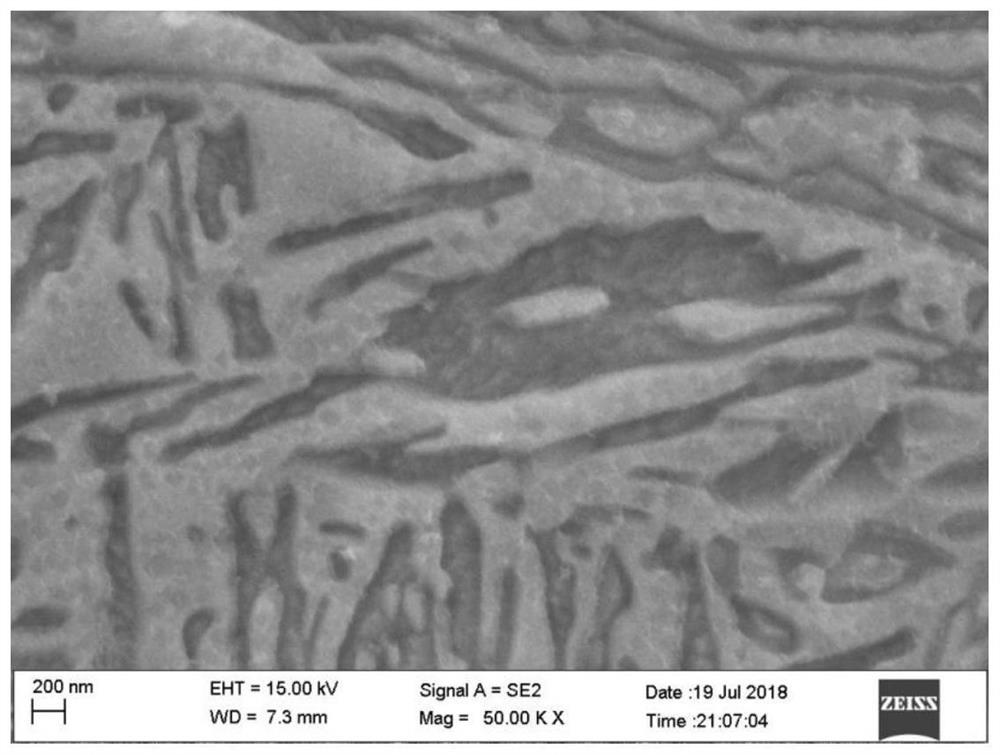

[0033] (3) Soak the polished sample obtained in the step (2) in sodium bisulfite solution for corrosion to obtain a metallographic sample of medium manganese steel.

[0034] The preparation method provided by the invention is applicable to medium manganese steel obtained by various thermal processing and heat treatment, preferably suitable for medium manganese steel containing ferrite and austenite structure. In the present invention, there is no special limitation on the pr...

Embodiment 1

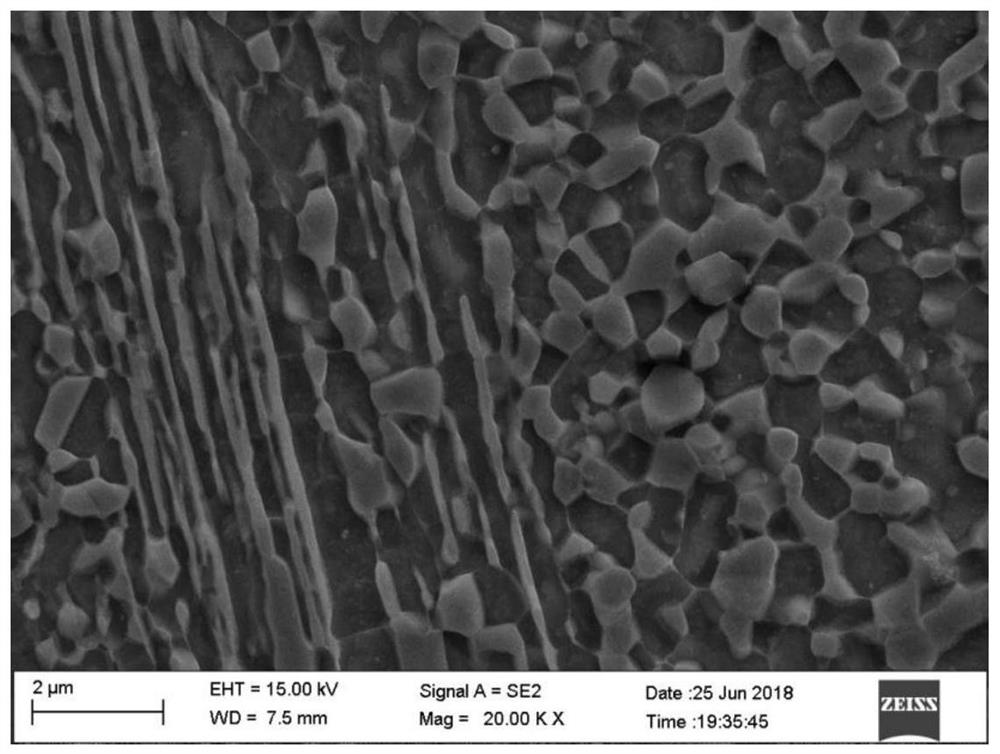

[0056] The preparation method of medium manganese steel metallographic sample is the following steps:

[0057] (1) Process the medium manganese steel into a square sheet with a size of 10mm and a thickness of 0.4mm by wire cutting machine, and then pass it through 120 # 、240 # 、400 # and 800 # Grinding with silicon carbide sandpaper to obtain a sample with a thickness of 120 μm, and then after 1200 # Grinding with silicon carbide sandpaper to obtain a sample with a thickness of 60 μm, and finally punching to obtain a polished sample with a diameter of 3 mm; wherein, the fine grinding method is in the form of drawing "8";

[0058] The preparation method of medium manganese steel is as follows:

[0059] 1) Pretreatment before rolling: put the billet into a heating furnace and heat it from room temperature to 1200°C, and keep it warm for 4 hours to obtain a pretreated billet;

[0060] 2) hot rolling: the pretreated billet obtained in step 1) is first hot-rolled, then water-q...

Embodiment 2

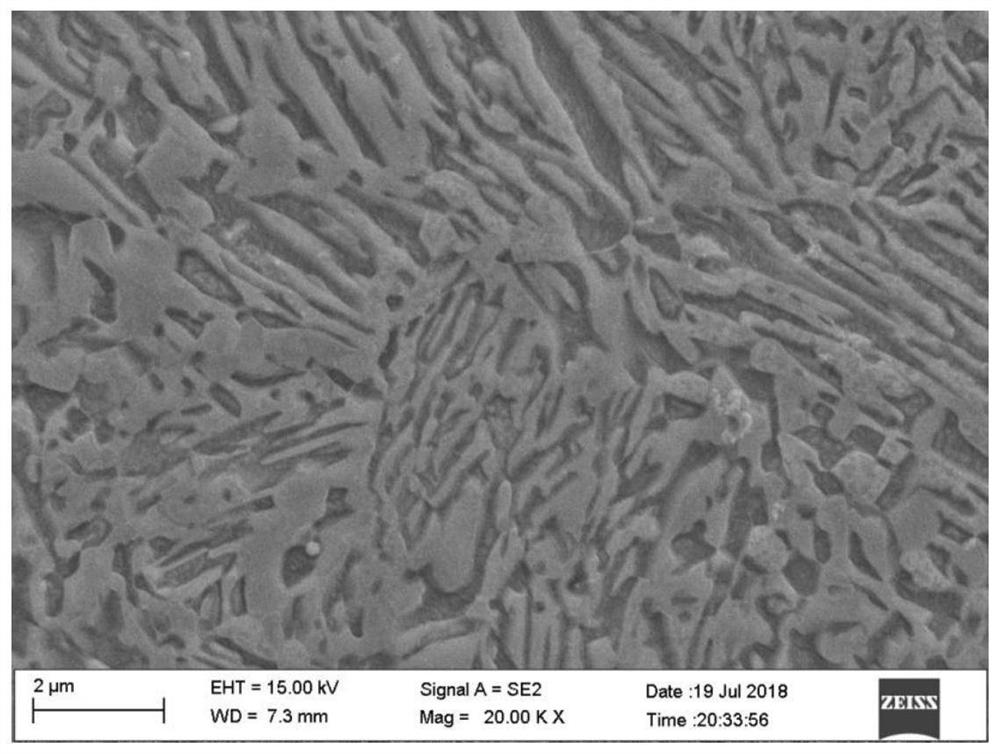

[0066] The preparation method of medium manganese steel metallographic sample is the following steps:

[0067] (1) Process the medium manganese steel into a square sheet with a size of 10mm and a thickness of 0.4mm by wire cutting machine, and then pass it through 120 # 、240 # 、400 # and 800 # Grinding with silicon carbide sandpaper to obtain a sample with a thickness of 120 μm, and then after 1200 # Grinding with silicon carbide sandpaper to obtain a sample with a thickness of 60 μm, and finally punching to obtain a polished sample with a diameter of 3 mm; wherein, the fine grinding method is in the form of drawing "8";

[0068] The preparation method of medium manganese steel is as follows:

[0069] 1) Pretreatment before rolling: put the billet into a heating furnace and heat it from room temperature to 650°C, and keep it warm for 5 minutes to obtain a pretreated billet;

[0070] 2) Warm rolling: Warm rolling the pretreated steel slab obtained in step 1), and then imme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com