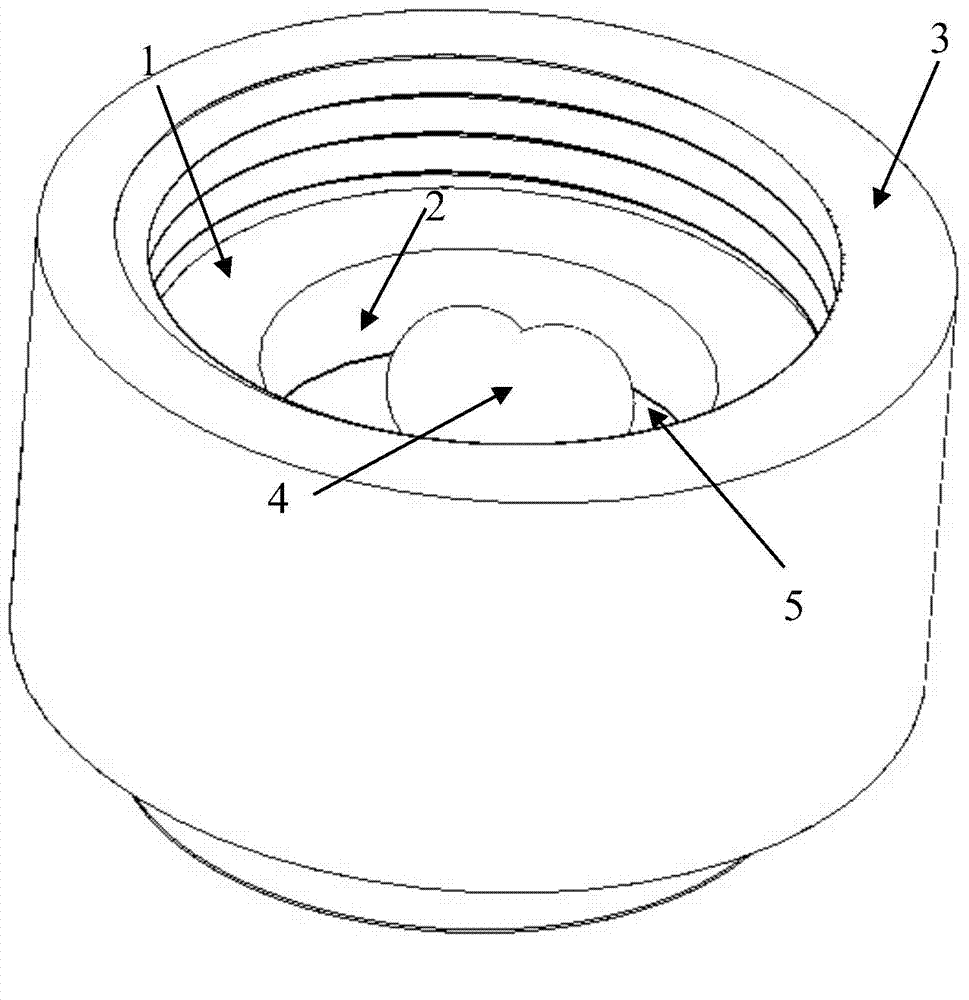

Articular cartilage microstructure nanoindentation inlaying and water-retaining sample stage and experiment method

A technology of articular cartilage and nano-indentation, which is used in the preparation of test samples and the application of stable tension/pressure to test the strength of materials. It can solve the problems of cartilage surface dehydration and difficult surface treatment of cartilage samples, and achieve mechanical properties. reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

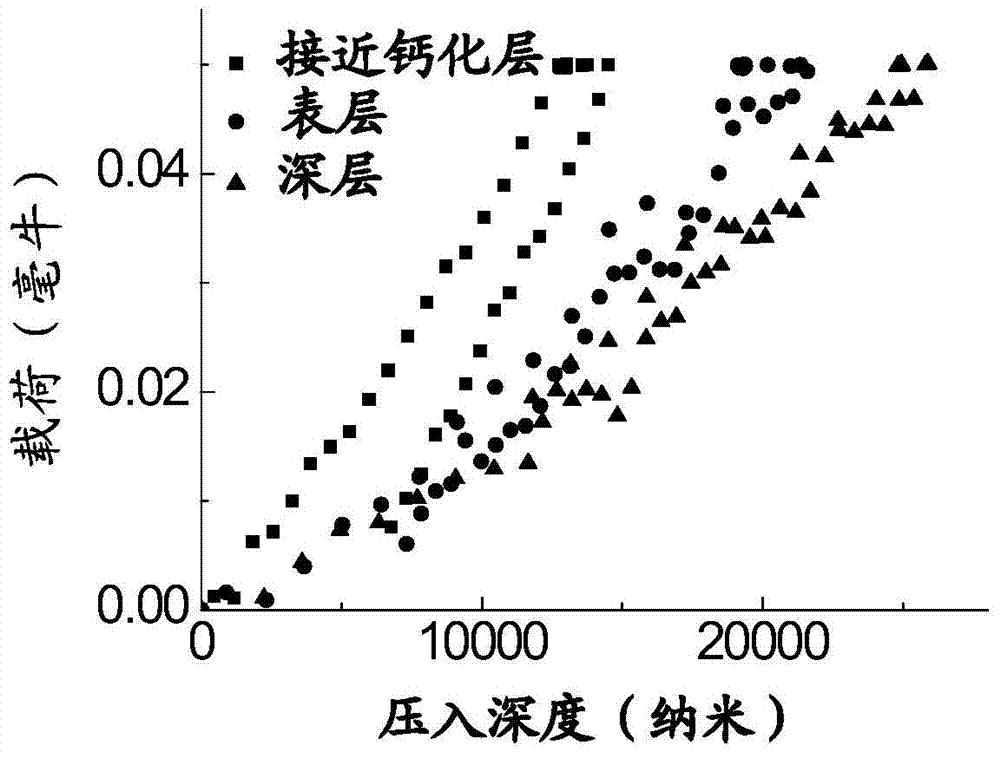

[0018] Such as figure 2 Shown are the test results of the static mechanical properties of the articular cartilage microstructure, and the mechanical properties of the rabbit articular cartilage microstructure were tested using the nano-indentation mosaic water-retaining sample platform of the articular cartilage microstructure. Cut the rabbit femur including the articular cartilage into a section 2 cm high, mix bisphenol A and epichlorohydrin at a volume ratio of 1:1, stir well, pour it into the holding tank, insert the articular subchondral bone into the resin, and clamp it with tweezers The ligament on the articular cartilage adjusts the height of the articular cartilage so that it is 1mm higher. Keep it for ten minutes and wait for the resin to solidify. Turn the table body upside down on 4000-grit sandpaper, finely grind for 2 minutes, turn 6000-grit sandpaper to polish for 2 minutes; rotate the sleeve so that the sleeve is 2 mm higher than the upper edge of the table bod...

Embodiment 2

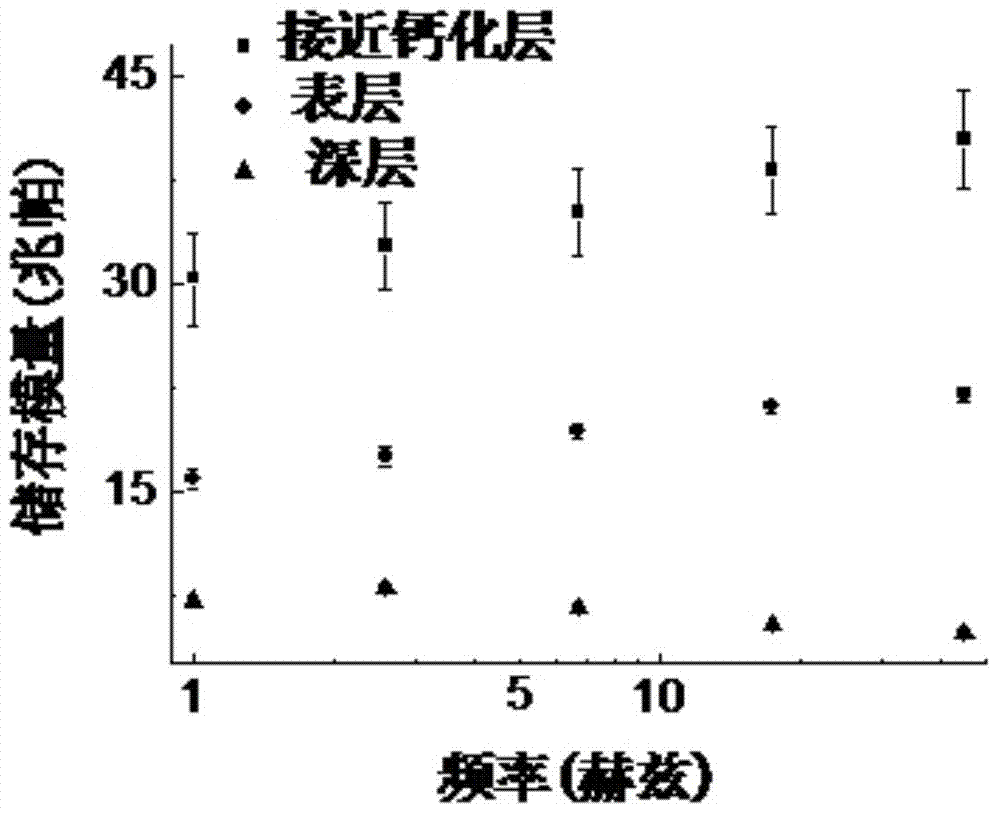

[0019] Such as image 3 Shown are the test results of the dynamic mechanical properties of the articular cartilage microstructure. Nano-indentation method was used to detect the mechanical properties of the rabbit articular cartilage microstructure. Mix 1:1, stir evenly, pour into the holding tank, insert the articular subchondral bone into the resin, clamp the articular cartilage ligament with tweezers, adjust the height of the articular cartilage to be 1mm higher; keep it for ten minutes, and wait for the resin to solidify Grind the table body upside down on 4000-mesh sandpaper for 2 minutes, turn to 6000-mesh sandpaper and polish for 2 minutes; rotate the sleeve so that the sleeve is 2 mm higher than the upper edge of the table body; install the tested sample table into the nanoindentation instrument On the card table, select the relevant method of dynamic mechanical performance test, locate the point to be tested, the maximum loading frequency is 50 Hz, and measure 20 poin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com