Electrochromic film layer structure as well as preparation method and application thereof

A technology of electrochromic film and electrochromic device, applied in coating, metal material coating process, ion implantation plating, etc., can solve problems such as poor temperature resistance, achieve suppressed attenuation, increase optical modulation amplitude and Effect of coloring efficiency and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] Another aspect of the embodiments of the present invention also provides a method for preparing the aforementioned electrochromic film layer structure, which includes:

[0043] providing a substrate provided with a transparent conductive layer;

[0044] Depositing a tungsten oxide layer on the surface of the transparent conductive layer by using magnetron sputtering technology, using a tungsten oxide target as a target;

[0045] And, using the magnetron sputtering technology, using the zinc-tin oxide target as the target material, an amorphous zinc-tin oxide buffer layer is deposited on the surface of the tungsten oxide layer, thereby obtaining an electrochromic film layer structure.

[0046]In some more specific embodiments, the mass ratio of zinc oxide to tin oxide in the zinc-tin oxide target is 100:(50-200).

[0047] Further, the sputtering method adopted by the magnetron sputtering technology includes radio frequency sputtering or intermediate frequency sputtering...

Embodiment 1

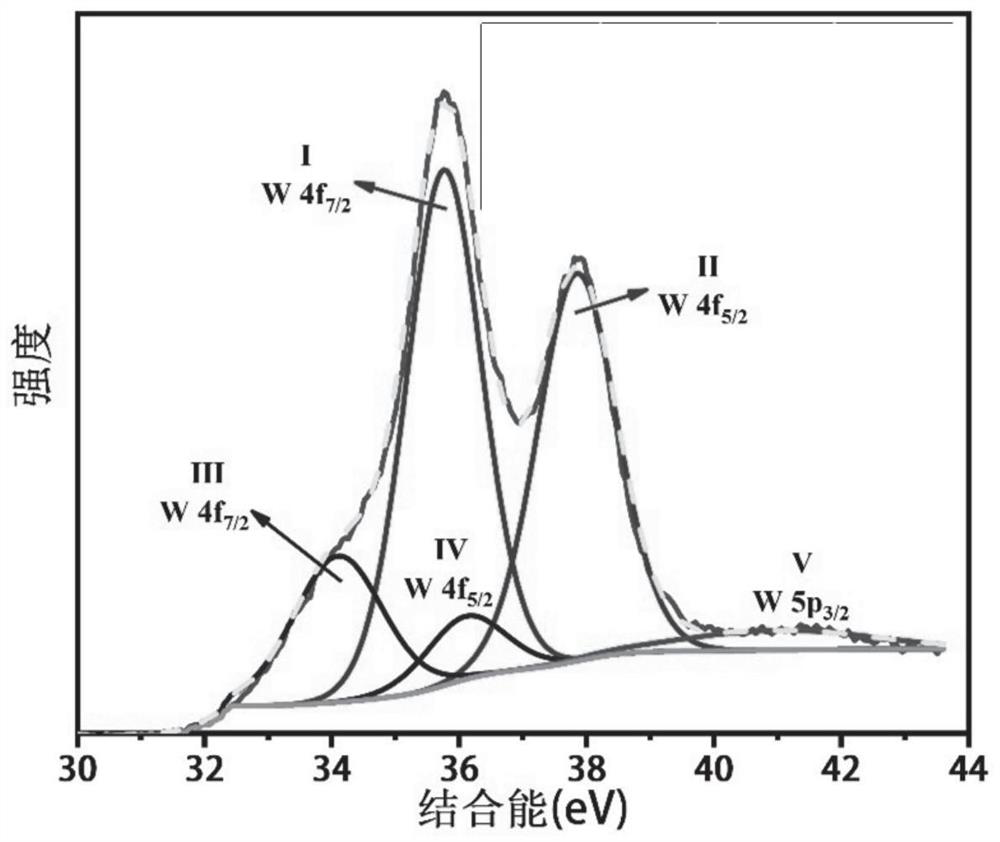

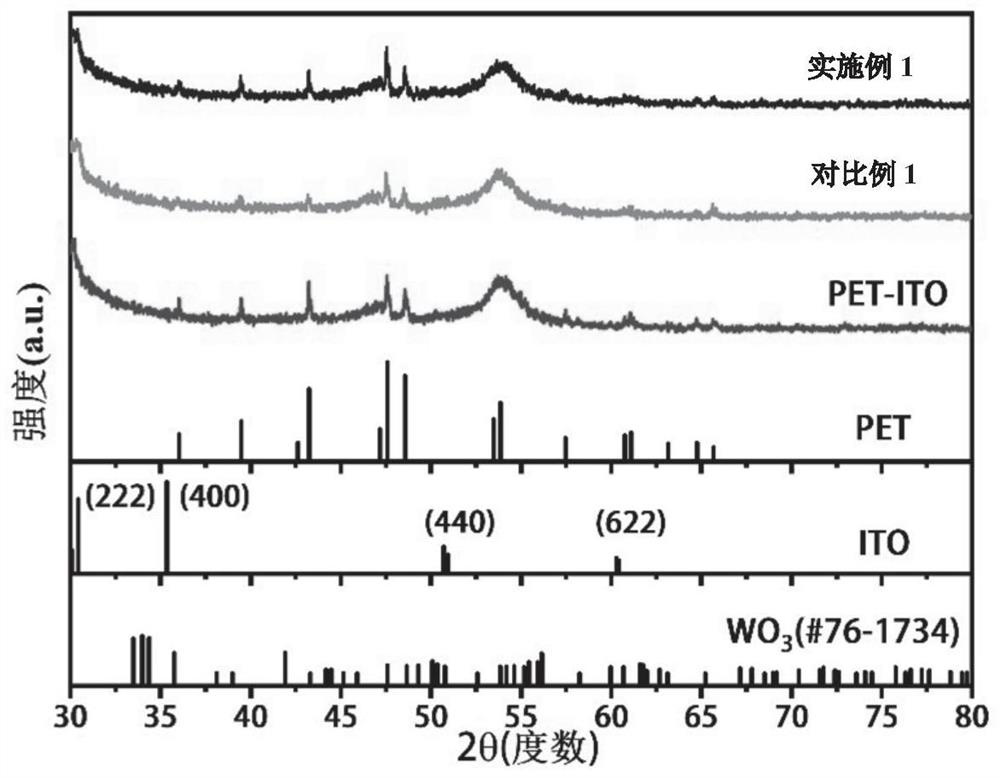

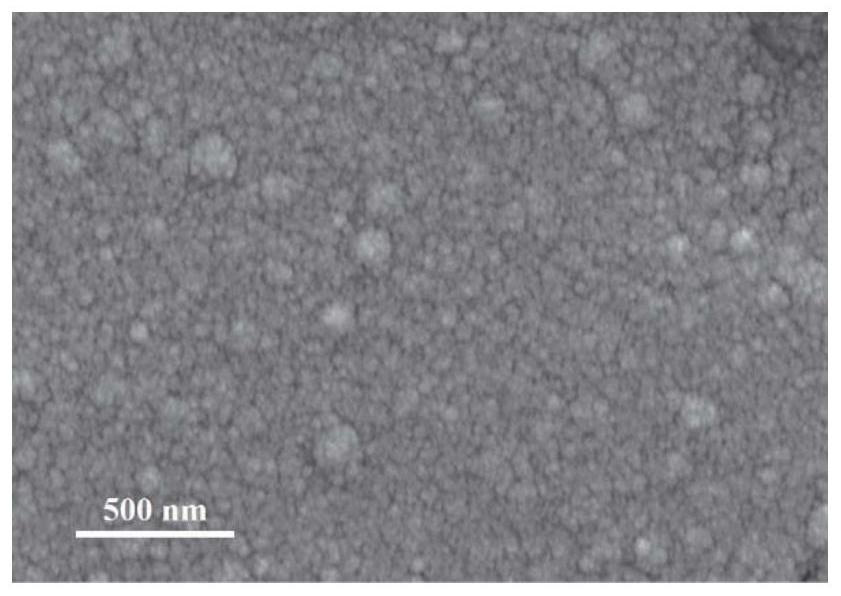

[0068] (1) Magnetron sputtering deposition of nano-columnar tungsten oxide layer

[0069] The tungsten oxide target is placed in the magnetron sputtering coating equipment, and the nano columnar tungsten oxide layer is deposited on the PET substrate covered with the ITO transparent conductive layer. The parameters in the sputtering process are as follows: the sputtering method is radio frequency sputtering or intermediate frequency sputtering, and the working gas is O 2 and Ar, where O 2 The flow ratio of Ar and Ar is 1:4; the substrate temperature is 80°C; the vacuum degree is 5×10 -2 Pa; the sputtering pressure value is 1.2Pa; the sputtering power density is 4.7W / cm 2 ; The thickness of the tungsten oxide layer is 300nm;

[0070] (2) Magnetron sputtering deposition of amorphous ZnO buffer layer

[0071] The zinc-tin oxide target is placed in the magnetron sputtering coating equipment, and the amorphous zinc-tin oxide buffer layer is deposited on the ITO transparent condu...

Embodiment 2

[0089] (1) Magnetron sputtering deposition of nano-columnar tungsten oxide layer

[0090] The tungsten oxide target is placed in the magnetron sputtering coating equipment, and the nano columnar tungsten oxide layer is deposited on the PET substrate covered with the ITO transparent conductive layer. The parameters in the sputtering process are as follows: the sputtering method is radio frequency sputtering or intermediate frequency sputtering, and the working gas is O 2 and Ar, where O 2 The flow ratio of Ar and Ar is 0.2:4; the substrate temperature is 25°C; the vacuum degree is 0.1×10 -2 Pa; sputtering pressure value is 0.4Pa; sputtering power density is 2.8W / cm 2 ; The thickness of the tungsten oxide layer is 200nm;

[0091] (2) Magnetron sputtering deposition of amorphous ZnO buffer layer

[0092] The zinc-tin oxide target is placed in the magnetron sputtering coating equipment, and the amorphous zinc-tin oxide buffer layer is deposited on the ITO transparent conductiv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com