Superhard DLC cutter coating of amorphous gradient structure, preparation method of superhard DLC cutter coating and cutter

A gradient structure and gradient layer technology, which is applied in coating, metal material coating process, ion implantation plating, etc., can solve the problems that the strength of cemented carbide coating tools cannot meet the use requirements, and the price of diamond tools is expensive. Achieve good thermal stability and chemical stability, good thermal conductivity and hardness, and high film-base bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

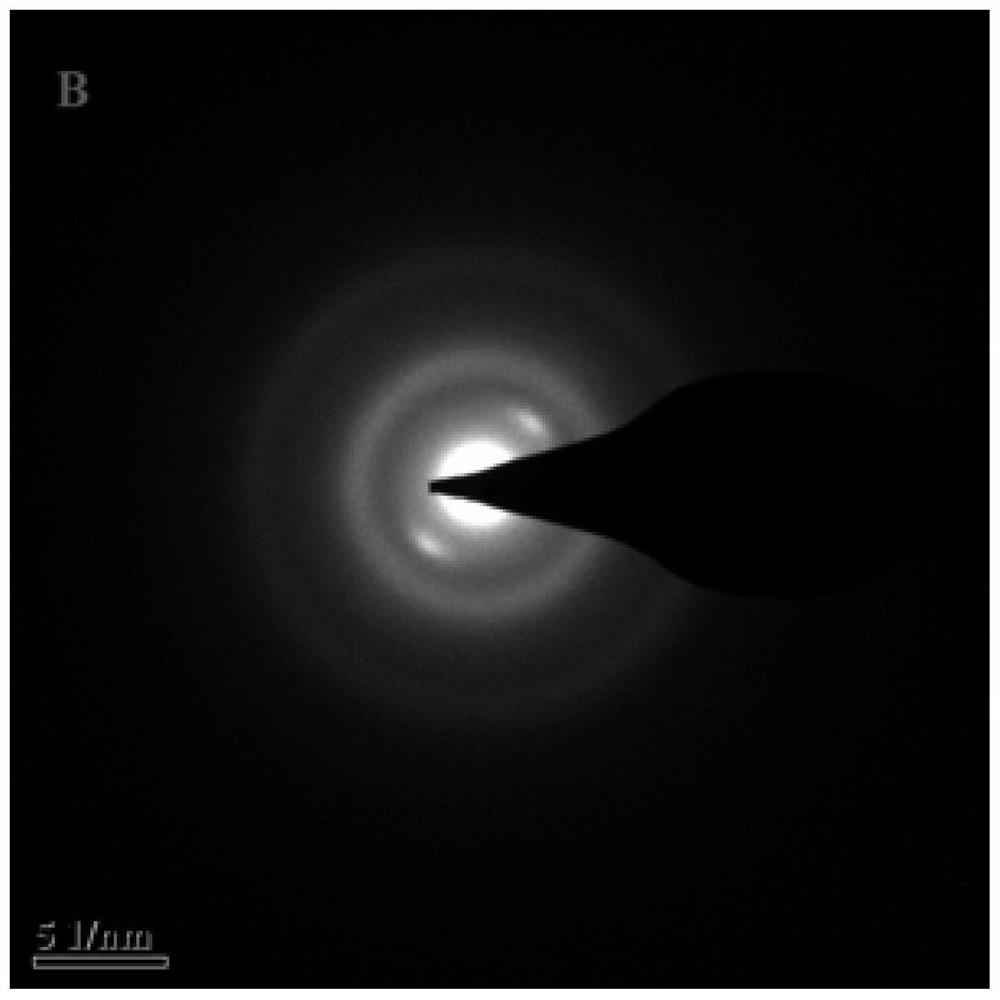

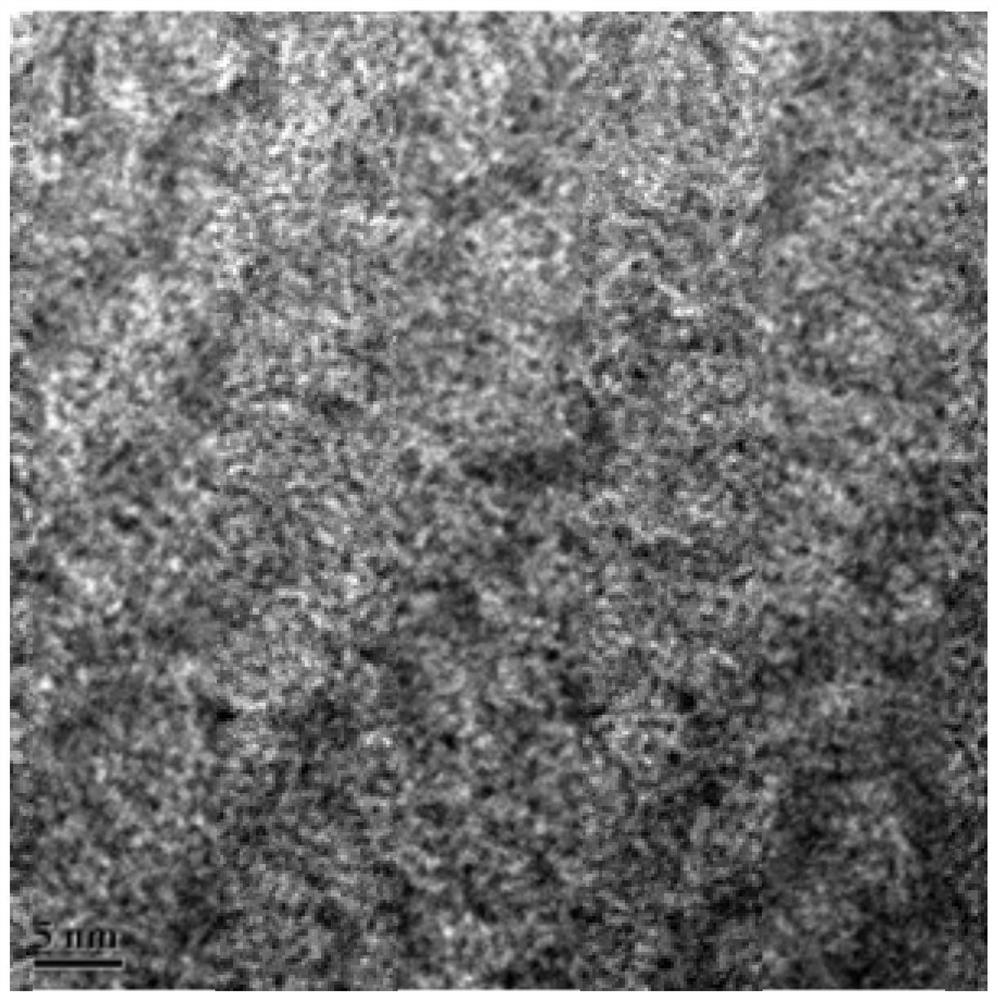

Embodiment 1

[0032] Embodiment 1: This embodiment provides a superhard DLC tool coating with an amorphous gradient structure, and a coating with a thickness of 2.5 μm is deposited on the collective tool by PVD deposition. The tool matrix composition is 92 parts of WC powder and 8 parts of Co. The coating consists of a pure Cr transition layer, a Cr / C transition layer, DLC (sp 3 gradient layer), the pure Cr transition layer is about 100nm thick, the Cr / C transition layer is about 200nm thick, and the DLC (sp3 gradient layer) is 2.2μm thick. The composition of the Cr / C transition layer is in parts by weight, from 100 parts of Cr to 50 parts, and from 0 parts of C to 50 parts. In the DLC, sp 3 The content is gradually reduced from 75 parts to 40 parts.

Embodiment 2

[0033] Embodiment 2: This embodiment provides an amorphous gradient structure superhard DLC tool coating, and a 2.08 μm thick coating is deposited on the tool collective by PVD deposition. The tool matrix is sintered from 92 parts of WC powder and 8 parts of Co. The coating consists of a pure Cr transition layer, a Cr / C transition layer, DLC (sp 3 Gradient layer), the pure Cr transition layer is about 150nm thick, the Cr / C transition layer is about 230nm thick, and the DLC (sp3 gradient layer) is 1.7μm thick. The composition of the Cr / C transition layer is by weight, changing from 100 parts to 50 parts of Cr, and increasing C from 0 parts to 50 parts, and the DLC (sp 3 gradient layer) by sp 3 The content gradually reduces the deposition composition from the transition layer to the surface, in parts by weight, in the DLC, sp 3Content gradually reduces to 48 parts of surface layer by 78 parts.

Embodiment 3

[0034] Embodiment 3: This embodiment provides an amorphous gradient structure superhard DLC tool coating, and a 2.7 μm thick coating is deposited on the tool collective by PVD deposition. The tool matrix is sintered from 92 parts of WC powder and 8 parts of Co. The coating consists of a pure Cr transition layer, a Cr / C transition layer, DLC (sp 3 Gradient layer) composition, the thickness of the pure Cr transition layer is about 100nm, the thickness of the Cr / C transition layer is about 200nm, and the thickness of DLC (sp3 gradient layer) is 2.4μm. The composition of the Cr / C transition layer is in parts by weight, from 100 parts of Cr to 50 parts, and from 0 parts of C to 50 parts. In the DLC, sp 3 The content is gradually reduced from 75 parts to 40 parts.

[0035] This invention also provides a preparation method of the superhard DLC tool coating with an amorphous gradient structure, which is carried out according to the following steps;

[0036] S1. Pretreatment: Sand...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com