Molding equipment for hot bending of glass

A molding equipment and glass technology, applied in glass molding, glass reshaping, glass manufacturing equipment, etc., can solve the problems of inconvenient, safe and efficient heating, and achieve the effects of reducing heat loss, avoiding uneven surface, and reducing mold damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

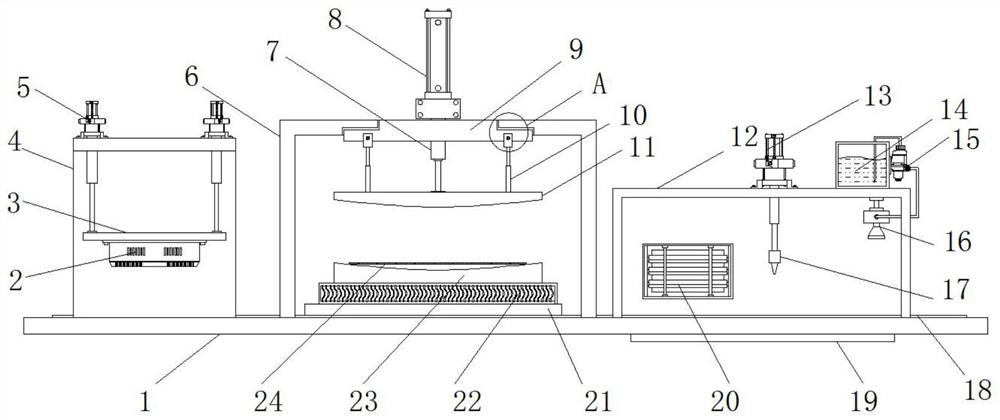

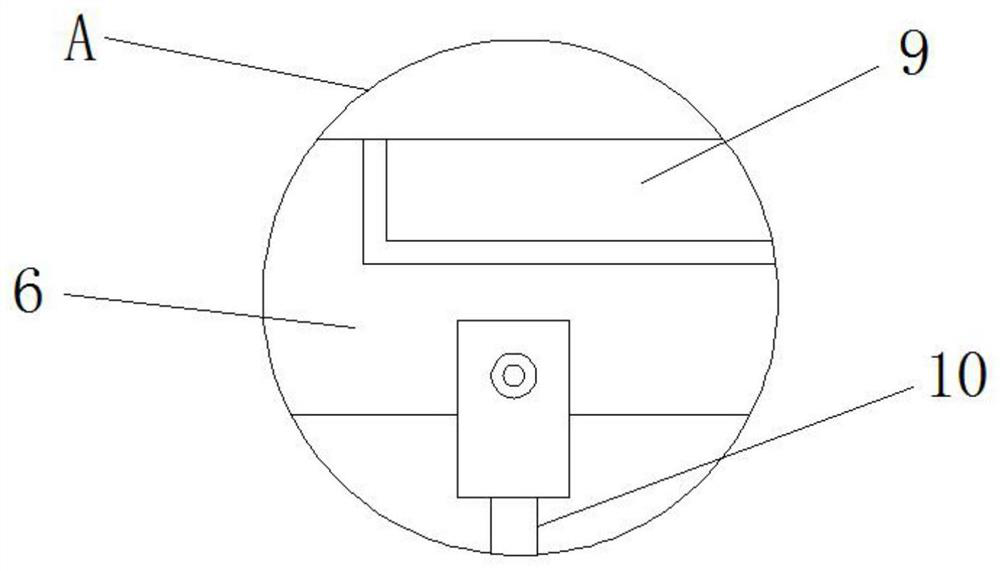

[0020] Example 1: See Figure 1-4 , a forming device for hot bending of glass, comprising a processing table 1 and a heating furnace 6, the top of the processing table 1 is provided with a heating furnace 6, one side of the heating furnace 6 is provided with a cooling table 4, and the other side of the heating furnace 6 The side is provided with a pretreatment chamber 12, the top of the heating furnace 6 is installed with a heat shield 9, the top of the heat shield 9 is fixedly connected with a hydraulic cylinder 8, the output end of the hydraulic cylinder 8 is provided with a hydraulic rod 7, and the hydraulic rod 7 extends to the heating The inside of the furnace 6 is fixedly connected with an upper mold base 11, and a telescopic rod 10 is fixedly connected between the two sides of the top of the upper mold base 11 and the heat shield 9, and the bottoms at both ends of the heating furnace 6 are provided with heating wires 22;

[0021] A conveyor belt 18 is installed on the t...

Embodiment 2

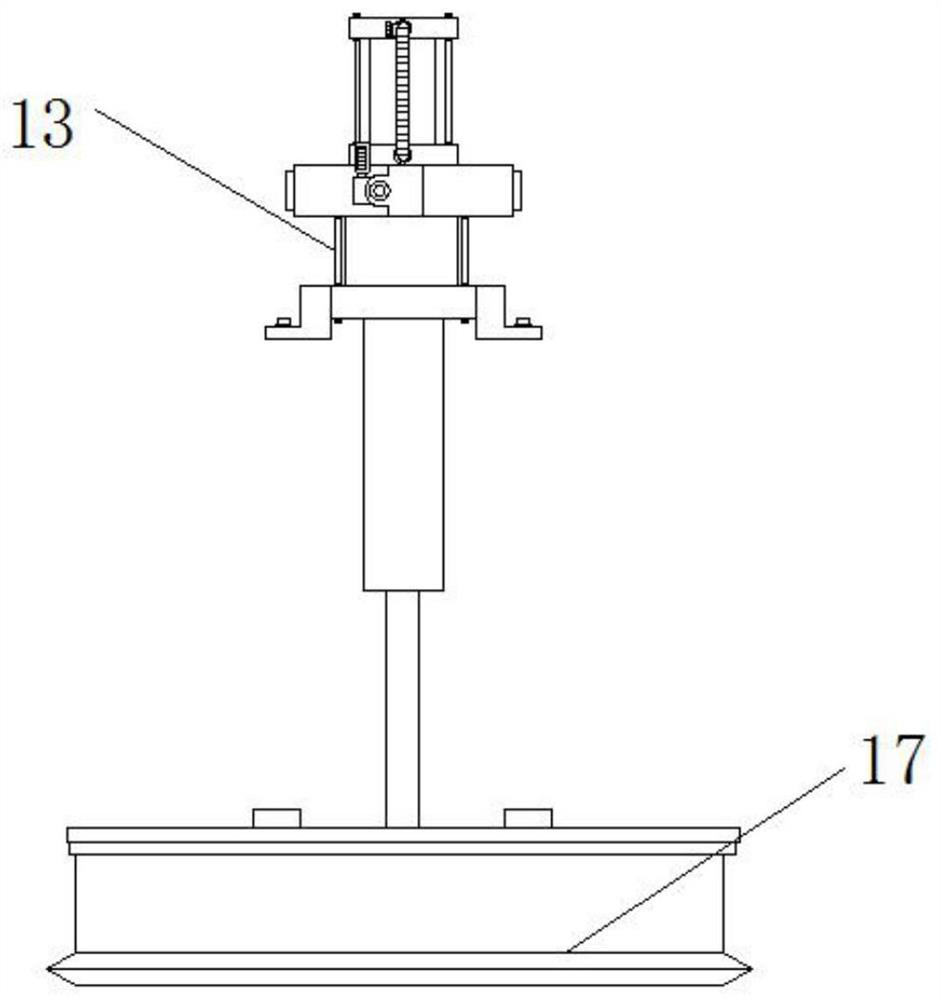

[0023] Embodiment 2: the top inside the pretreatment chamber 12 is fixedly connected with the first cylinder 13, the bottom end of the first cylinder 13 is fixedly connected with the scraper 17 through the piston rod, and the two ends of the inner wall of the pretreatment chamber 12 are all provided with heating copper pipes 20. A washing tank 14 is installed on the other side of the top of the pretreatment chamber 12, and a high-pressure pump 15 is installed on the outside of the washing tank 14, and a nozzle 16 is installed on the other side of the top inside the pretreatment chamber 12, and there are multiple groups of nozzles 16 and arranged at equal intervals, the nozzle 16 and the high-pressure pump 15 are connected through a water guide pipe, and a water collection tank 19 is arranged under the nozzle 16;

[0024] Specifically, such as figure 1 , figure 2 with Figure 4 As shown, before entering the heating furnace 6, the glass workpiece 24 first enters the pretreatm...

Embodiment 3

[0025] Embodiment 3: Two sets of second cylinders 5 are fixedly connected to the top of the cooling table 4, and the output ends of the second cylinders 5 are fixedly connected to a fixed frame 3 through a piston rod, and an air cooler 2 is installed at the bottom of the fixed frame 3;

[0026] Specifically, such as figure 1 As shown, after the glass workpiece 24 is heated in the heating furnace 6, it arrives at the cooling table 4, and the second cylinder 5 drives the air cooler 2 at the bottom of the fixed frame 3 to lift up and down through the piston rod, thereby adjusting the surface of the air cooler 2 and the glass workpiece 24. The distance is suitable for cooling glass with different curvatures. The initial distance between the air cooler 2 and the glass workpiece 24 is relatively small. As it continues to drop, the wind speed is adjusted to the maximum to gradually cool the glass surface, thereby avoiding overheating. Move, reduce damage to the mold, improve the effi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com