Method for processing metallic chain link fence hanging net for marine anti-pollution tests and method for tying same

An experimental, orthorhombic net technology, which is applied in applications, fish farming, climate change adaptation, etc., can solve problems such as iron frame corrosion, and achieve the effects of preventing loss, saving time, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

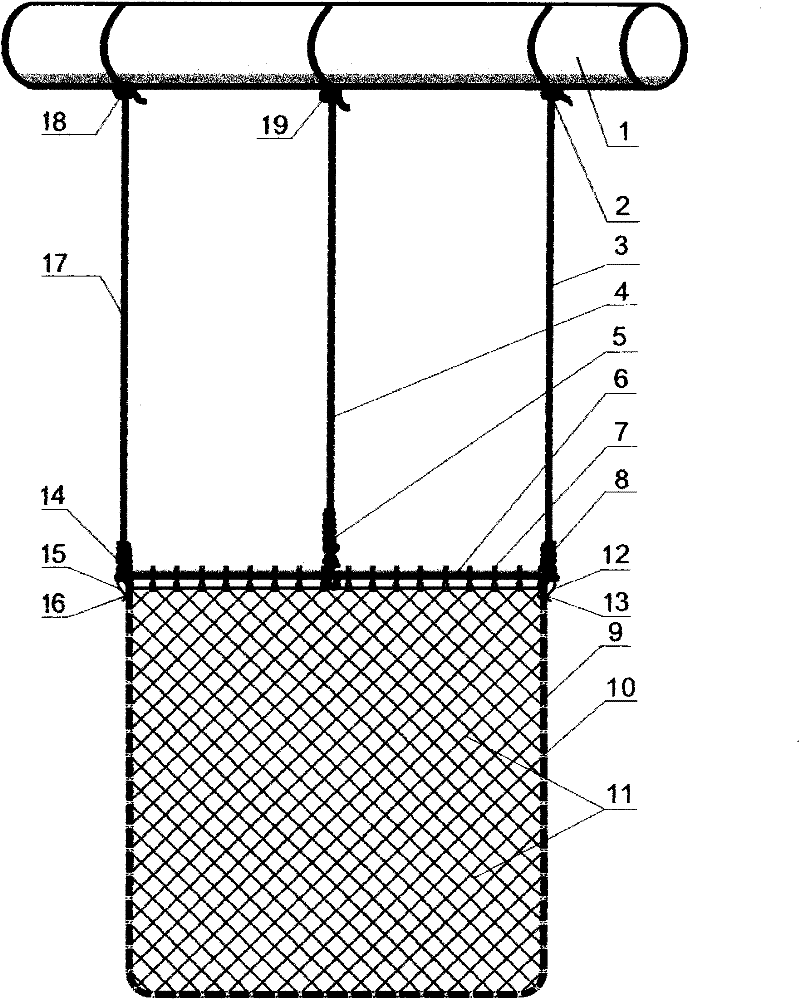

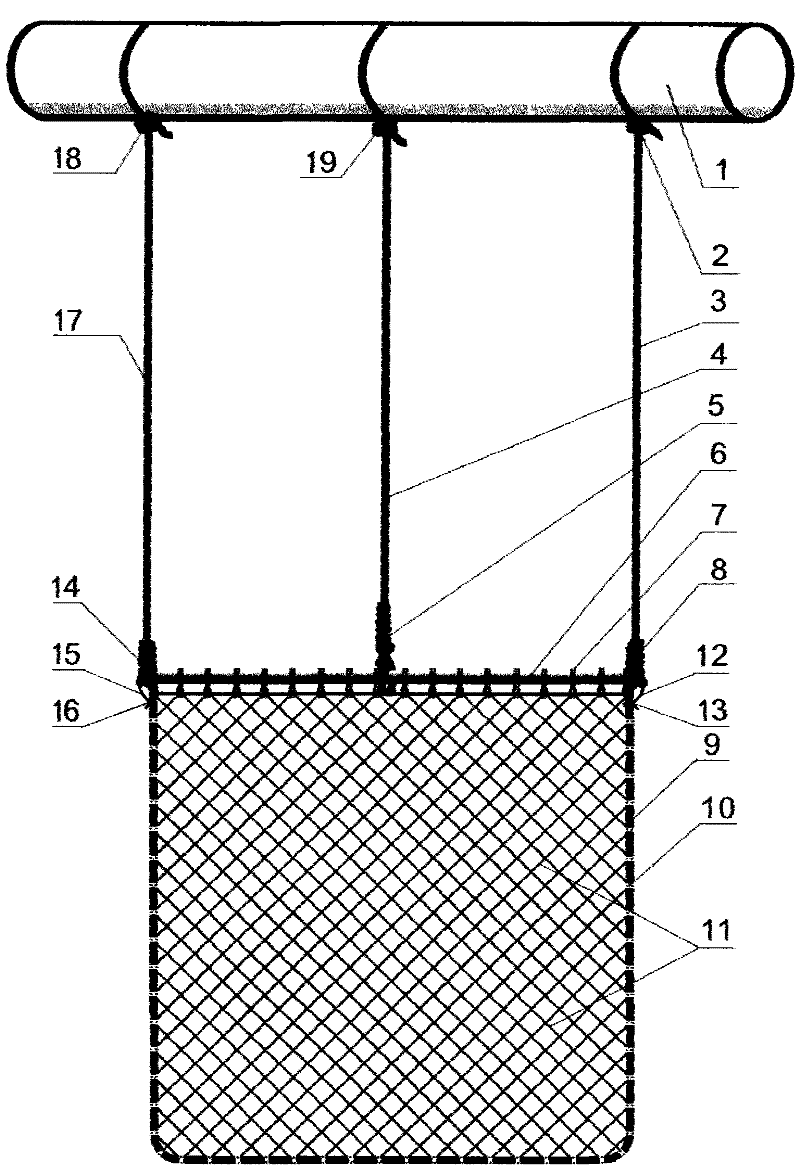

[0007] The best way to implement the present invention is illustrated below in conjunction with the accompanying drawings:

[0008] The present invention adopts PPR pipes, ropes and metal trapezoidal nets, and the metal trapezoidal nets are cut vertically and horizontally to obtain a square metal trapezoidal net with a specification of 0.53m×0.53m, and the mesh shrinkage coefficient corresponding to this specification is 0.707; The square metal orthorhombic mesh with a side length of 0.53m and a peripheral width of 0.03m are bent and processed to prevent the metal wires from falling or shifting for the metal orthorhombic mesh, so as to obtain a piece of The specification is 0.50m×0.50m square metal orthorhombic mesh, under which the corresponding mesh shrinkage coefficient is 0.707; wires 9 are installed around the 0.50m×0.50m square metal orthorhombic mesh 11, and the diameter of the wires is 14mm high-strength three-strand polyethylene rope for fishing, and the suture thread...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com