Method for manufacturing and hanging suspending net for sea trial of antifouling paint of netting cage covering

An anti-fouling paint, sea test technology, applied in application, fish farming, climate change adaptation and other directions, can solve the problems of random influence on cage nets, test failure, influence on the stability of hanging nets, etc., to avoid anti-fouling function. Interact, save valuable time, and ensure the effect of a successful trial

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

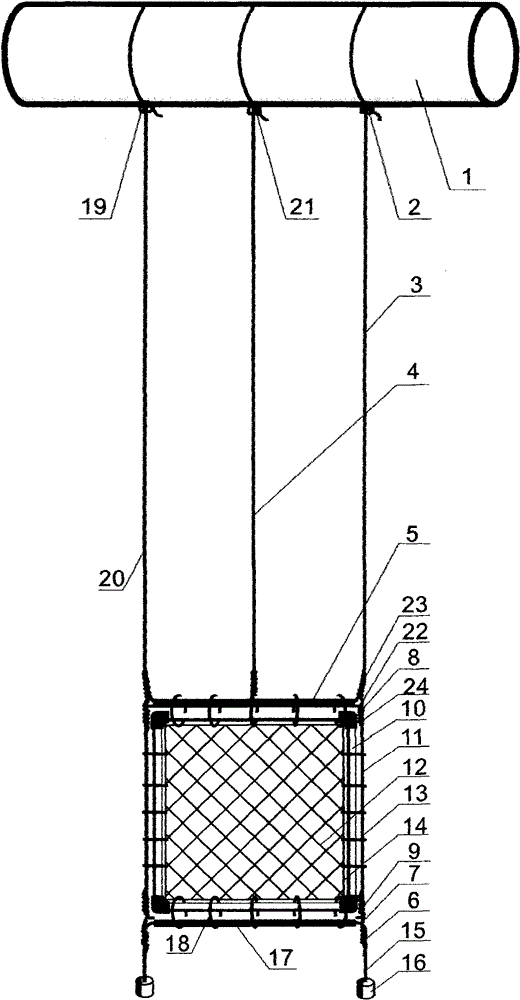

[0007]The best mode of the present invention (see accompanying drawing): adopt PPR pipe, rope, net clothing and stone, be processed into the square PPR frame 10 that specification is 0.5m * 0.5m with diameter 20mmPPR pipe, 4 bendings of square PPR frame All are connected with 90° angled joints 8; a rope frame 11 is installed around the outside of the square PPR frame pipe wall, the rope frame is made of three strands of high-strength fishing polyethylene rope with a diameter of 8mm, and two lengths 0.5m, 25mm diameter PPR pipe, two PPR pipes 5 and 17 with a diameter of 25mm are respectively placed outside the upper and lower sides of the square PPR frame; between the left rope frame and the left side of the square PPR frame, and between the right rope frame and the Three strands of high-strength polyethylene ropes 13 for fishing with a diameter of 4mm are used to bind between the right sides of the square PPR frame, and three strands of diameter 4mm are also used between the tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com