Method for manufacturing and suspending anti-polluting test hanging net of metal woven net for net box

A metal woven net and cage technology, applied in the field of fishery engineering, can solve the problems of incomparable antifouling effect of hanging nets, delaying the best test time, and failure of the test, so as to avoid mutual influence of antifouling functions, Save raw material consumption and ensure the effect of successful test

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

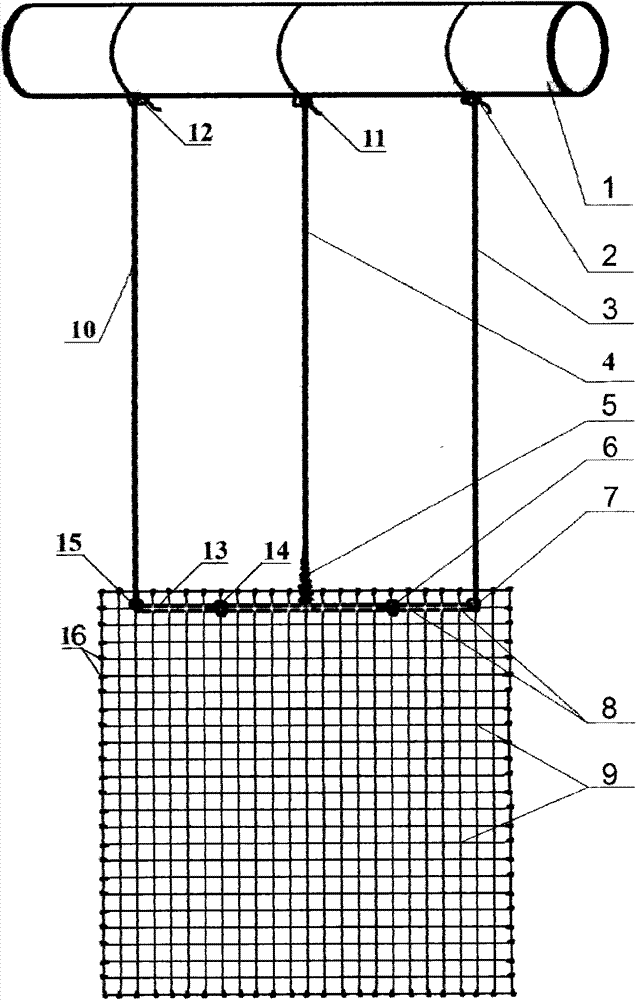

[0007] The best mode of implementing the present invention (referring to accompanying drawing): adopt rope and metal braided net, be that the square metal braided net of 0.54m * 0.54m is obtained by longitudinal cutting and transverse cutting by the metal braided net of marine antifouling test; This side length is 0.54m the square metal braided mesh peripheral width is that the mesh in the area of 0.04m and the cut mesh foot end 16 are carried out bending processing, to prevent the shedding or displacement of the metal wire for the metal braided mesh, thereby obtaining The specification is 0.50m×0.50m square metal braided mesh 9; on the upper side of the 0.50m×0.50m square metal braided mesh, a 0.4m long wire rope 13 is installed at a distance from the upper side edge of the mesh sheet, and the wire rope adopts a high-strength wire mesh with a diameter of 16mm. The three-strand polyethylene rope for fishing, the suture thread used for binding the metal braided net and the cab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com