Method for processing and suspending maritime anti-fouling test hanging net of metal stretched net

A stretched net and experimental technology, applied in application, fish farming, climate change adaptation, etc., can solve the problems of incomparable antifouling effect of hanging nets, increasing raw material consumption, affecting the stability of hanging nets, etc. Achieving the effect of avoiding the mutual influence of antifouling functions, saving valuable time and ensuring the success of the test

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

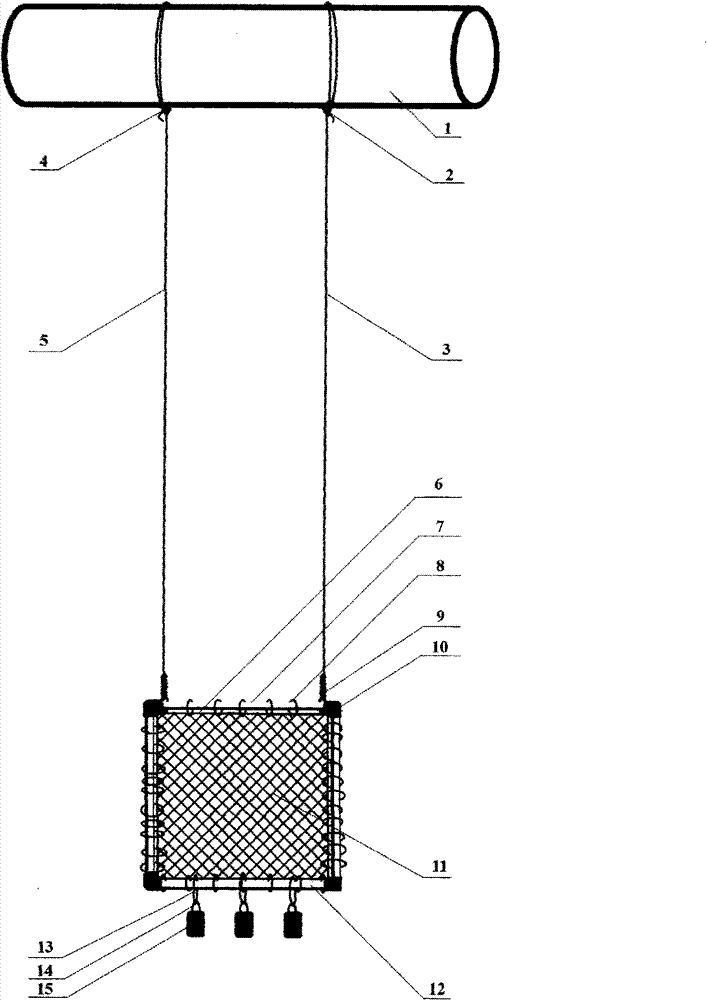

[0007] The best mode of implementing the present invention (see accompanying drawing) is to adopt the PPR pipe of diameter 25mm and the stretched metal net, process the PPR pipe of diameter 25mm into the square framework that specification is 0.5m * 0.5m with hot melting machine, square framework The 4 bends are all connected by 90° angled joints 10, thus obtaining the hanging net frame 7 for the marine anti-fouling test of the stretched metal net. Cut out a square metal stretched mesh with a size of 0.52m×0.52m, and then bend the mesh and the end of the cut mesh foot in the area of the square stretched metal mesh with a side length of 0.52m and a peripheral width of 0.02m. , to obtain a piece of specification is 0.50m × 0.50m square metal stretched net; tie the edge net 6 around the perimeter of the 0.50m × 0.50m square metal stretched net, and the side net adopts a high-strength fishing three-strand polyethylene rope with a diameter of 16mm. The sutures used for binding th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com