Composite acidifier as well as preparation method and application thereof

A technology of compound acidifier and sugar acid, applied in application, animal feed, additional food elements, etc., can solve the problem of inappropriate liquid acidifier, etc., to reduce irritation and corrosiveness, less irritation, and better use effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

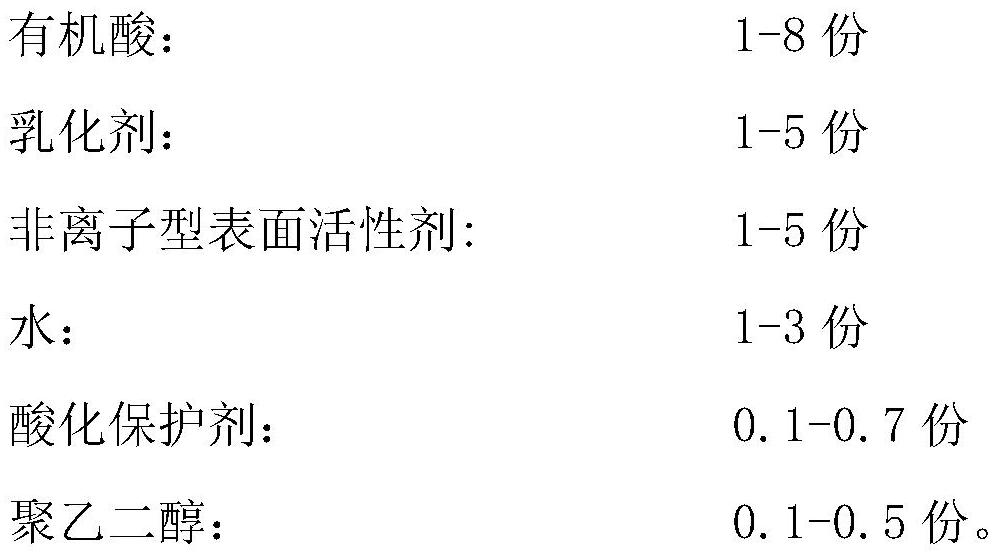

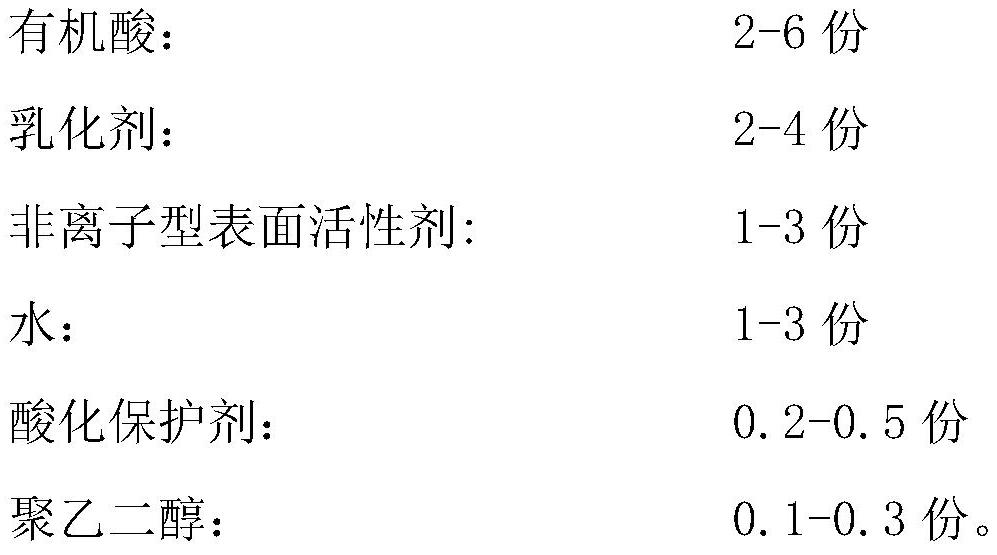

[0044] A kind of composite acidulant, by parts by weight, comprising:

[0045] Organic acid mixture (lactic acid, formic acid, acetic acid = 3:1:1): 5 parts

[0046] Propylene glycol: 3 parts

[0047] Span 80:1 serving

[0048] Water: 1 part

[0049] Polyvinylpyrrolidone k17: 0.3 parts

[0050] Polyethylene glycol 6000: 0.1 parts

[0051] After adding polyvinylpyrrolidone k17 and PEG 6000 into water to dissolve completely, add the solution into propylene glycol and stir evenly, add Span 80 and organic acid mixture at one time, cut at 7500rpm for 2min, and pass through a homogenizer at 400bar to obtain a uniform emulsion.

Embodiment 2

[0053] A kind of composite acidulant, by parts by weight, comprising:

[0054] Organic acid mixture (lactic acid, acetic acid, propionic acid = 3:1:1): 5 parts

[0055] Propylene glycol: 3 parts

[0056] Span 80:1 serving

[0057] Water: 3 parts

[0058] Polyvinylpyrrolidone k30: 0.3 parts

[0059] Polyethylene glycol 6000: 0.1 parts

[0060] After adding polyvinylpyrrolidone k30 and PEG 6000 into water to dissolve completely, add the solution into propylene glycol and stir evenly, add Span 80 and organic acid mixture at one time, cut at 10000rpm for 2min, and pass through a homogenizer at 300bar to obtain a uniform emulsion.

Embodiment 3

[0062] A kind of composite acidulant, by parts by weight, comprising:

[0063] Organic acid mixture (lactic acid, formic acid, propionic acid, citric acid = 3:1:1:0.5): 5 parts

[0064] Propylene glycol: 3 parts

[0065] Span 80: 2 servings

[0066] Water: 2 parts

[0067] Polyvinylpyrrolidone k30: 0.4 parts

[0068] Polyethylene glycol 8000: 0.2 parts

[0069] After adding polyvinylpyrrolidone k30 and PEG8000 into water to dissolve completely, add the solution to propylene glycol and stir evenly, add Span 80 and the above-mentioned organic acid mixture at one time, cut at 5000rpm for 7min, and pass through a homogenizer at 350bar to obtain a uniform emulsion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com