Transition metal phosphide composite material for oxygen evolution of acidic electrolysis water and preparation method thereof

A technology for acid electrolysis of water and transition metals, applied in the electrolysis process, electrolysis components, electrodes, etc., can solve the problems of high price, low activity and poor stability of acid electrolysis water oxygen evolution catalyst, and achieve excellent electrolysis water oxygen evolution catalytic activity. , easy to combine, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

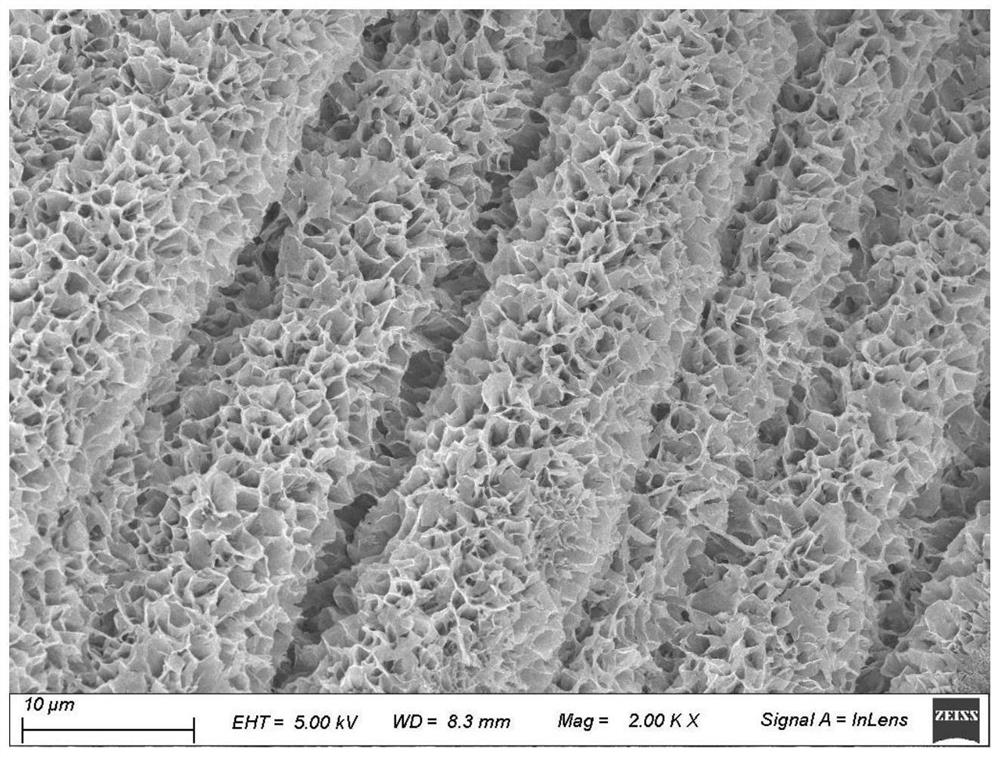

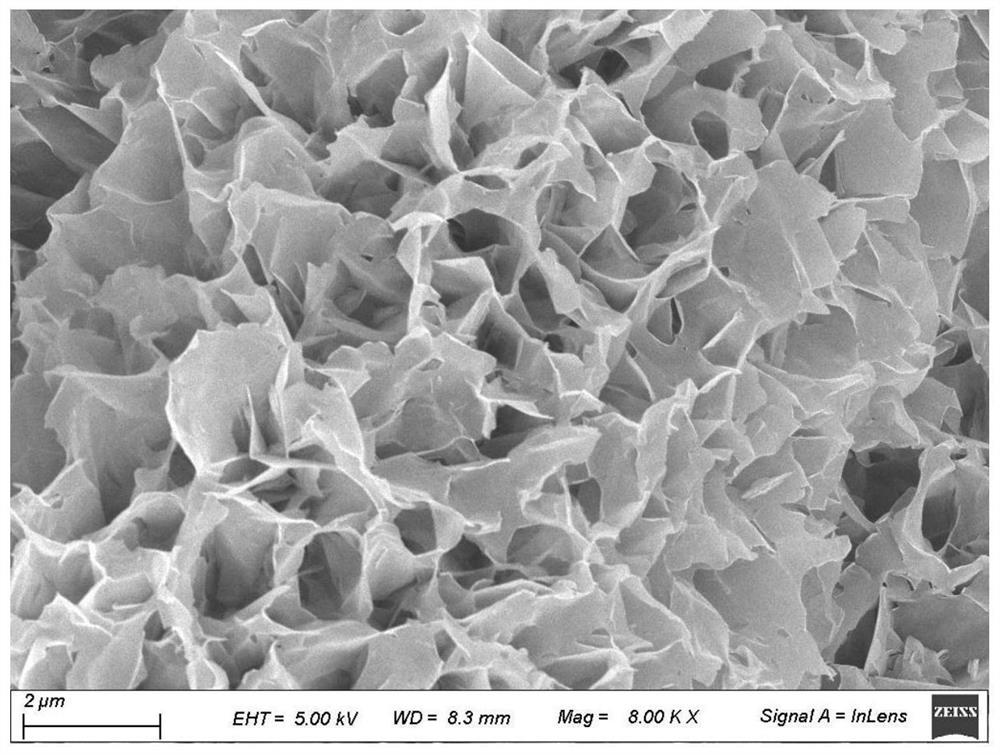

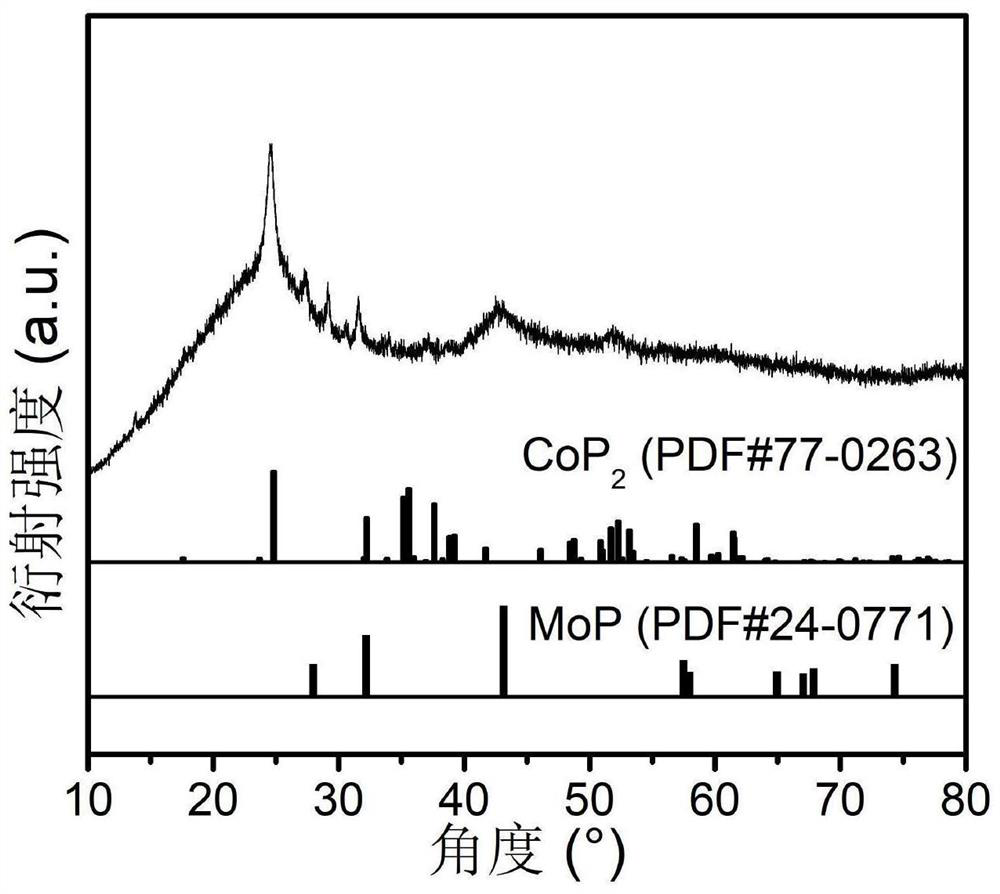

[0032] Embodiment 1: The preparation method of the transition metal phosphide complex in this embodiment is realized according to the following steps:

[0033] Step 1: Cut the carbon cloth into a small cube with a size of 3cm×3cm, and then place it in a mixed solution of concentrated hydrochloric acid with a mass fraction of 36% and concentrated sulfuric acid with a mass fraction of 98.3% for ultrasonic cleaning for 30 minutes, and then let the acid stand Treat for 4 hours, then wash with distilled water again, place in an oven and dry at 60°C for 4 hours to obtain a pretreated carbon cloth; the volume ratio of concentrated hydrochloric acid and concentrated sulfuric acid in the mixed solution is 1:3.

[0034] Step 2, dissolving 0.3g of cobalt nitrate and 0.2g of phosphomolybdic acid in 25mL of distilled water, stirring evenly, the color of the solution turns brown, forming a cobalt-molybdenum polyacid cluster intermediate;

[0035] Step 3, transfer the reaction solution obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com