Preparation and application of polyurea extinction microspheres with light scattering characteristic

A technology of light scattering and characteristics, applied in the direction of polyurea/polyurethane coatings, coatings, etc., to meet the needs of extinction, improve dispersion stability, and improve compatibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

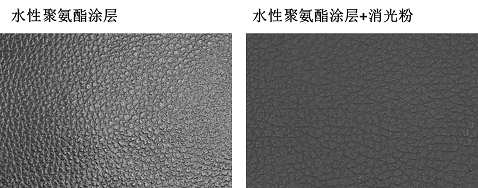

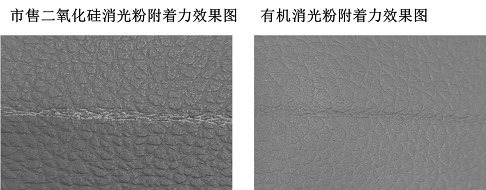

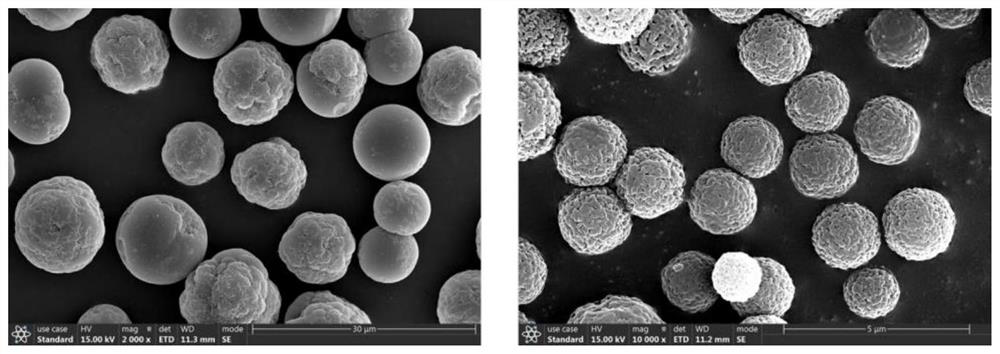

[0024] Preparation and application of organic matting microspheres with light scattering properties: 100 parts of acetonitrile / water mixed solvent with a ratio of 70 / 30, 8 parts of isophorone diisocyanate, 2,4-diaminobenzenesulfonic acid 0.6 parts of sodium, mixed evenly to obtain a dispersed phase. Slowly raise the temperature to 50°C by means of static reaction, then take 4 parts of nano silicon dioxide and add it into the reaction kettle when the reaction system starts to become cloudy, mix evenly, and react for 4 hours. After centrifugation, pour off the upper layer, wash with distilled water, and centrifuge again, repeat this operation 5 times, and dry in an oven at 80 °C to obtain powdery polyurea matting microspheres with light scattering properties.

[0025] The organic extinction microspheres with light scattering characteristics prepared by the above method have a yield of 83.6%. The surface has a special groove structure, which has a scattering effect on incident li...

Embodiment 2

[0027] Preparation of organic matting microspheres with light scattering properties: 100 parts of acetonitrile / water mixed solvent with a ratio of 60 / 40, 1 part of hexamethylene diisocyanate, 0.14 parts of sodium ethylenediaminoethanesulfonate were added to the reaction kettle, Mix well to obtain a dispersed phase. Slowly raise the temperature to 60°C by constant temperature oscillation reaction, then take 0.1 part of polyvinylpyrrolidone (PVP) and add it into the reactor at the beginning of the reaction, mix it evenly, and react for 5 hours. After centrifugation, pouring off the upper layer, washing with distilled water, and centrifugation again, this operation was repeated 5 times, and dried in an oven at 100°C to obtain powdery polyurea matting microspheres with light scattering properties.

[0028] The organic extinction microspheres with light scattering characteristics prepared by the above method have a yield of 72.5%. The surface has a special groove structure, which h...

Embodiment 3

[0030] Preparation of organic matting microspheres with light scattering properties: add 100 parts of acetonitrile / water mixed solvent with a ratio of 80 / 20, 6 parts of dicyclohexylmethane diisocyanate, and 0.3 part of dimethylol propionic acid into the reaction kettle, and mix well to obtain a dispersed phase. Slowly raise the temperature to 40° C. by mechanical stirring, then take 0.6 parts of nano-calcium carbonate and add it into the reactor at the beginning of the reaction, mix evenly, and react for 6 hours. After centrifugation, pour off the upper layer, wash with distilled water, and centrifuge again, repeat this operation 5 times, and dry in an oven at 100 °C to obtain powdery polyurea matting microspheres with light scattering properties.

[0031] The organic extinction microspheres with light scattering characteristics prepared by the above method have a yield of 79.6%. The surface has a special groove structure, which has a scattering effect on incident light. The a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com