Starch-based capsule coat as well as preparation method and application thereof

A starch-based, capsule-based technology, which is applied in application, capsule delivery, and pharmaceutical formulations, can solve problems such as poor use effect, difficult processing and molding, and poor plasticity of starch.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The present invention also provides the preparation method of the starch-based capsule coat described in the above technical scheme, comprising the following steps:

[0034] (1) mixing anion / cation starch, natural product and water to obtain an initial mixture;

[0035] (2) Melting and extruding the initial mixture obtained in the step (1) to obtain a semi-finished product;

[0036] (3) The semi-finished product obtained in the step (2) is subjected to thermocompression molding or blister molding to obtain a starch-based capsule coat;

[0037] When the raw material of the starch-based capsule coat includes a plasticizer, the plasticizer is added in step (1).

[0038] The invention mixes anion / cation starch, natural product and water to obtain primary mixture.

[0039] In the present invention, the operation of mixing the anion / cation starch, natural products and water is preferably mixed in a high-speed mixer; the mixing speed is preferably 100-2000rpm, more preferabl...

Embodiment 1

[0050] The starch-based capsule coat is prepared from the raw materials in the following mass percentages:

[0051] Carboxymethyl starch 50wt%, chitosan 30wt%, plasticizer glycerin 10wt% and the water of remainder;

[0052] The preparation method of described starch-based capsule coat, is the following steps:

[0053] (1) Carboxymethyl starch, chitosan, glycerin and water are placed in the high-speed mixer according to the corresponding proportion, and are preliminarily blended for 5 minutes at a speed of 500 rpm to obtain the initial mixture;

[0054] (2) Add the primary mixture obtained in the step (1) to a twin-screw extruder at a feed rate of 25rpm for melt extrusion. The temperatures in each zone of the extruder are respectively: 40°C in the first zone and 80°C in the second zone. ℃, 120°C in the third zone, 120°C in the fourth zone, 120°C in the fifth zone, 100°C in the sixth zone, 80°C in the seventh zone, 80°C in the die head, and the screw speed is 150rpm, and a 0.15...

Embodiment 2

[0057] The starch-based capsule coat is prepared from the raw materials in the following mass percentages:

[0058] Starch succinate 65wt%, polylysine 20wt%, plasticizer polyethylene glycol 3wt% and the water of remainder;

[0059] The preparation method of described starch-based capsule coat, is the following steps:

[0060] (1) Starch succinate, polylysine, polyethylene glycol and water are placed in a high-speed mixer in corresponding proportions, and initially blended at a speed of 1000 rpm for 3 minutes to obtain an initial mixture;

[0061] (2) Add the primary mixture obtained in the step (1) to a twin-screw extruder at a feed rate of 30rpm for melt extrusion. The temperatures in each zone of the extruder are respectively: 40°C in the first zone and 80°C in the second zone. ℃, 150℃ in the third zone, 120℃ in the fourth zone, 120℃ in the fifth zone, 100℃ in the sixth zone, 90℃ in the seventh zone, 90℃ in the die head, and the screw speed is 200rpm, and a 0.1mm thick shee...

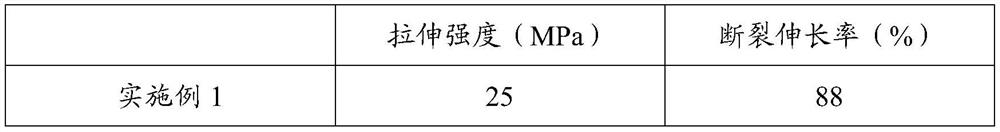

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com