Condensation type heat pump

A condensing and heat pump technology, applied in the direction of heat transfer modification, fluid heater, heat exchange equipment, etc., can solve the problems that affect the heat exchange efficiency of the heat exchanger, cannot guarantee the thickness of the coating, and the cumbersome manufacturing process, etc., to prevent Scale accumulation, ensuring stability, and improving heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

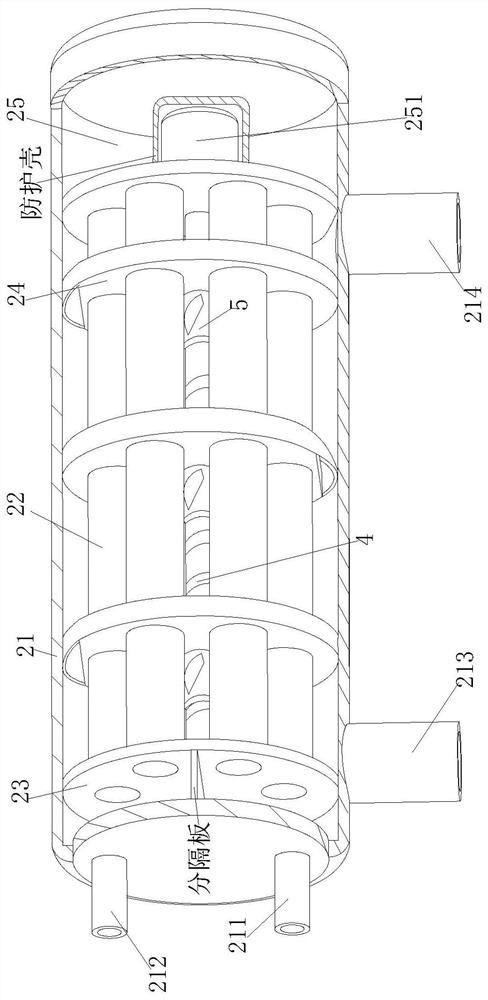

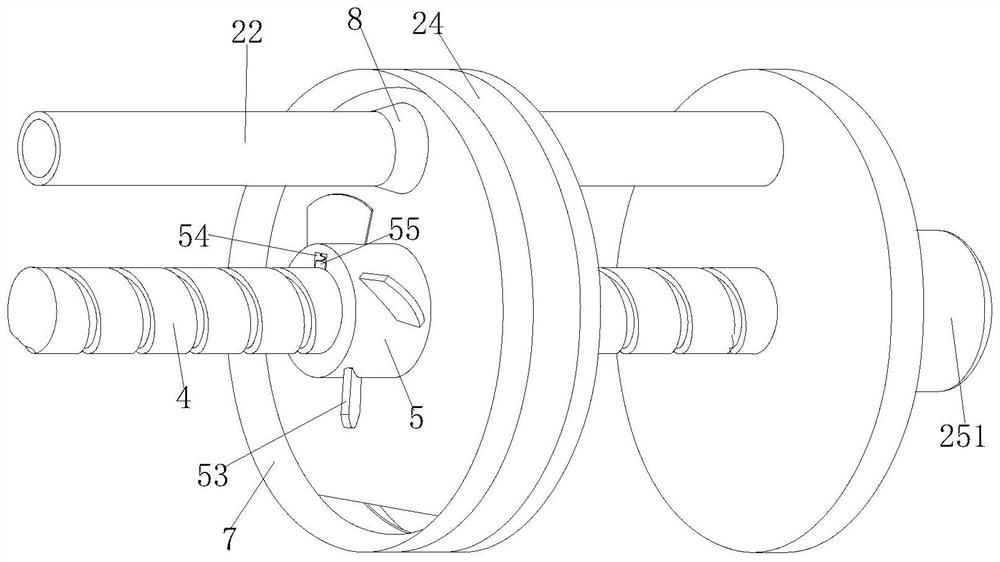

[0041] As an embodiment of the present invention, a cleaning groove 54 is provided on the inner side wall of the rotating sleeve 5; 55; the material of the cleaning block 55 is a flexible material;

[0042] During work, the worm screw 4 drives the baffle plate 24 to move, so that the worm screw 4 rotates relative to the inner wall of the rotating sleeve 5, and then the cleaning block 55 can brush the surface of the worm screw 4, so that the cleaning block 55 cleans up the scale on the worm screw 4 surface; When the baffle 24 moved together with the rotating sleeve 5, the cleaning block 55 also moved together with the baffle 24, and then the cleaning blocks 55 on all the rotating sleeves 5 could clean up the surface of the whole worm 4 to prevent the surface of the worm 4 from The scale affects the transmission between the worm 4 and the baffle 24, thereby affecting the movement of the baffle 24;

[0043] In the present invention, the worm 4 rotates relative to the inner wall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com