Device for recycling waste heat of flue gas in power station boiler

A technology for flue gas waste heat and power station boilers, which can be used in cleaning heat transfer devices, preheating, liquid degassing, etc., and can solve problems such as heat waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

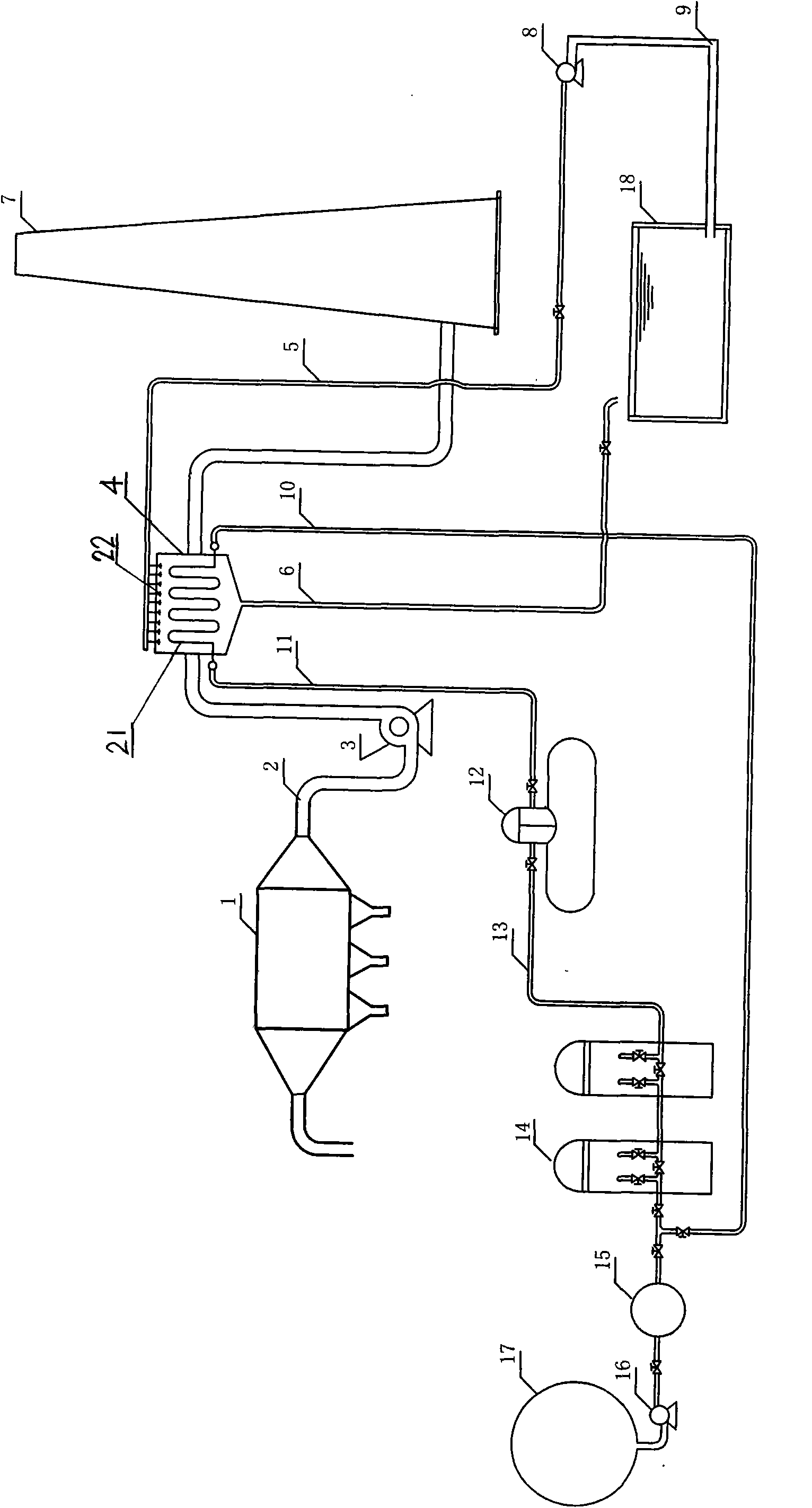

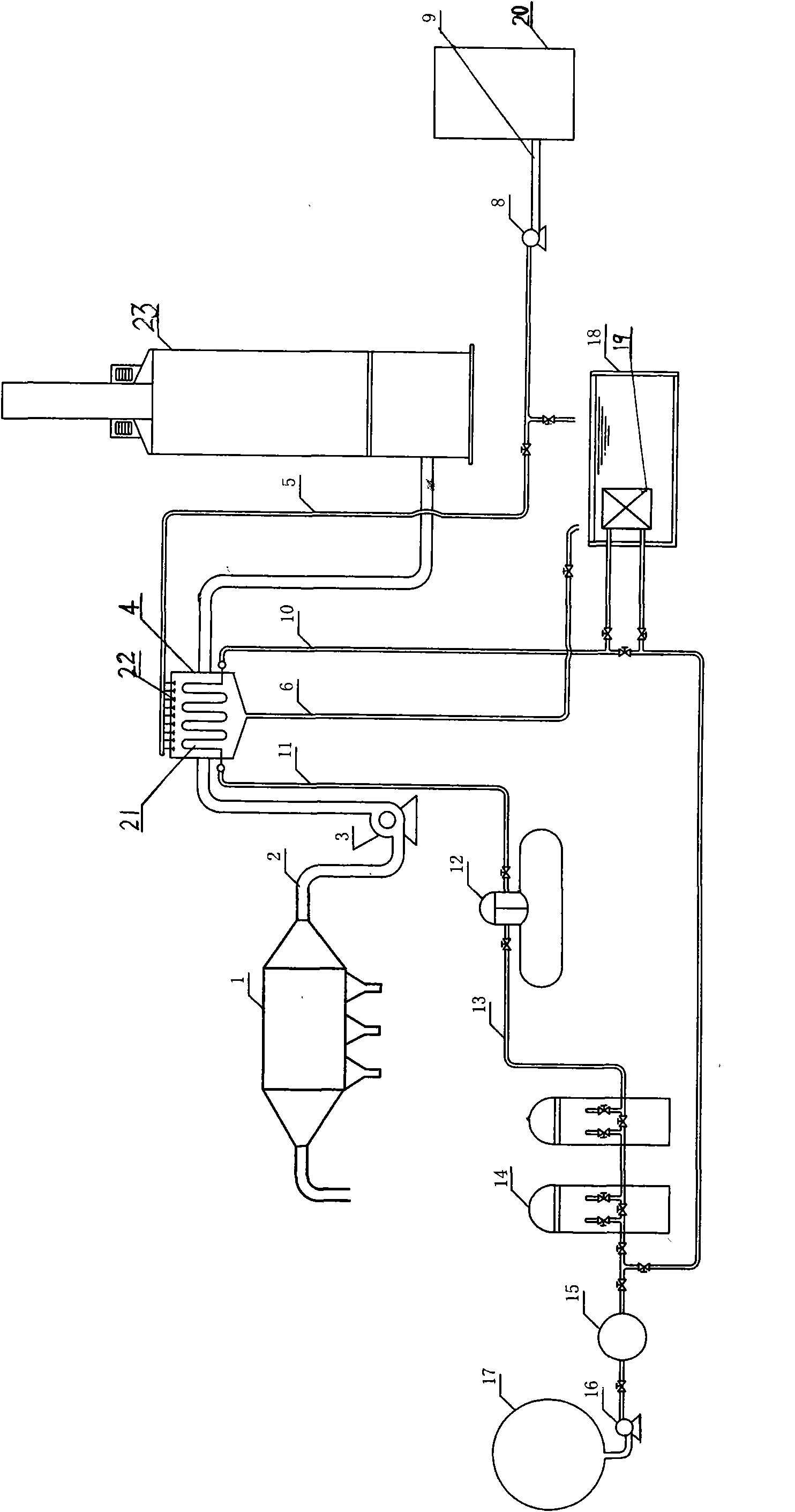

[0009] The specific structure of the present invention is illustrated below in conjunction with the embodiment given with accompanying drawing.

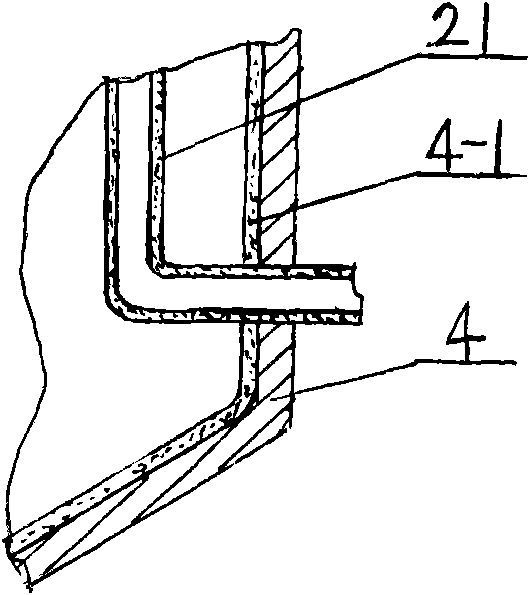

[0010] As shown in the figure, the utility boiler flue gas waste heat utilization device of the present invention has a heat exchanger inlet pipe 10, one end of which is connected to the pipeline between the shaft seal heater 15 and the low-pressure heater 14, and the other end is connected to the heat exchanger 4 The inner serpentine pipe 21 is connected, the other end of the serpentine pipe is connected with the deaerator 12 through the return pipe 11 of the heat exchanger, the deaerator is connected with the low-pressure heater 14 through the pipeline 13, and the bottom of the heat exchanger 4 is connected with cleaning water The return pipe 6 and the nozzle 22 on the upper part of the heat exchanger 4 are connected to one end of the cleaning water pipe 5, and the other end of the cleaning water pipe is connected to the sump 18 or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com