Assembly type lateral constraint limited slip steel plate shear wall and manufacturing method thereof

A steel plate shear wall and lateral restraint technology, applied in the direction of walls, protective buildings/shelters, building components, etc. The buckling steel plate shear wall is not easy to assemble, and the plastic deformation loses energy dissipation, so as to facilitate processing and transportation, avoid uneven buckling, and improve structural safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

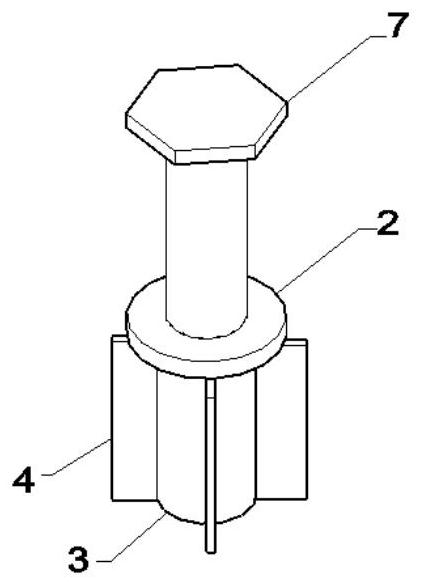

[0035] As shown in the figure, an assembled lateral restraint limited slip steel plate shear wall includes a steel plate shear wall 1, a drum node, a constraint member 5, a limiter 6, a connecting bolt 7 and a positioner 8, and the drum The nodes include the drum cover 2, the drum tube 3 and the drum ribs 4. The drum nodes are arranged on the wall surface of the steel plate shear wall 1 according to the energy dissipation requirements. The drum nodes are connected with the restraint members 5, and the restraint members 5 form an orthogonal square or oblique The restraint grid is placed obliquely, and the spacing of the restraint members 5 is determined according to the lateral buckling of the steel plate shear wall 1, so the drum nodes can be set at equal or non-equal intervals; the drum ribs 4 are used to connect the restraint members 5, and the drum The cover 2 is provided with a bolt hole through which the connecting bolt 7 connects the steel plate shear wall 1 with it.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com