Process for manufacturing high-dispersity multi-element nano inorganic metal oxide single-phase crystal structure through one-step thermal reaction

A technology with high dispersibility and process technology, applied in the field of synthesizing high dispersity nanometer solid solution oxide preparation, can solve problems such as increasing the production cost of nanometer oxide, and achieve the effect of large surface area, small particle size, and improved combustion reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

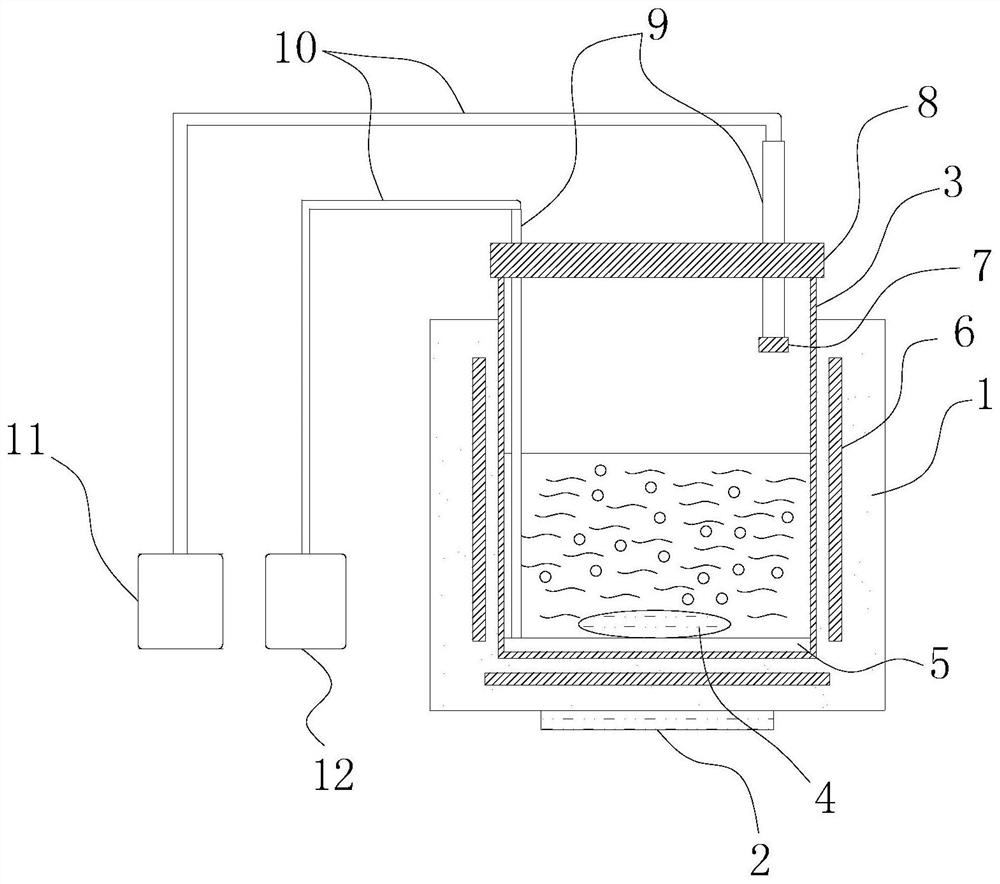

Method used

Image

Examples

Embodiment 1

[0066] A process technology for one-step thermal reaction and highly dispersed multi-component nano-inorganic metal oxide single-phase crystal structure, comprising the following steps:

[0067] (1) Set Y(NO 3 ) 3 , ZrO(NO 3 ) 2 To configure 20mmole 8YSZ (8mol%Y 2 o 3 stabilized ZrO 2 ) for chemical dosage, dissolve it in 50mL deionized water, add a citric acid clamping agent with 1.5 times the total molar number of metal ions, and keep stirring. For example, add 5 mL of nitric acid to the solution one by one until the metal compound is completely dissolved. In this example, 10mL of 16mol / L concentrated nitric acid was used and heated at 80°C to dissolve to obtain an aqueous solution;

[0068] (2) Add a glycine combustion agent with 1.5 times the total molar number of metal ions in the above aqueous solution, stir until dissolved, and obtain a reaction solution;

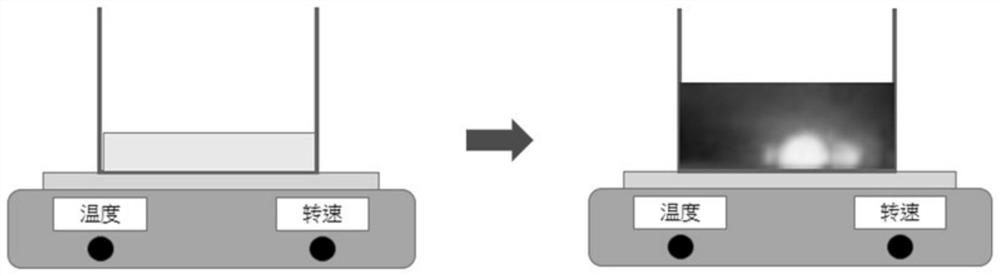

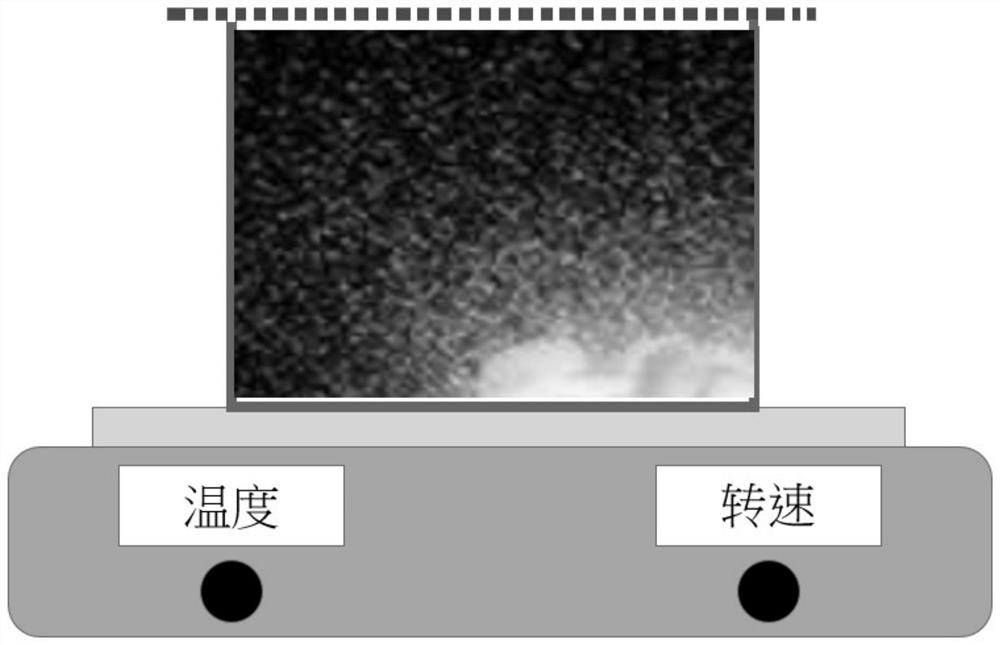

[0069] (3) Pour the reaction solution into the combustion reaction vessel in the above-mentioned reaction...

Embodiment 2

[0073] A process technology for one-step thermal reaction and highly dispersed multi-component nano-inorganic metal oxide single-phase crystal structure, comprising the following steps:

[0074] (1) Set Y(NO 3 ) 3 , ZrO(NO 3 ) 2 To configure 20mmole 8YSZ (8mol%Y 2 o 3 stabilized ZrO 2 ) for chemical dosage, dissolved in 50mL deionized water, added citric acid clamping agent with 1.5 times the total molar number of metal ions, and continued to stir. For example, add 5 mL of nitric acid to the solution one by one until the metal compound is completely dissolved. In this example, 10mL of 16mol / L concentrated nitric acid was used and heated at 80°C to dissolve to obtain an aqueous solution;

[0075] (2) Add 0.1% of a 1:1 mixture of glycine burning agent and azodicarbonamide and 4,4-oxobisbenzenesulfonylhydrazide to the above aqueous solution as a foaming agent , stirred until dissolved to obtain a reaction solution;

[0076] (3) Pour the reaction solution into the combus...

Embodiment 3

[0080] A process technology for one-step thermal reaction and highly dispersed multi-component nano-inorganic metal oxide single-phase crystal structure, comprising the following steps:

[0081] (1) Set Y(NO 3 ) 3 , ZrO(NO 3 ) 2 To configure 20mmole 8YSZ (8mol%Y 2 o 3 stabilized ZrO 2 ) for chemical dosage, dissolved in 50mL deionized water, added citric acid clamping agent with 1.5 times the total molar number of metal ions, and continued to stir. For example, add 5 mL of nitric acid to the solution one by one until the metal compound is completely dissolved. In this example, 10mL of 16mol / L concentrated nitric acid was used and heated at 80°C to dissolve to obtain an aqueous solution;

[0082](2) Add 0.3% of a 1:1 mixture of glycine burning agent and azodicarbonamide and 4,4-oxobisbenzenesulfonylhydrazide to the above aqueous solution as a foaming agent , stirred until dissolved to obtain a reaction solution;

[0083] (3) Pour the reaction solution into the combust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com