A preparation method of a new type of microgel bone powder for tissue repair after osteoma surgery

A microgel bone powder, tissue repair technology, applied in tissue regeneration, prosthesis, medical science and other directions, can solve problems such as failure and residual treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Example 1 Preparation of a new type of microgel bone powder that can be used for tissue repair after osteoma surgery

[0029] Step 1, preparation of mesoporous bioactive glass nanospheres.

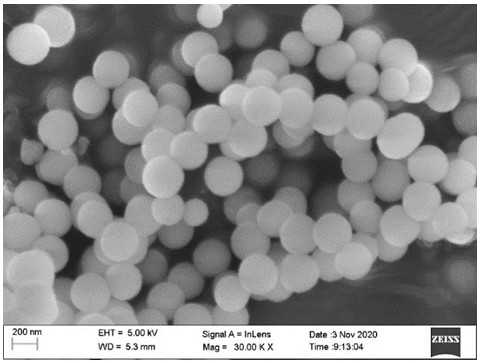

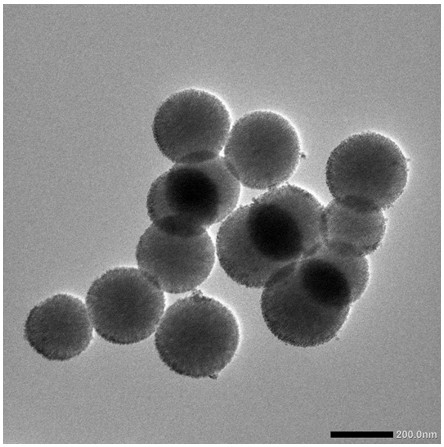

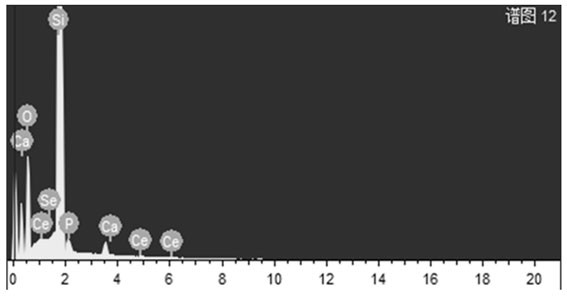

[0030] Under magnetic stirring at 500 rpm, mix 240 ml of 0.02 g / ml cetyltrimethylammonium bromide solution, 160 ml of absolute ethanol and 3 ml of 25% ammonia water, and add 7.11 g of nitric acid tetrahydrate to it Calcium, 1.30 g of cerium nitrate hexahydrate and 0.52 g of sodium selenite were fully dissolved, and then 1.4 mL of triethyl phosphate and 14 mL of tetraethyl silicate were added to it. After washing with ultrapure water three times alternately, the precipitate was kept in an oven at 60 °C for 24 h, and then the dried precipitate was calcined in a muffle furnace at 600 °C for 3 h to obtain mesoporous particles rich in selenium and cerium. Bioactive glass nanospheres.

[0031] The pore size analysis of mesoporous bioactive glass nanospheres shows that the pore size is 2...

Embodiment 2

[0034] Example 2 Preparation of a new type of microgel bone powder that can be used for tissue repair after osteoma surgery

[0035] Step 1, preparation of mesoporous bioactive glass nanospheres.

[0036] Under magnetic stirring at 500 rpm, mix 240 ml of 0.02 g / ml cetyltrimethylammonium bromide solution, 160 ml of absolute ethanol and 3 ml of 25% ammonia water, and add 7.10 g of nitric acid tetrahydrate to it Calcium, 2.60 g of cerium nitrate hexahydrate and 0.52 g of sodium selenite were fully dissolved, and then 0.80 mL of triethyl phosphate and 14 mL of tetraethyl silicate were added to it. After washing with ultrapure water three times alternately, the precipitate was kept in an oven at 60 °C for 24 h, and then the dried precipitate was calcined in a muffle furnace at 600 °C for 3 h to obtain mesoporous particles rich in selenium and cerium. The physical and chemical properties of the bioactive glass nanospheres are similar to those of the mesoporous bioactive glass nanos...

Embodiment 3

[0039] Example 3 Preparation of a new type of microgel bone powder that can be used for tissue repair after osteoma surgery

[0040] Step 1, preparation of mesoporous bioactive glass nanospheres.

[0041] Under magnetic stirring at 500 rpm, mix 240 ml of 0.02 g / ml cetyltrimethylammonium bromide solution, 160 ml of absolute ethanol and 3 ml of 25% ammonia water, and add 7.10 g of nitric acid tetrahydrate to it Calcium, 0.65 g of cerium nitrate hexahydrate and 0.52 g of sodium selenite were fully dissolved, and then 0.7 mL of triethyl phosphate and 7 mL of tetraethyl silicate were added to it. After washing with ultrapure water three times alternately, the precipitate was kept in an oven at 60 °C for 24 h, and then the dried precipitate was calcined in a muffle furnace at 600 °C for 3 h to obtain mesoporous particles rich in selenium and cerium. The physical and chemical properties of the bioactive glass nanospheres are similar to those of the mesoporous bioactive glass nanosph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com