Cell transfection device, cell transfection method and micro-channel manufacturing method

A micro-channel and cell technology, applied in chemical instruments and methods, biochemical cleaning devices, biochemical equipment and methods, etc., can solve problems such as low transfection efficiency of nano-exogenous substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

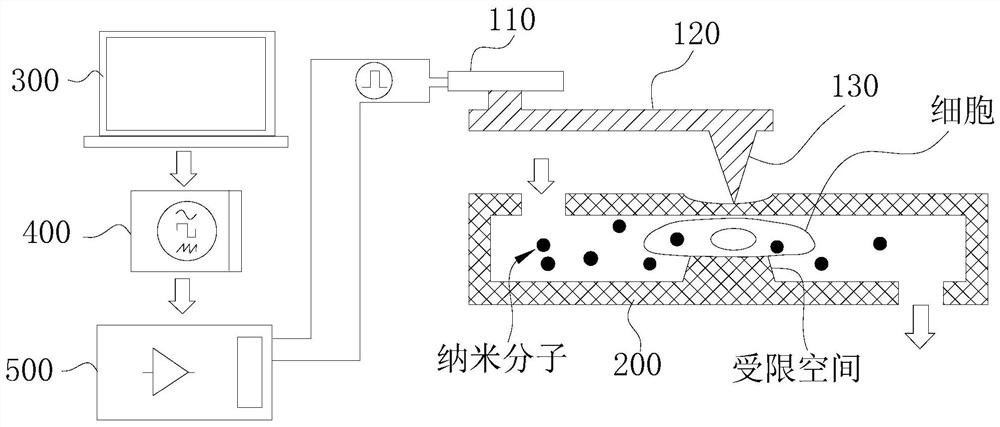

[0047] see figure 2 , shows the cell transfection device in the first embodiment of the present invention, the device includes a microfluidic chip 200, and a tunable squeezer that is located above the microfluidic chip 200 and squeezes the microfluidic chip 200 at a certain frequency Mechanism, the microfluidic chip 200 is provided with a microchannel, and a restricted space is provided in the microchannel, the cross-sectional size of the restricted space is not larger than the diameter of the cell, and a plurality of foreign substances are arranged in the microchannel, specifically, The foreign substance is a nanomolecule to be transfected. The confined space is located in the middle of the microchannel, and the size of the cross section is smaller than that of the microchannel under normal conditions. When the cells flow through the confined space, the confined space Limiting cells, the adjustable extrusion mechanism squeezes the microfluidic chip 200 and then squeezes the ...

Embodiment 2

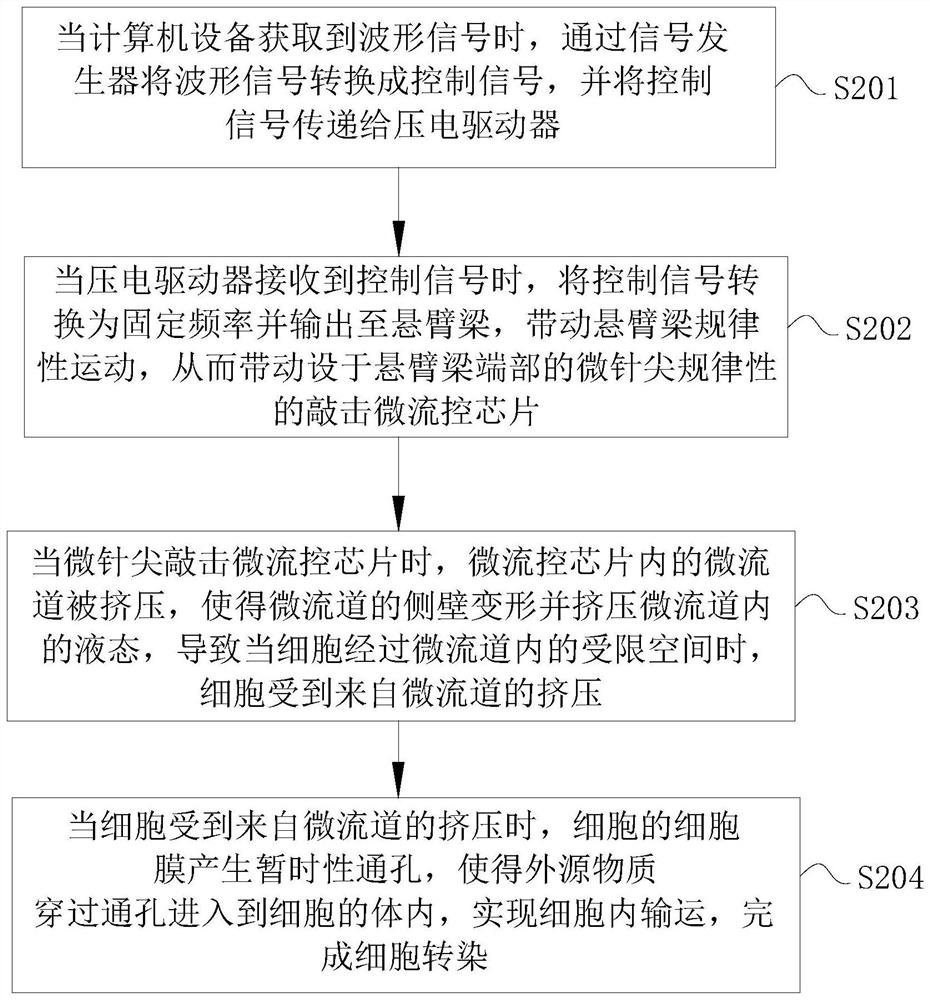

[0056] Please check image 3 , shows the cell transfection method in the second embodiment of the present invention, the cell transfection method adopts the cell transfection device in the above embodiment, and the method includes steps S201 to S204:

[0057] S201. When the computer device acquires the waveform signal, convert the waveform signal into a control signal through the signal generator, and transmit the control signal to the piezoelectric driver;

[0058] S202. When the piezoelectric actuator receives the control signal, it converts the control signal into a fixed frequency and outputs it to the cantilever beam to drive the cantilever beam to move regularly, thereby driving the microneedle tip set at the end of the cantilever beam to regularly tap the microflow control chip;

[0059] S203. When the microneedle tip hits the microfluidic chip, the microfluidic channel in the microfluidic chip is squeezed, deforming the side wall of the microfluidic channel and squeez...

Embodiment 3

[0067] Please check Figure 5 , shows the method for manufacturing the microchannel in the third embodiment of the present invention, which is applied to the microchannel in the cell transfection device in the above embodiment, and the manufacturing method includes steps S301 to S304:

[0068] S301. Obtain the target photoresist, spin-coat the target photoresist to a certain thickness on the silicon wafer, and perform pre-baking treatment on the silicon wafer coated with the photoresist;

[0069] As a specific example, the polymer material PDMS is used to fabricate and process microchannels through MEMS soft lithography technology, such as Image 6 A schematic diagram of the processing of the microfluidic chip is shown. The MEMS processing method can mass-produce microfluidic chips, reducing the processing cost of microfluidic chips.

[0070] The thickness of the photoresist can be controlled by the type of SU-8 photoresist and the number of rotations of the spin coating, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com