Modular kitchen waste and wastewater treatment process and system

A kitchen waste and wastewater treatment technology, which is applied in the field of modularized kitchen waste wastewater treatment processes and systems, can solve the problems of difficulty in finding treatment systems and processes, complex composition of kitchen waste wastewater, and large floor space, etc. Good solid-liquid separation effect, preventing anaerobic effluent from running mud, and good energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

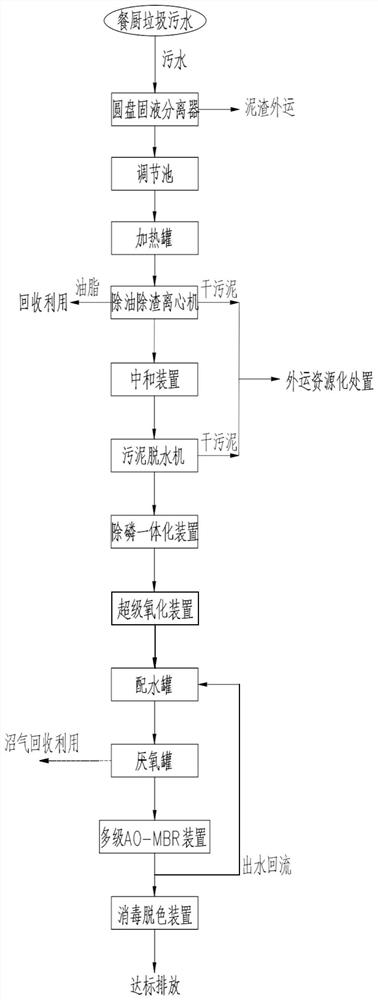

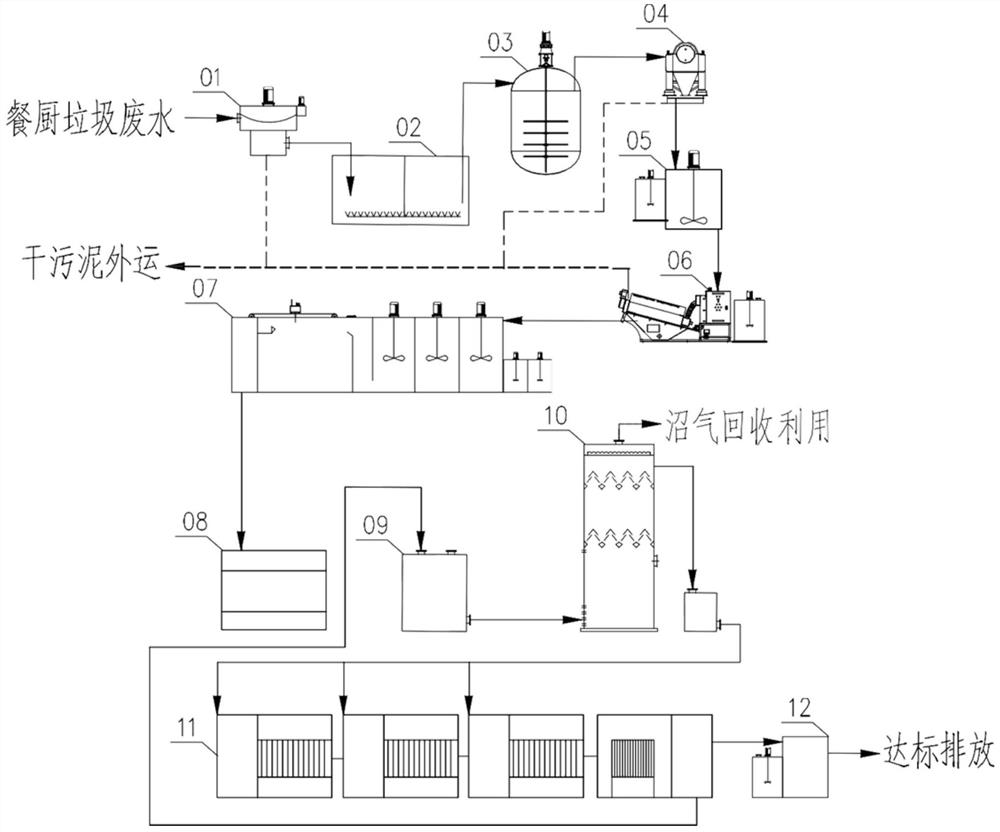

[0069] A modular food waste wastewater treatment process and its system, which is divided into the following units: disc solid-liquid separator 1, regulating tank 2, heating tank 3, oil and slag removal centrifuge 4, neutralization device 5, sludge Dehydrator 6, phosphorus removal integrated device 7, super oxidation device 8, water distribution tank 9, anaerobic tank 10, multi-stage AO-MBR device 11, disinfection and decolorization device 12,. These units are connected by pipelines to form the treatment system of the present invention.

[0070] Specifically, the disk solid-liquid separator 1 is a solid-liquid separation device, which is provided with a water inlet, a water outlet and a slag outlet, and the water outlet is connected to the regulating tank 2 through a pipeline.

[0071] The adjustment tank 2 is a waste water homogenization unit whose size matches the change cycle of waste water. The bottom is provided with a stirring air pipe and equipped with a fan.

[0072] ...

Embodiment 2

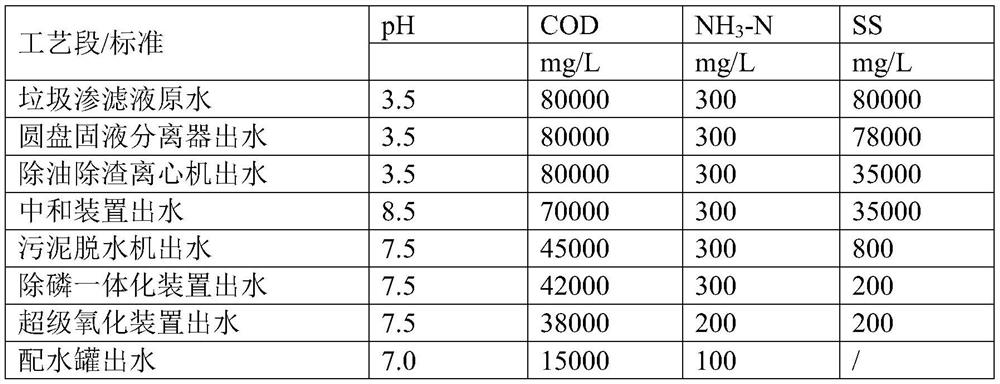

[0083] The present invention is applied to a leachate treatment demonstration project of a food waste transfer station in Shanghai. The daily treatment capacity is 100t. After treatment, the effluent of the leachate can reach the "Urban Sewer Discharge Standard (GB / T31962-2015)", each process The processing effect of the unit is shown in the table below:

[0084] Table 1 Operational water quality data of a leachate treatment demonstration project in a food waste transfer station

[0085]

[0086]

[0087] Note: The above table is the average value during operation.

[0088] As can be seen from the data in Table 1, the present invention has a good effect on the treatment of kitchen waste and wastewater, and most of the pollutants are removed, all of which can be discharged up to the standard.

[0089] In summary, compared with the prior art, the system and process provided by the present invention have good energy-saving performance, high degree of resource recovery, goo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com