Welding method for seal welding between zirconium alloy tubes and plates

A technology of zirconium alloy tubes and welding methods, which is applied in welding equipment, welding accessories, metal processing, etc., can solve the problems of high quality hidden dangers and inconvenient welding operations, and achieve the effects of good welding quality, high welding efficiency, and improved processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

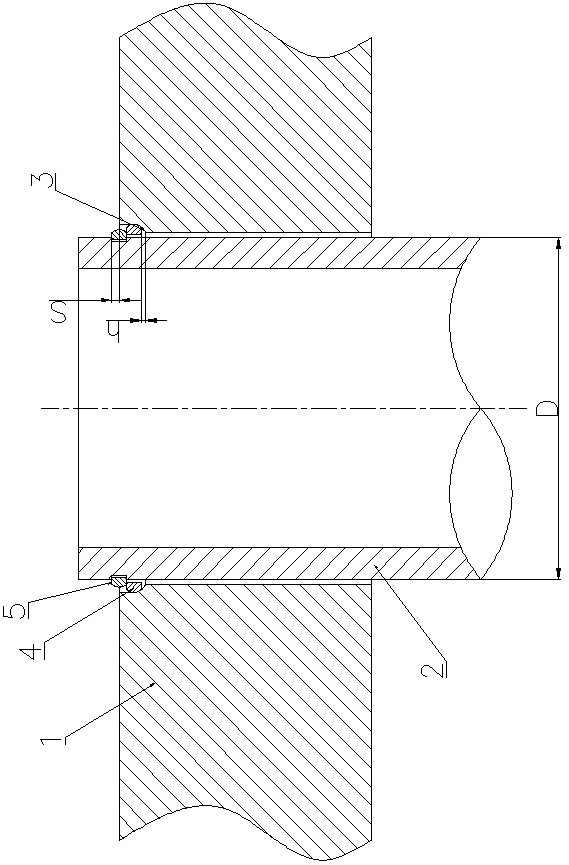

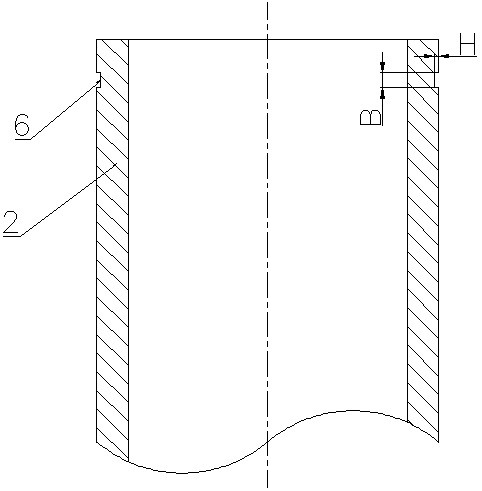

[0028] Such as Figure 1 to Figure 5 As shown, the sealing welding method between the zirconium alloy tubes and plates of the present invention, taking the sealing welding of the zirconium alloy composite tube plate and the zirconium alloy heat exchange tube using U-shaped groove as an example, includes the following steps.

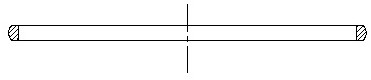

[0029] In the first step, in order to ensure that the size and plasticity of the snap ring are basically the same, the zirconium alloy welding wire to be welded is bent and cut to form a split ring, such as Figure 5 As shown, the snap ring is used together with two rings, one snap ring clips the groove on the heat exchange tube, and the other snap ring clips the groove, and its cross-sectional area is larger than that of the welding wire used for conventional zirconium alloy welding. Larger, so it has a melting point not higher than that of the base metal during self-melting, good fluidity during welding, good wettability and ability to fill gaps, and ex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com