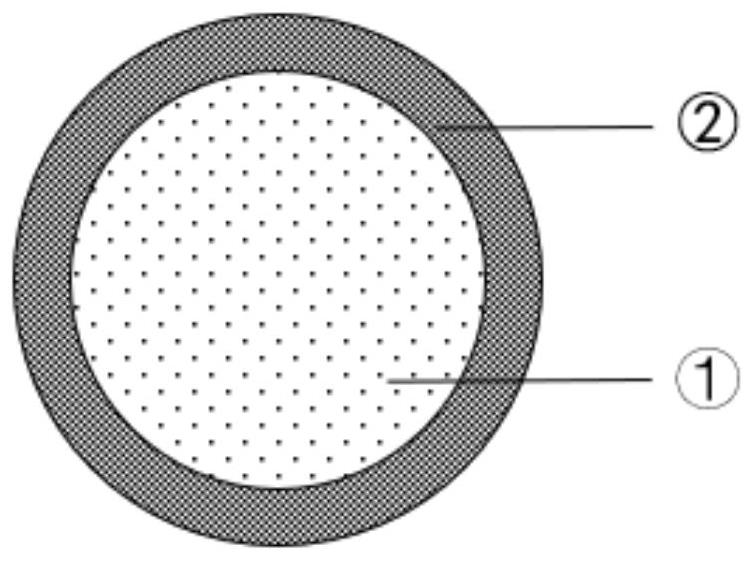

Organic coating layer, electrode material containing coating layer and lithium ion battery

A technology of electrode material and coating layer, which is applied in the field of electrochemical energy storage batteries, can solve the problems of poor lithium conduction ability and single coating method, and achieve the effect of good interface performance, excellent cycle performance and reduced side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0078]The present invention also provides a preparation method for the above-mentioned polymer, which includes the following steps: obtaining the polymer by polymerizing a composition comprising the following components: polyester polyol, polysiloxane, electrolyte salt and diisocyanate.

[0079] According to the present invention, additives are further included in the composition.

[0080] According to the present invention, a chain extender is further included in the composition.

[0081] According to the present invention, metal chlorides are further included in the composition.

[0082] According to the present invention, the composition further includes a fast ion conductor.

[0083] According to the present invention, the definition and content of each component in the composition are as described above.

[0084] According to the invention, the polymerization is carried out in a solvent. Exemplarily, the solvent includes but not limited to acetonitrile (abbreviated as ...

Embodiment approach

[0180] According to an exemplary embodiment of the present invention, the battery comprises a positive electrode and a negative electrode of the above-mentioned organic coating layer, and an electrolyte and / or an electrolyte is contained between the positive electrode and the negative electrode;

[0181] According to an exemplary embodiment of the present invention, the battery includes the above-mentioned positive electrode of the organic coating layer, the above-mentioned negative electrode of the organic coating layer, and an electrolyte and / or electrolyte solution is contained between the positive electrode and the negative electrode;

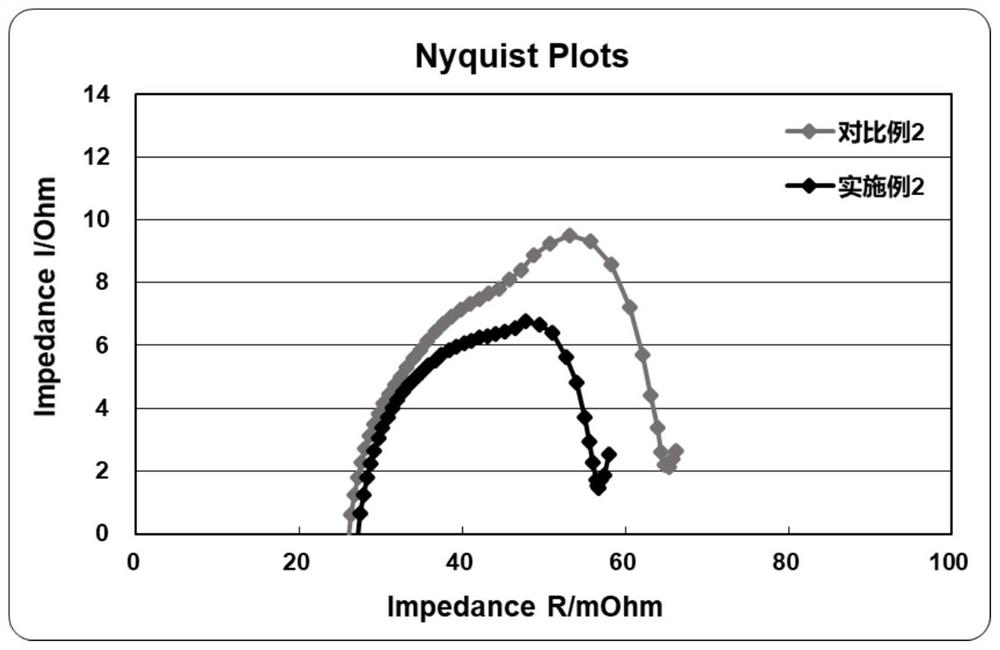

[0182]The present invention also provides a method for preparing the above-mentioned battery, which includes sequentially stacking the positive electrode, the electrolyte and / or electrolyte solution, and the negative electrode together, and the battery can be obtained after vacuum packaging. The technical solutions of the present invention w...

Embodiment 1

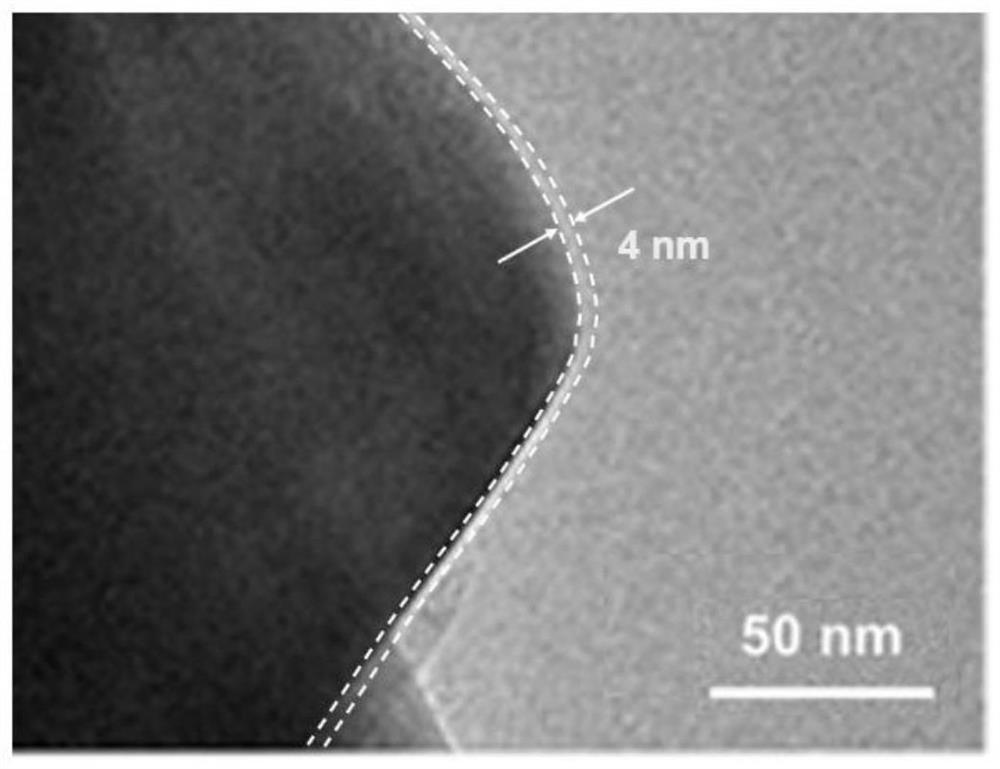

[0188] Preparation of organic coating layer coated electrode active material:

[0189] (1) Dissolve 26.8g of polycaprolactone diol and 11.2g of hydroxyl-terminated polytrimethicone in ACN to form a solution with a solid content of 5%, and fully stir at 45°C for 3 hours under argon to form a precursor solution A;

[0190] (2) Add 4.4g of diphenylmethane diisocyanate and 1.2g of 4,4'-bipyridine to the above precursor solution A, and continue heating and stirring at 45°C for 1h in an argon atmosphere to form precursor solution B;

[0191] (3) Add 0.5g of 1,4-butanediol (BDO) and 6.7g of LiTFSI into the above-mentioned precursor solution B, and continue to fully stir for 6 hours to form a uniform precursor solution C;

[0192] (4) Dissolve 3 g of zinc chloride in ACN and fully stir to form a homogeneous solution with a concentration of 3%, add it to the above precursor solution C, and fully mix and stir at 500 rpm for 4 hours at room temperature;

[0193] (5) 500g of positive el...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com