Assembled integrated rock plate as well as preparation method and application thereof

An integrated slate, prefabricated technology, used in buildings, building structures, covering/lining, etc., can solve the problems of poor fireproof, moisture-proof and mildew-proof performance of siding, and achieve easy daily maintenance, simplified construction procedures, and fireproof performance. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] This application also provides a preparation method for an assembled integrated slate, comprising the following steps:

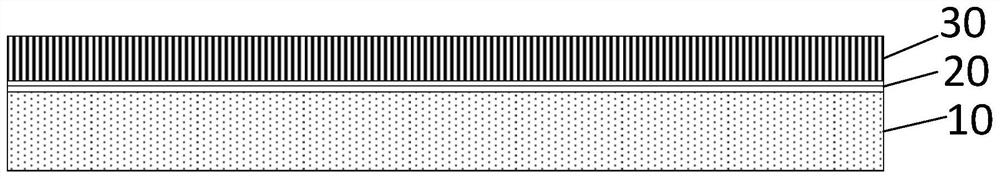

[0048] An adhesive is applied on the surface of the rock plate 30, and the flame-retardant crystal plate 10 and the rock plate 30 are bonded and fixed.

[0049] Further, the preparation method of the assembled integrated slate also includes the following steps:

[0050] (1) Ball mill and sieve the raw materials of the second layer 31, remove iron, add water to make a slurry stale for 10-24 hours, spray dry the slurry to make powder, and obtain the powder of the second layer 31;

[0051] (2) The raw materials of the first layer 32 are ball milled, sieved, iron removed, and water is added to make a slurry stale for 10-24 hours, and the slurry is spray-dried to make powder to obtain the powder of the first layer 32;

[0052] (3) First lay a layer of powder of the second layer 31 in the mold, and then spread a layer of powder of the first layer 32;

[0...

Embodiment 1

[0062] A prefabricated integrated rock plate is made by compounding a 3mm thick rock plate and a 6mm thick flame retardant crystal plate through an adhesive.

[0063] Among them, the slate includes a second layer with a thickness of 2mm and a first layer with a thickness of 1mm from bottom to top;

[0064] The second layer, in parts by weight, includes the following raw materials:

[0065] 11 parts of mullite, 6 parts of kaolin, 15 parts of potassium feldspar, 12 parts of bauxite, 11 parts of dolomite, 8 parts of albite, 5 parts of carbon fiber;

[0066] The first layer, in parts by weight, includes the following raw materials:

[0067] 16 parts of mullite, 6 parts of kaolin, 15 parts of potassium feldspar, 11 parts of bauxite, 11 parts of allophane, 9 parts of albite, 3 parts of zinc oxide.

[0068] A method for preparing an assembled integrated slate, comprising the following steps:

[0069] (1) Ball mill and sieve the raw materials of the second layer, remove iron, add w...

Embodiment 2

[0077] A prefabricated integrated rock plate is composed of a 3mm thick rock plate and an 8mm thick flame-retardant crystal plate through adhesives.

[0078] Among them, the slate includes a second layer with a thickness of 2mm and a first layer with a thickness of 1mm from bottom to top;

[0079] The second layer, in parts by weight, includes the following raw materials:

[0080] 14 parts of mullite, 10 parts of kaolin, 23 parts of potassium feldspar, 14 parts of bauxite, 15 parts of dolomite, 13 parts of albite, 10 parts of carbon fiber;

[0081] The first layer, in parts by weight, includes the following raw materials:

[0082] 19 parts of mullite, 9 parts of kaolin, 25 parts of potassium feldspar, 15 parts of bauxite, 15 parts of allophane, 13 parts of albite, 8 parts of zinc oxide.

[0083] A method for preparing an assembled integrated slate, comprising the following steps:

[0084] (1) Ball mill and sieve the raw materials of the second layer, remove iron, add water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com