Friction filler, friction material composition, friction material and application thereof

A friction material and composition technology, applied in the field of friction materials, can solve the problems of poor elimination of polygonal contours on the surface of wheels, limited cleaning and repairing effect of abrasive materials, insufficient wear resistance of abrasive sub-materials, etc., to improve cleaning ability and Reshaping ability, avoiding harmful thermal effects, eliminating micro cracks and wheel out-of-roundness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

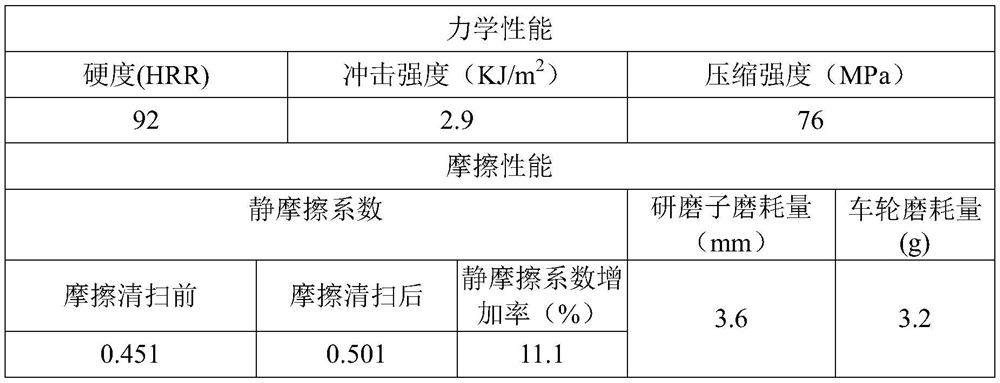

Embodiment 1

[0073] This embodiment provides a friction material, the preparation method of which includes:

[0074] 1. Weigh 350g of nitrile rubber powder, 1150g of phenolic resin powder, 840g of barium sulfate, 430g of flake graphite, 550g of copper fiber, 183g of copper filings, 310g of reduced iron powder, 150g of zirconium dioxide, 200g of white corundum, 240g of cryolite, chlorine 22g fatty acid ester, 220g potassium feldspar, 35g zinc oxide, 35g accelerator, 35g stearic acid, 35g sulfur.

[0075] 2. Pour the weighed raw materials into the production-type double-cone high-speed mixer, and add toluene whose mass is 1% of the total mass of the above-mentioned raw materials at the same time, set the machine speed to 60 rpm, mix for 35 minutes, and mix well. The obtained mixture was hot-pressed with a 315-ton hydraulic press, with a molding pressure of 30 MPa, a hot-pressing temperature of 160° C., and a hot-pressing time of 35 minutes. After hot-press forming, according to the set curi...

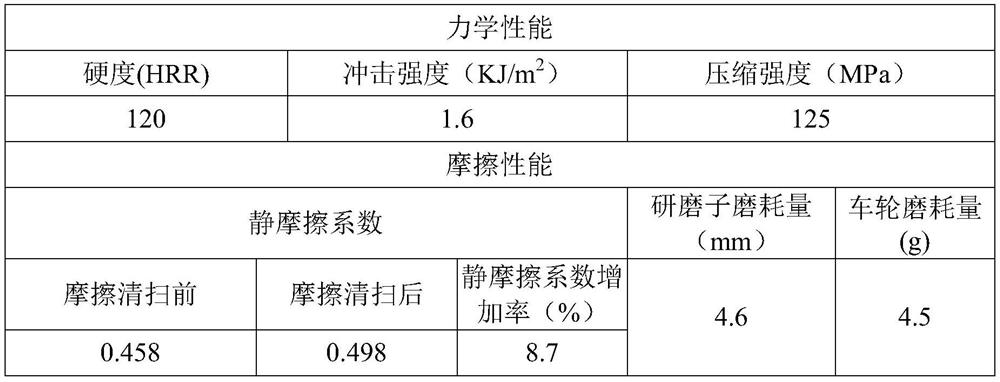

Embodiment 2

[0080] This embodiment provides a friction material, the preparation method of which includes:

[0081] 1. Weigh 400g of nitrile rubber powder, 1100g of phenolic resin powder, 760g of barium sulfate, 460g of flake graphite, 600g of copper fiber, 201g of copper filings, 330g of reduced iron powder, 120g of zirconium dioxide, 220g of white corundum, 230g of cryolite, chlorine 24g fatty acid ester, 200g potassium feldspar, 40g zinc oxide, 40g accelerator, 40g stearic acid, 40g sulfur.

[0082] 2. Pour the weighed raw materials into the production-type double-cone high-speed mixer, set the machine speed to 60 rpm, and mix for 35 minutes. After mixing evenly, use the 315-ton hydraulic press to hot-press the above-mentioned mixture to form it. The pressure is 30MPa, the hot-pressing temperature is 160°C, and the hot-pressing time is 35min. After hot-press forming, according to the set curing program, use an oven to perform secondary curing on the hot-press-formed material to obtain...

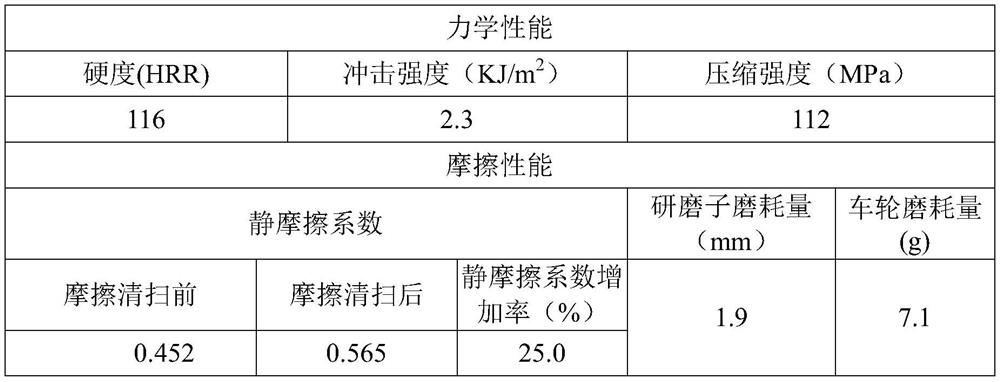

Embodiment 3

[0087] The present embodiment provides a friction material, and its preparation method includes:

[0088] 1. Weigh nitrile rubber powder 450g, phenolic resin powder 1050g, barium sulfate 680g, flake graphite 490g, copper fiber 650g, copper filings 226g, reduced iron powder 360g, zirconium dioxide 140g, white corundum 180g, cryolite 210g, chlorine Fatty acid ester 29g, potassium feldspar 180g, zinc oxide 45g, accelerator 45g, stearic acid 45g, sulfur 45g.

[0089] 2. Pour the weighed raw materials into the produced double-cone high-speed mixer, and at the same time add toluene whose mass is 1% of the total mass of the above raw materials, set the machine speed to 60 rpm, and mix for 35 minutes. The formed mixture was hot-pressed with a 315-ton hydraulic press, the molding pressure was 30 MPa, the hot-pressing temperature was 160° C., and the hot-pressing time was 35 minutes. After hot-pressing molding, the material after hot-pressing molding is secondary-cured in an oven accor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com