Copper sheet surface treatment method

A technology of surface treatment and copper sheet, which is applied in the field of DCB substrate preparation, can solve the problems of insufficient reliability of finished product quality, low efficiency of copper surface roughening, and influence on post-process stability, and achieve the effect of improving wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

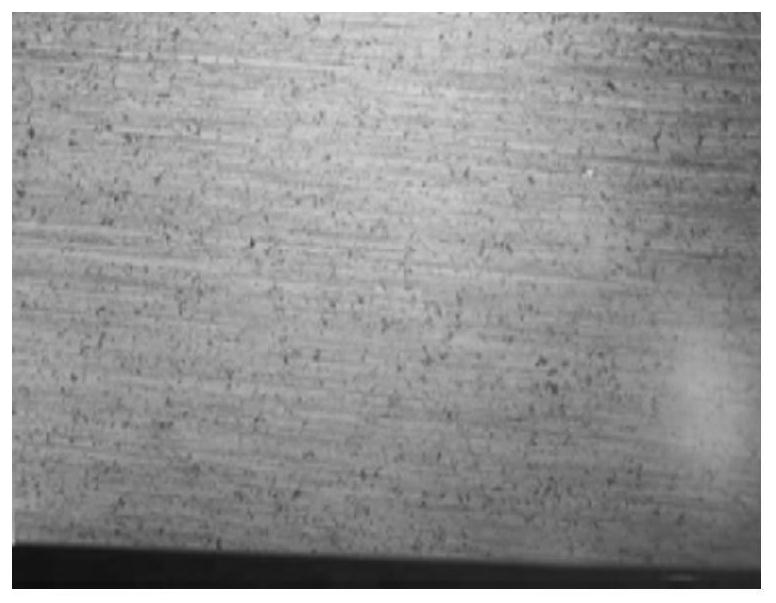

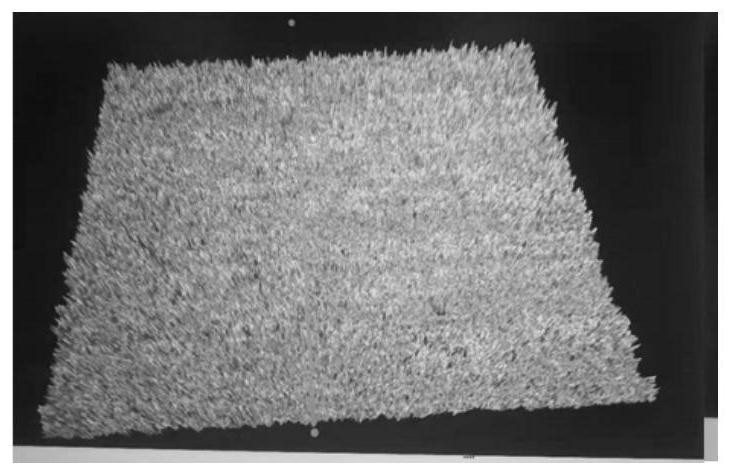

[0039] S1: Put the copper sheet into the micro-etching solution, and check it after overflow washing. The micro-etching solution is prepared by mixing sulfuric acid and sodium persulfate, the concentration of the sulfuric acid is 0.2mol / L, and the sodium persulfate The mass concentration in the microetching solution is 2%;

[0040] S2: configure emery suspension, the emery purity in the emery suspension is 99%, and the emery is 220#;

[0041] S3: Spray the prepared emery suspension onto the surface of the copper sheet, the injection pressure is 1 bar, and the conveying speed of the copper sheet during the spraying is 1m / min;

[0042]S4: The copper sheet after sandblasting is sequentially washed by overflow water, pressurized water, ultrasonic water, and twice pressurized water, then cooled to 18° C., and dried to obtain the treated copper sheet.

Embodiment 2

[0044] S1: Put the copper sheet into the micro-etching solution, and check it after overflow washing. The micro-etching solution is prepared by mixing sulfuric acid and sodium persulfate, the concentration of the sulfuric acid is 1mol / L, and the sodium persulfate is The mass concentration in the microetching solution is 3%;

[0045] S2: configure emery suspension, the emery purity in the emery suspension is 99.2%, and the emery is 240#;

[0046] S3: Spray the prepared emery suspension onto the surface of the copper sheet, the injection pressure is 1.5bar, and the conveying speed of the copper sheet during the spraying is 1.2m / min;

[0047] S4: The copper sheet after sand blasting is sequentially washed by overflow water, pressurized water, ultrasonic water, and twice pressurized water, then cooled to 19° C., and dried to obtain the treated copper sheet.

Embodiment 3

[0049] S1: Put the copper sheet into the microetching solution, and check it after overflow washing. The microetching solution is prepared by mixing sulfuric acid and sodium persulfate. The concentration of the sulfuric acid is 2mol / L, and the sodium persulfate is The mass concentration in the microetching solution is 6%;

[0050] S2: configure emery suspension, the emery purity in the emery suspension is 99.3%, and the emery is 250#;

[0051] S3: Spray the prepared emery suspension onto the surface of the copper sheet, the injection pressure is 1.6bar, and the conveying speed of the copper sheet during the spraying is 1.4m / min;

[0052] S4: The copper sheet after sandblasting is sequentially washed by overflow water, pressurized water, ultrasonic water, and twice pressurized water, then cooled to 18-25° C., and dried to obtain the treated copper sheet.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com