A kind of metal corrosion resistant insensitive ammunition and preparation method thereof

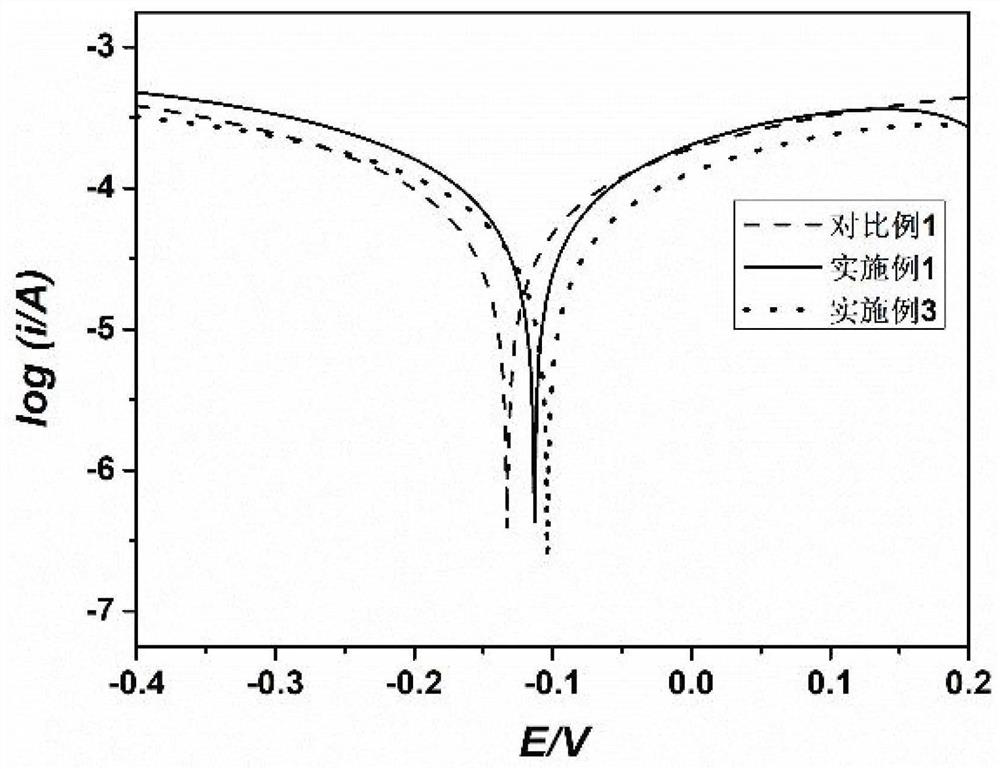

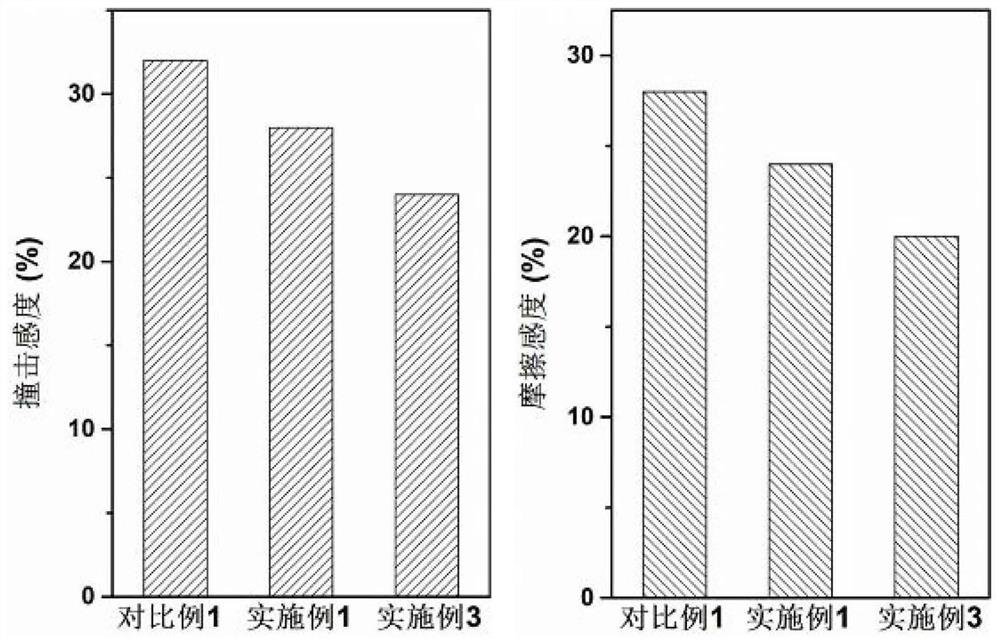

A corrosion-resistant, metal-resistant technology, used in ammunition, separation methods, chemical instruments and methods, etc., can solve problems such as unfavorable weapons and equipment application, NTO energy reduction, etc., to improve metal corrosion resistance, improve electrical conductivity, and stabilize chemistry. and the effect of the electrochemical reaction interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The present invention also provides a preparation method of the above-mentioned metal corrosion-resistant insensitive ammunition, which specifically includes the following steps:

[0034] (1) Slowly add a hydrofluoric acid solution with a mass fraction of ≥ 40% into the MAX phase with a particle size of ≤ 200 mesh, and carry out an etching reaction at 55~70 ° C for 24 hours to etch away the aluminum layer in the MAX phase, and then filter, washing and drying to obtain layered MXene;

[0035] The mass volume ratio of MAX phase and hydrofluoric acid solution is 1g:10mL;

[0036] (2) Dissolving the above-mentioned layered MXene and NTO raw materials with a purity of ≥98% in absolute ethanol, and evaporating and crystallizing under ultrasonic conditions to obtain a metal corrosion-resistant insensitive ammunition, the mass percentage of MXene and NTO in absolute ethanol is 5 %~15%; ultrasonic power is 500W; evaporation crystallization temperature is 60~80℃. The mass-volum...

Embodiment 1

[0038] Embodiment 1 of the present invention provides a method for preparing a metal corrosion-resistant insensitive ammunition, which specifically includes the following steps:

[0039] (1) Put 2 g of Ti 3 AlC 2 It was added to 20 mL of 49% hydrofluoric acid solution and reacted at 60 °C for 24 h to etch away Ti. 3 AlC 2 The aluminum layer in , was filtered, washed and dried to obtain layered MXene;

[0040](2) The obtained MXene and NTO were mixed at a mass ratio of 1:20 to obtain a mixture, 10 g of the mixture was dissolved in 100 mL of absolute ethanol at 55 °C, and then heated to 65 °C to maintain the temperature, and under ultrasonic conditions (ultrasonic power) Evaporation crystallization was carried out at 500W), and the MXene / NTO composite was obtained after the anhydrous ethanol was completely evaporated, which was an insensitive ammunition resistant to metal corrosion.

Embodiment 2

[0042] Embodiment 2 of the present invention provides a method for preparing a metal corrosion-resistant insensitive ammunition, which specifically includes the following steps:

[0043] (1) Put 2 g of Ti 3 AlC 2 It was added to 20 mL of 49% hydrofluoric acid solution and reacted at 60 °C for 24 h to etch away Ti. 3 AlC 2 The aluminum layer in , was filtered, washed and dried to obtain layered MXene;

[0044] (2) The obtained MXene and NTO were mixed at a mass ratio of 1:15 to obtain a mixture, 10 g of the mixture was dissolved in 100 mL of absolute ethanol at 55 °C, and then the temperature was raised to 65 °C to maintain the temperature, and under ultrasonic conditions (ultrasonic power Evaporation crystallization was carried out at 500W), and the MXene / NTO composite was obtained after the anhydrous ethanol was completely evaporated, which was an insensitive ammunition resistant to metal corrosion.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com