Kitchen waste treatment process

A food waste and treatment process technology, applied in the field of food waste treatment, can solve the impact of surrounding residents, a large amount of waste gas, waste water, impact on the environment and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to achieve the above object, the technical solution of the present invention is: a kitchen waste treatment process, characterized in that it comprises the following steps:

[0025] S1: Transport the food waste to the pre-treatment system for screening, pulping and heating;

[0026] S2: Transport the food waste processed by the pre-treatment system to the recycling system for three-phase separation, and separate out crude oil, slag and waste water;

[0027] S3: The crude oil and slag in the recycling system are processed and recycled, and the waste water enters the anaerobic reactor through the pretreatment system;

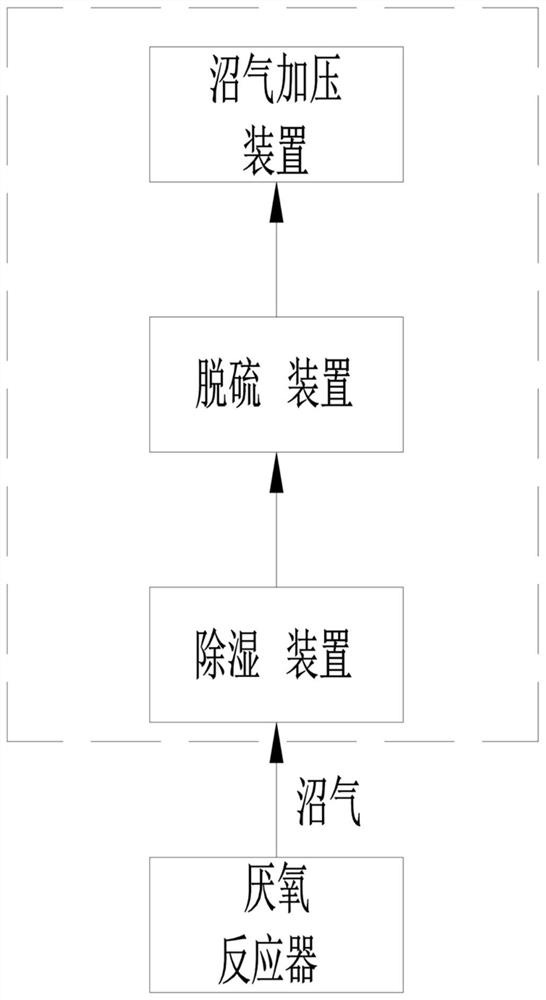

[0028] S4: The biogas produced by the anaerobic reactor is sent to the energy recovery system, and the wastewater and slick oil produced by the anaerobic reactor are sent to the post-treatment system;

[0029] S5: The post-treatment system purifies and discharges the generated wastewater, and the activated sludge generated by the post-treatment sys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com