High-performance carbon-carbon crucible surface coating and preparation method thereof

A surface coating and carbon crucible technology, which is applied in the field of high-performance carbon-carbon crucible surface coating and its preparation, can solve the problem of unsatisfactory high temperature oxidation resistance of the outer coating, formation of cavities or pores on the surface of the protective film, coating Loss of oxidation protection ability and other problems, to achieve the effect of expanding the range of high temperature use, reducing the oxygen penetration rate, and excellent high temperature oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

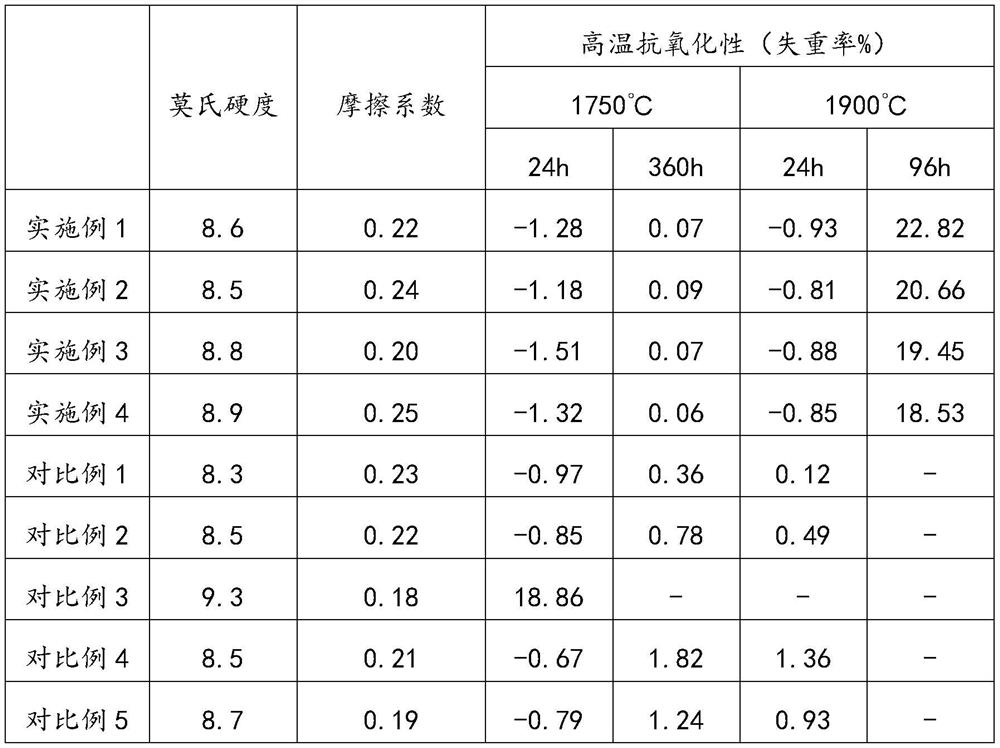

Examples

Embodiment 1

[0036] The carbon carbon crucible surface coating provided in this embodiment is from the SiC transition layer and LAB 6 / Y 3 Al 5 O 12 The outer coat layer, which is first deposited in the surface of the carbon carbon crucible to deposit the SiC transition layer, and then coat the Lab by the slurry method. 6 / Y 3 Al 5 O 12 External coat. The method of preparing the surface coating of the carbon carbon crucible, comprising the steps of:

[0037] (1) Matrix pretreatment: Place the carbon carbon crucible in a container configured with ethanol, washed in an ultrasonic cleaner, ultrasonic 15min, and repeatedly cleaned 3 times to remove the stains of the carbon carbon.

[0038] (2) SI powder, C powder and B 2 O 3 In the ball mill, the ball mill is 600r / min, with deionized water as a medium, ball milling 18h, dry, uniform A powder, Si powder, C powder and Al 2 O 3 The powder is placed in a ball mill, the ball mill is 600 r / min, with deionized water as a medium, ball milling 18h, a...

Embodiment 2

[0048] The composition, formulation, and preparation method of the surface coating provided in this embodiment are the same as that in Example 1, as follows:

[0049] In this embodiment, the Si powder, C powder and B of the A powder 2 O 3 The mass ratio of powder is 4.5: 1: 0.8.

[0050] In this embodiment, the Si powder, C powder and Al of B powder 2 O 3 The mass ratio of powder is 4.5: 1: 1.

[0051] In this example, B powder, LA 2 O 3 Y 3 Al 5 O 12 Powder and Al powder mass ratio is 2: 4: 1: 0.3.

[0052] In the step (5) of the present embodiment, the binder used is a polyvinyl butylade, and the mass of the binder is 5% of the mixed powder mass, and the mass of deionized water used is a mixed powder mass. 3 times.

[0053] The heat treatment process of step (5) of the present embodiment is: set the pressure in the high temperature hot press furnace to 15 MPa, first temperature up to 150 ° C, heat insulation 2 h at the rate of 5 ° C / min; then heat up at a rate of 10 ° C / min ...

Embodiment 3

[0055] The composition, formulation, and preparation method of the surface coating provided in this embodiment are the same as that in Example 1, as follows:

[0056] In this embodiment, the Si powder, C powder and B of the A powder 2 O 3 The mass ratio of powder is 4: 1: 0.7.

[0057] In this embodiment, the Si powder, C powder and Al of B powder2 O 3 The mass ratio of powder is 4: 1: 1.

[0058] In this example, B powder, LA 2 O 3 Y 3 Al 5 O 12 Powder and Al powder mass ratio is 1: 4: 1: 0.2.

[0059] In the step (5) of the present embodiment, the binder used is a polyvinyl butylade, the use of the binder is 4% of the mixed powder mass, and the mass of deionized water used is a mixed powder quality. 2 times.

[0060] The heat treatment process of the step (5) of the present embodiment is: set the pressure in the high temperature hot press furnace to 12 MPa, first temperature rising at a rate of 4 ° C / min to 180 ° C, heat insulation 2 h; then warmed at the rate of 8 ° C / min U...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com