Magnetic control nano motor overflowing adsorption reaction assembly

An adsorption reaction and magnetic nanotechnology, which is applied in the field of pollutant treatment, can solve the problems that nano-adsorption materials cannot be widely used, the number of cycles of use is low, and the application cost is high, and the effect of good adsorption effect, easy replacement, and increased utilization efficiency can be achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Example 1: In this example, the magnetically controlled nanomotor overcurrent adsorption reaction component and its application in hydrogen sulfide poisonous gas purification, the concentration of hydrogen sulfide in the gas to be purified is 3.46mg / m 3 ;

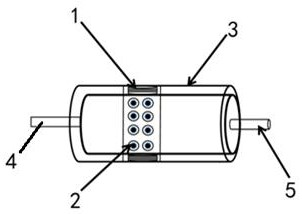

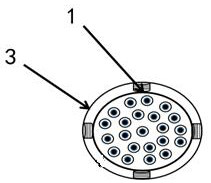

[0018] Such as figure 1 , 2 As shown, the magnetron nanomotor overcurrent adsorption reaction assembly includes a shell 3 with an interlayer, the outer wall of the shell is a hollow cylinder of epoxy resin, the inner wall of the shell is a hollow cylinder of acrylic, and the two ends of the shell are provided with inlets. 4 and exit 5, four magnetic field generators are symmetrically arranged in the interlayer of the housing to form a magnetic confinement area, the magnetic field generator is a Helmertz coil, the Helmertz coil is 20 turns, and the applied voltage is 360V; the adsorption magnetic nanomotor is placed In the magnetic confinement region, the adsorbed magnetic nanomotors are suspended and dispersed in t...

Embodiment 2

[0020] Example 2: The magnetron nanomotor overcurrent adsorption reaction component and its SO 2 , NOx, HF gas purification application, SO in the gas to be treated 2 The concentration is 4.16mg / m 3 , NOx gas concentration is 2.14mg / m 3 , HF gas concentration is 3.54mg / m 3 .

[0021] In this embodiment, the structure of the device is the same as in Embodiment 1, except that the outer wall of the housing is a polyurethane hollow cylinder, and the inner wall of the housing is a hollow cylinder of PVDF; I, Cui J.B, et al. Structural and magnetic properties ofnanostructuredMn-Al-C magnetic materials. Journal of Magnetism and MagneticMaterials, 2007, 308: 214 ~ 226 method) placed in hydrophilic ionic liquid 1-propyl- 3-Methylimidazolium chloride salt [PMIm]Cl, using the equal volume impregnation method, shaking reaction at 1000rpm for 30min, filtering, and drying the solid at 60°C; the magnetic field generator is a Helmertz coil, and the Helmertz coil is 300 turns, the applied...

Embodiment 3

[0023] Example 3: The magnetron nanomotor overcurrent adsorption reaction component and its application in the purification of heavy metal polluted water, the concentration of As in the wastewater to be treated is 3.46mg / m 3 , Cr concentration is 5.31mg / m 3 .

[0024] In this embodiment, the structure of the device is the same as in Embodiment 1, except that the outer wall of the housing is a hollow cylinder of acrylic resin, and the adsorption magnetic nanomotor is made of nano-Pt-Co at room temperature (refer to Wu Shuai. Pt-Co alloy nanocatalyst preparation and Catalytic performance research [D]. Kunming University of Science and Technology, 2017.) placed in β-cyclodextrin solution with a mass concentration of 10%, using equal volume impregnation method, oscillating reaction at 800rpm for 40min, filtering, solid 60 Prepared by drying at ℃; the magnetic field generator is a Helmertz coil, the Helmertz coil has 100 turns, and the applied voltage is 220V;

[0025] The waste ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com