Preparation of Mn-Ce-Sb/hierarchical porous ZSM-5 catalyst and low-temperature denitration application thereof

A technology of ZSM-5 and mn-ce-sb, which is applied in the field of molecular sieve catalysis, can solve the problems of single pore and poor catalytic performance of ordinary molecular sieves, so as to improve NOx removal rate, improve anti-SO2 poisoning performance, and improve low-temperature denitrification catalysis The effect of efficiency and sulfur resistance performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The preparation method of a Mn-Ce-Sb / hierarchical channel ZSM-5 catalyst provided by the embodiment of the present invention comprises the following steps:

[0040] A. Synthesis of multi-level channel ZSM-5 molecular sieve

[0041] Step 1, according to the volume ratio (4-20): 1, add organosilane TPOAC to the microporous template solution, and stir to obtain solution A; the mass concentration of the microporous template solution is 50%;

[0042] Wherein, the microporous template agent is any one of tetrapropylammonium hydroxide (TPAOH), n-butylamine or ethylenediamine. Organosilanes were used as structure-directing agents, using dimethyloctadecyl[3-(trimethoxysilyl)propyl]ammonium chloride (TPOAC).

[0043] Step 2, according to the volume ratio (420-520): 1:280, add NaOH to the solution A, then add the silicon source dropwise, and stir to obtain a uniform mixed solution B;

[0044] Wherein, the silicon source adopts any one of tetraethyl orthosilicate (TEOS), silica g...

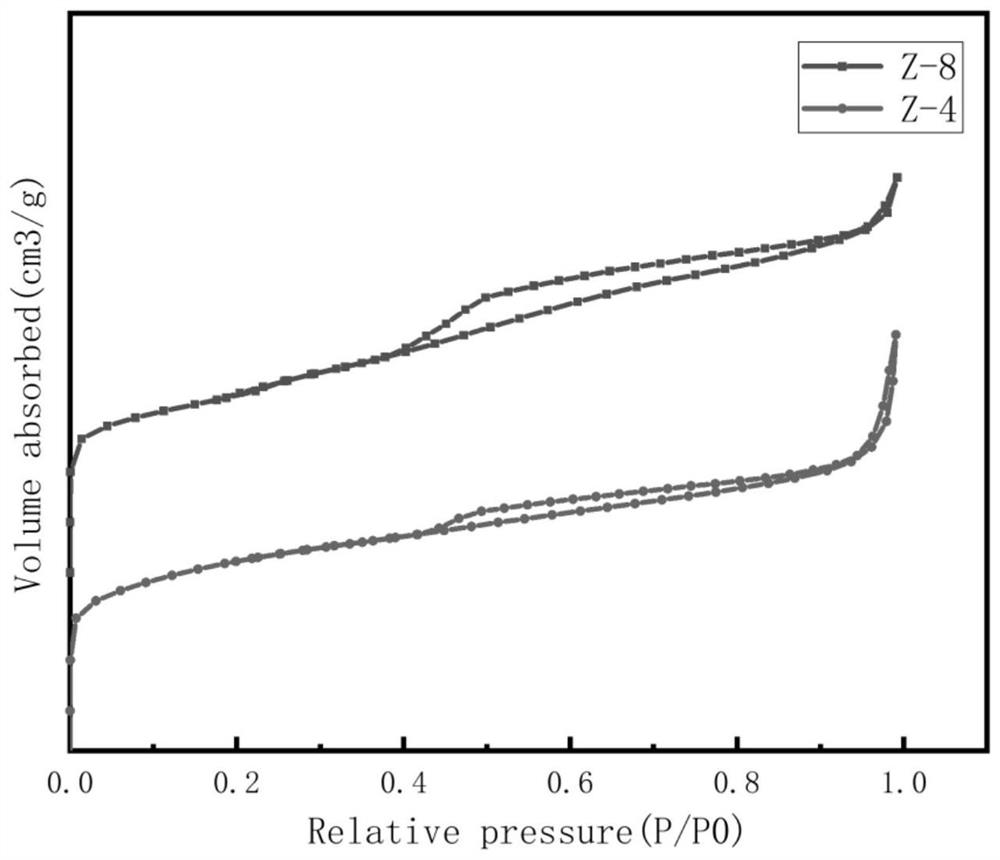

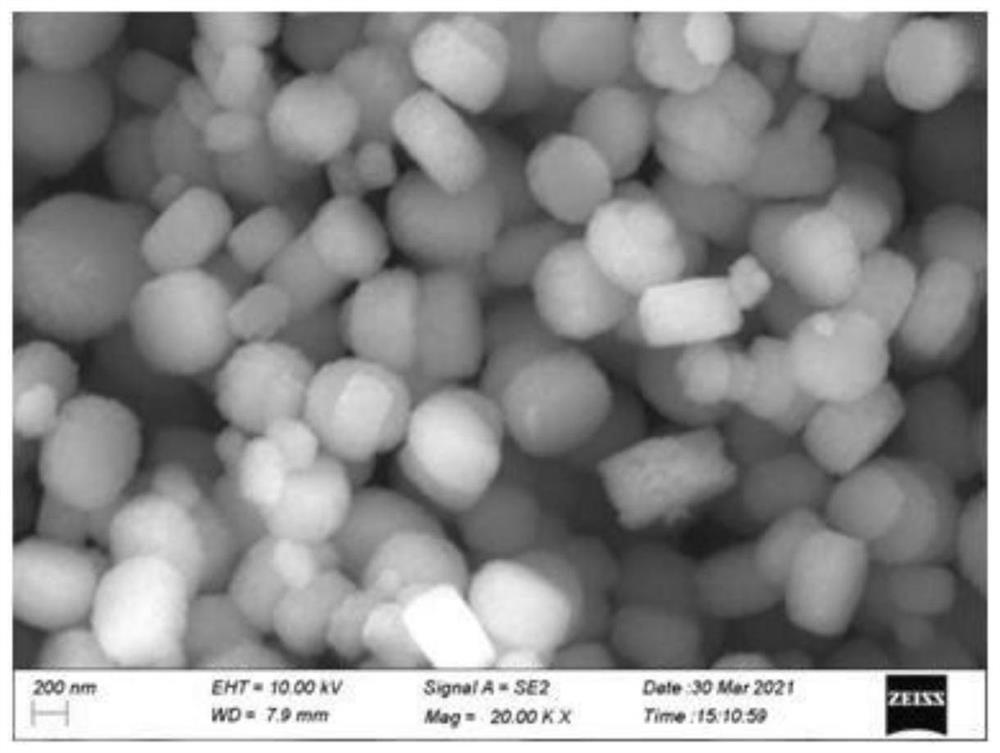

Embodiment 1

[0057] The multi-level channel ZSM-5 molecular sieve was prepared by the soft template method and used as the carrier, and the Mn metal element was used as the active component, and the Mn element was loaded on the multi-level channel ZSM-5 molecular sieve by the impregnation method, wherein the mass fraction of Mn 20%.

[0058] A, deionized water is added in tetrapropyl ammonium hydroxide (TPAOH), configuration mass concentration is 50% microporous template solution, according to volume ratio 20: 1 microporous template solution tetrapropylammonium hydroxide (TPAOH) Add organosilane TPOAC to TPAOH) to obtain solution A, stir at room temperature for 20min, then add NaOH to solution A according to the volume ratio of 500:1:280, then add tetraethyl orthosilicate (TEOS) dropwise, stir at room temperature for 1h to obtain a uniform mixture Solution B; then add sodium metaaluminate NaAlO according to the volume ratio of 150:1 2 , stirred at room temperature for 30 minutes until the...

Embodiment 2

[0061] Hierarchical channel ZSM-5 molecular sieves were prepared by soft template method as carrier. Using Mn and Ce metal elements as active components, the Mn and Ce metal elements are supported on the multi-stage pore ZSM-5 molecular sieve by impregnation method, wherein the loading ratio of Mn and Ce is 0.85:0.15, and the mass of (Mn+Ce) The score is 20%.

[0062] A. Add deionized water to n-butylamine, configure a microporous template solution with a mass concentration of 50%, and add organosilane TPOAC to the microporous template n-butylamine solution according to the volume ratio of 18:1 to obtain solution A, at room temperature Stir for 20 minutes, then add NaOH to solution A according to the volume ratio of 520:1:280, then add silica gel drop by drop, stir at room temperature for 1 hour to obtain a uniform mixture B; then add aluminum isopropoxide according to the volume ratio of 145:1, Stir for 30 minutes until the aluminum is completely dissolved, then move to a re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com