Sapphire chemical mechanical polishing liquid and its application

A chemical mechanical and polishing liquid technology, which is applied in the direction of polishing compositions containing abrasives, grinding machine tools, metal processing equipment, etc., can solve the problems of poor storage stability, unsuitable cleaning process, and low polishing efficiency, so as to reduce crystallization and improve The effect of high polishing rate and material removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

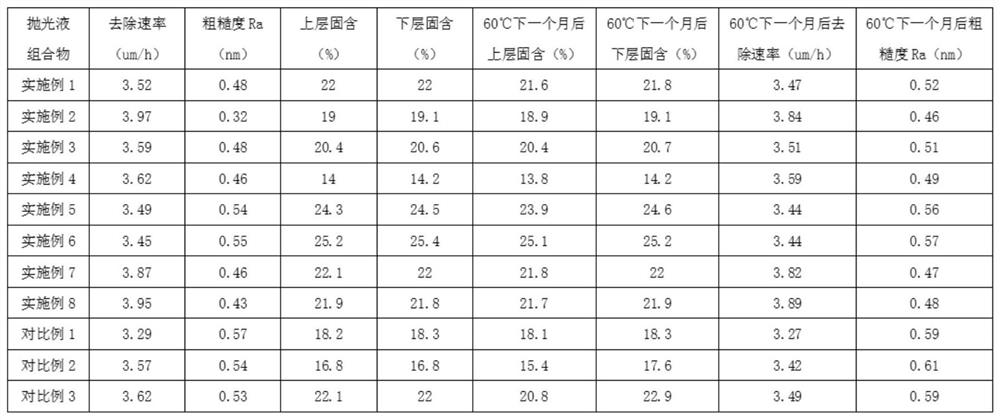

Examples

preparation example Construction

[0035] Specifically, the preparation method of the sapphire chemical mechanical polishing liquid, for example, includes the following steps: taking a certain solid content of silica sol and uniformly dispersing it in a half amount (half of the required amount of deionized water in the sapphire polishing composition) deionized water In water, the solution is called A; then slowly add manganese-containing complexing agent to the other half of deionized water, stir for 5 minutes, add surfactant, stir for 5 minutes, and then add an appropriate amount of pH adjuster to make the pH value between 8- Within the range of 12, stir for 5 minutes, and the solution is called B; then slowly add solution B to solution A, and stir for 30 minutes to obtain the sapphire chemical mechanical polishing liquid composition. The appropriate amount of pH adjuster can be selected according to needs with different concentrations of pH adjuster, and on the basis of ensuring that the content of the pH adju...

Embodiment 1

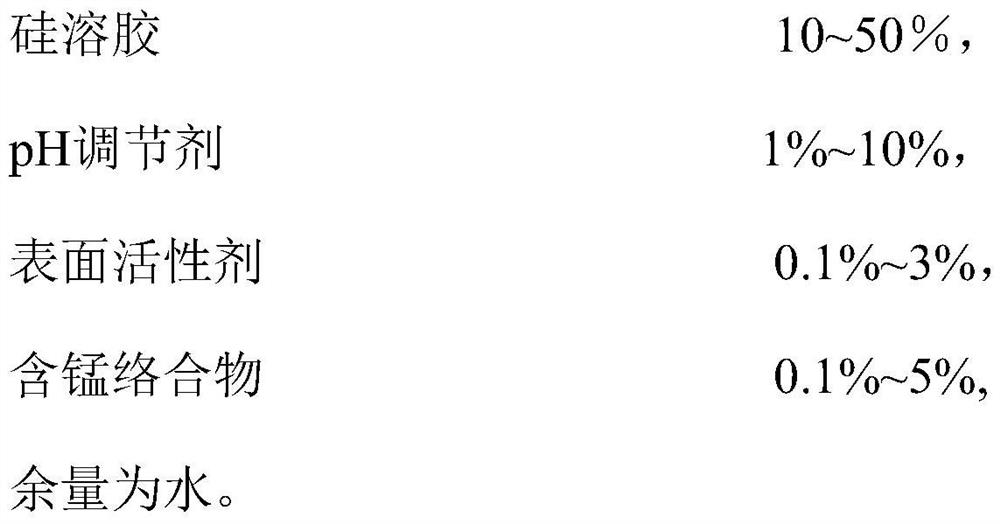

[0050] Sapphire chemical mechanical polishing fluid consists of the following components:

[0051] Silica sol 40wt%, particle size 80nm; hydroxyethylethylenediamine 3wt%; polyoxyethylene ether phosphate 2wt%; EDTA manganese complex 2wt%; the balance is deionized water. Test the removal rate, roughness, upper solid content and lower solid content of the polishing liquid of this embodiment according to the polishing conditions and methods of the previous embodiment to evaluate the polishing efficiency of the polishing liquid; Test the corresponding aforementioned parameters to evaluate the stability of the polishing liquid.

Embodiment 2

[0053] Sapphire chemical mechanical polishing fluid consists of the following components:

[0054] Silica sol 35wt%, particle size 100nm; ethylenediamine 5wt%; polyoxyethylene sodium sulfate 0.5wt%; manganese citrate complex 0.3wt%; the balance is deionized water. Test the removal rate, roughness, upper solid content and lower solid content of the polishing liquid of this embodiment according to the polishing conditions and methods of the previous embodiment to evaluate the polishing efficiency of the polishing liquid; Test the corresponding aforementioned parameters to evaluate the stability of the polishing liquid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com