Synthesis method of trifluoroethoxy vinyl phosphate

A technology of vinyl trifluoroethoxy phosphate and synthesis method, which is applied in chemical instruments and methods, compounds of Group 5/15 elements of the periodic table, organic chemistry, etc., which can solve the problems of poor purity, lower reaction efficiency, and influence on reaction Yield and other issues, to achieve the effect of reducing the violent occurrence of side reactions, mild reaction process, and simple reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

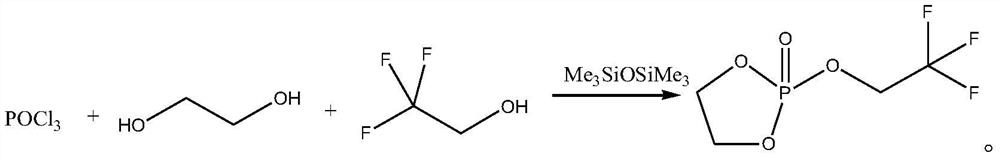

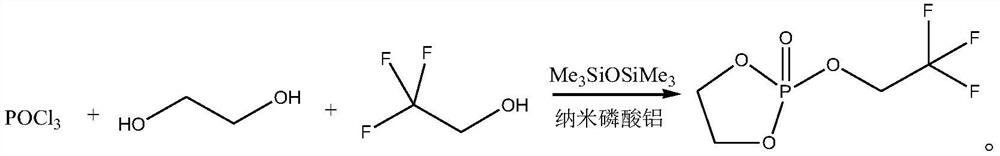

[0021] The synthetic method of trifluoroethoxy vinyl phosphate, its synthetic steps are as follows:

[0022] Disperse 0.3 g of nano-aluminum phosphate in 20 mL of dichloromethane to obtain a nano-aluminum phosphate dispersion;

[0023] Take 15.33g (0.1mol) of phosphorus oxychloride and 17.05g (0.105mol) of hexamethyldisiloxane, stir and mix them and carry out pre-reaction at 30°C for 1h, then add nano-aluminum phosphate dispersion at 30°C, and then maintain for 30 Slowly add 6.83g (0.11mol) ethylene glycol and 11g (0.11mol) trifluoroethanol dropwise at °C, slowly raise the temperature to 80°C, maintain 80°C for esterification reaction for 6h, filter, concentrate under reduced pressure to remove volatile solvents, and pass Vigreux Fractional distillation in the fractionating column yielded 19.01g trifluoroethoxy vinyl phosphate (also known as 2-trifluoroethoxy-2-oxo-1,3,2-dioxaphospholane), yield 92.25% , with a purity of 99.7%, the specific chemical reaction formula is as fol...

Embodiment 2

[0026] The synthetic method of trifluoroethoxy vinyl phosphate, its synthetic steps are as follows

[0027] Disperse 0.46g of nano-aluminum phosphate in 20mL of dichloromethane to obtain a nano-aluminum phosphate dispersion;

[0028] Take 15.33g (0.1mol) of phosphorus oxychloride and 17.86g (0.11mol) of hexamethyldisiloxane, stir and mix them and carry out pre-reaction at 25°C for 1.2h, then add nano-aluminum phosphate dispersion at 25°C, and then maintain Slowly add 7.14g (0.115mol) ethylene glycol and 11.5g (0.115mol) trifluoroethanol dropwise at 25°C, slowly raise the temperature to 85°C, maintain 85°C for esterification for 5 hours, filter, concentrate under reduced pressure to remove volatile solvents, and then Vigreux fractionation column fractionation, namely get 18.97g trifluoroethoxy vinyl phosphate (also known as 2-trifluoroethoxy-2-oxo-1,3,2-dioxaphospholane), yield 92.06%, purity 99.5%.

Embodiment 3

[0030] The synthetic method of trifluoroethoxy vinyl phosphate, its synthetic steps are as follows:

[0031] Disperse 0.15 g of nano-aluminum phosphate in 15 mL of dichloromethane to obtain a nano-aluminum phosphate dispersion;

[0032] Take 15.33g (0.1mol) of phosphorus oxychloride and 17.54g (0.108mol) of hexamethyldisiloxane and stir and mix them at 20°C for 1.4h, then add nano-aluminum phosphate dispersion at 20°C, and then maintain Slowly add 7.01g (0.113mol) ethylene glycol and 12g (0.12mol) trifluoroethanol dropwise at 20°C, slowly raise the temperature to 83°C, maintain 83°C for esterification reaction for 4h, filter, concentrate under reduced pressure to remove volatile solvents, and then Vigreux fractionation column fractionation, obtains 19.12g trifluoroethoxy vinyl phosphate (also known as 2-trifluoroethoxy-2-oxo-1,3,2-dioxaphospholane), yield 92.79 %, purity 99.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com