Ionic liquid doped water-soluble polythiophene composite film as well as preparation method and application thereof

A water-soluble polythiophene, ionic liquid technology, applied in electrolytic organic material plating, coating and other directions, can solve the problems of PEDOT film solubility and electrochromic performance to be improved, hindering electronic transition, reducing electrochromic performance and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The invention provides a method for preparing a water-soluble polythiophene composite film doped with an ionic liquid, comprising the following steps;

[0029] mixing sodium polystyrene sulfonate, 3,4 ethylenedioxythiophene, lithium perchlorate, sodium dodecylbenzene sulfonate and water to obtain an anionic water deposition solution;

[0030] mixing the ionic liquid with the anionic water deposition solution to obtain a deposition solution;

[0031] The deposition solution is used for electrochemical deposition to obtain the ionic liquid-doped water-soluble polythiophene composite film.

[0032] The invention mixes sodium polystyrene sulfonate, 3,4 ethylenedioxythiophene, lithium perchlorate, sodium dodecylbenzene sulfonate and water to obtain anion water deposition solution.

[0033] In the present invention, the mass ratio of the 3,4 ethylenedioxythiophene to lithium perchlorate is preferably 8.925:0.3197-0.638, more preferably 8.925:0.523.

[0034] In the present i...

Embodiment 1

[0050] A preparation method of a water-soluble polythiophene composite film doped with ionic liquid, comprising the steps of:

[0051] Use an electronic balance to weigh 0.3197g of LiClO 4 , prepared into 30 mL of LiClO 4 Aqueous solution, ultrasonically mixed, weighed 8.925g EDOT and 4.5g SDBS were slowly added dropwise, ultrasonic 30min. Use a graduated cylinder to measure 30 mL of the PSS solution and add it to the above solution to obtain a water deposition solution containing a large number of uniformly dispersed anions.

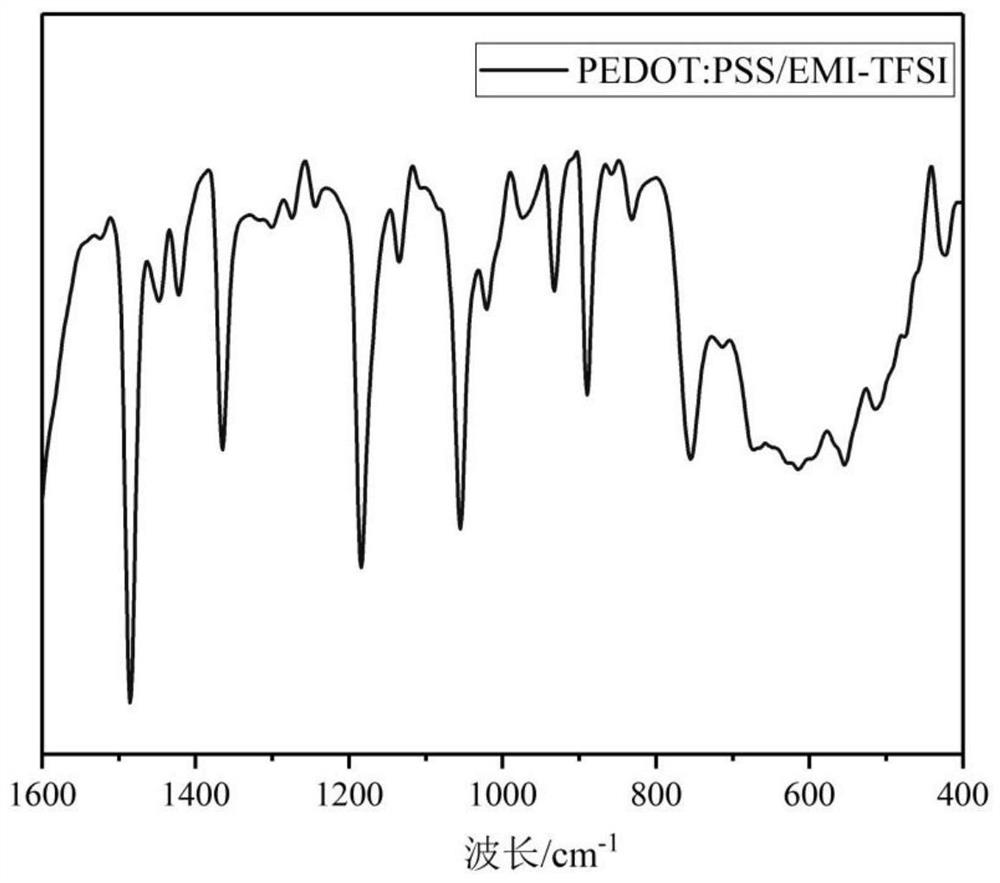

[0052] Weigh 5g of the ionic liquid EMI-TFSI and mix it into the above solution, and mix uniformly by ultrasonic to obtain the deposition solution.

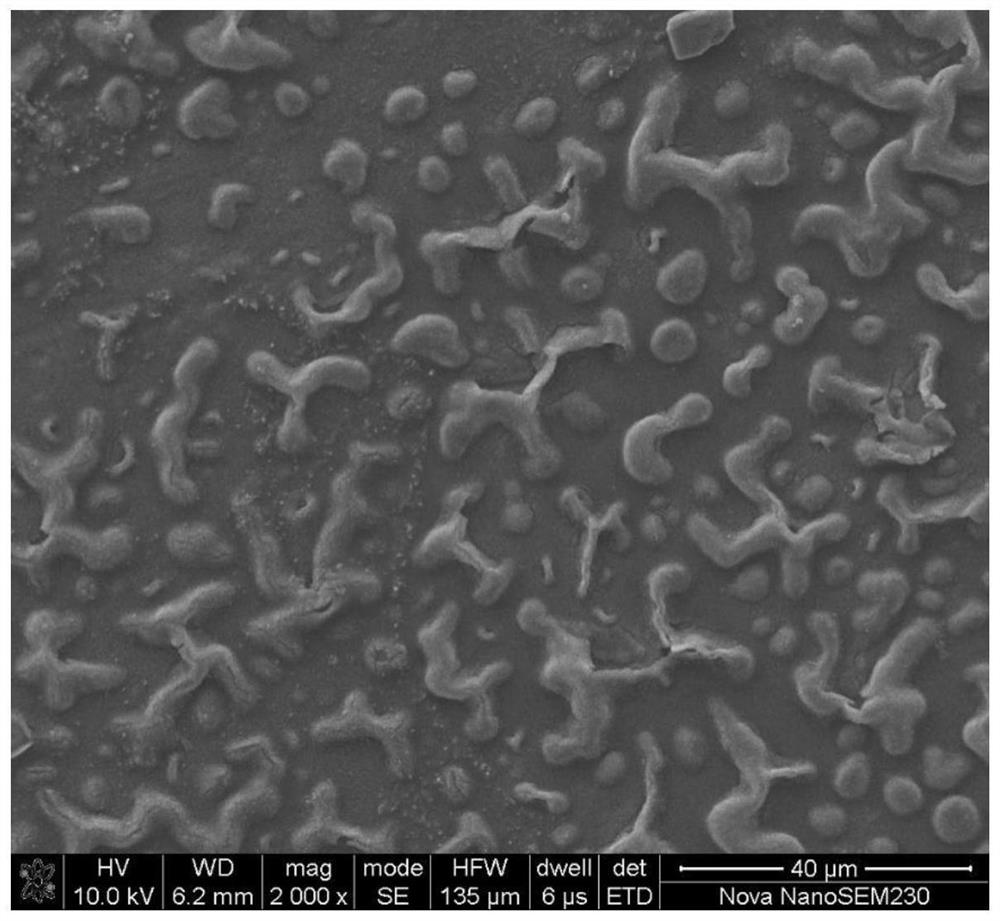

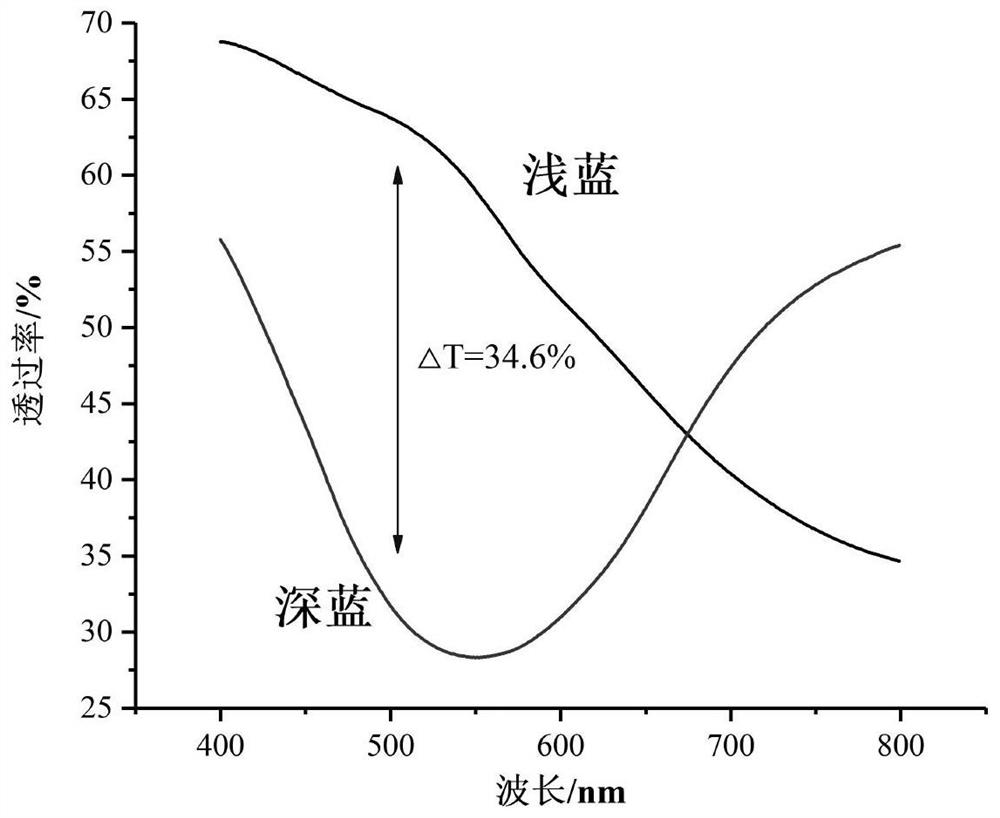

[0053] The obtained deposition solution is poured into the electrolytic cell, and the in-situ electrochemical polymerization is carried out by using the Auto-lab electrochemical workstation combined with the three-electrode system. Among them, 9mm×50mm indium tin oxide (ITO) conductive glass is used as W...

Embodiment 2

[0059] A preparation method of a water-soluble polythiophene composite film doped with ionic liquid, comprising the steps of:

[0060] Weigh 0.523g of LiClO using an electronic balance 4 , prepared in 40 mL of LiClO 4 Aqueous solution, ultrasonically mixed, weighed 8.925g EDOT and 6g SDBS were slowly added dropwise, ultrasonic 30min. Use a graduated cylinder to measure 40 mL of the PSS solution and add it to the above solution to obtain a water deposition solution containing a large number of uniformly dispersed anions.

[0061] Weighed 6 g of ionic liquid 1-ethyl-3-methylimidazolium perchlorate (HOEtMIm-Cl) and mixed it into the above solution, and mixed it uniformly by ultrasonic to obtain a deposition solution.

[0062] The obtained deposition solution is poured into the electrolytic cell, and the in-situ electrochemical polymerization is carried out by using the Auto-lab electrochemical workstation combined with the three-electrode system. Among them, 9mm×50mm indium tin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com