Preparation method and application of anti-ultraviolet dendritic silicon dioxide nanomaterial

A technology of silica and nanomaterials, applied in the field of plastic additives and anti-aging of plastics, can solve the problems of inorganic ultraviolet shielding agents easy to agglomerate, accelerate polymer degradation, affect the light transmittance of substrates, etc., to improve anti-UV aging. Effect, low concentration of use, beneficial to environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

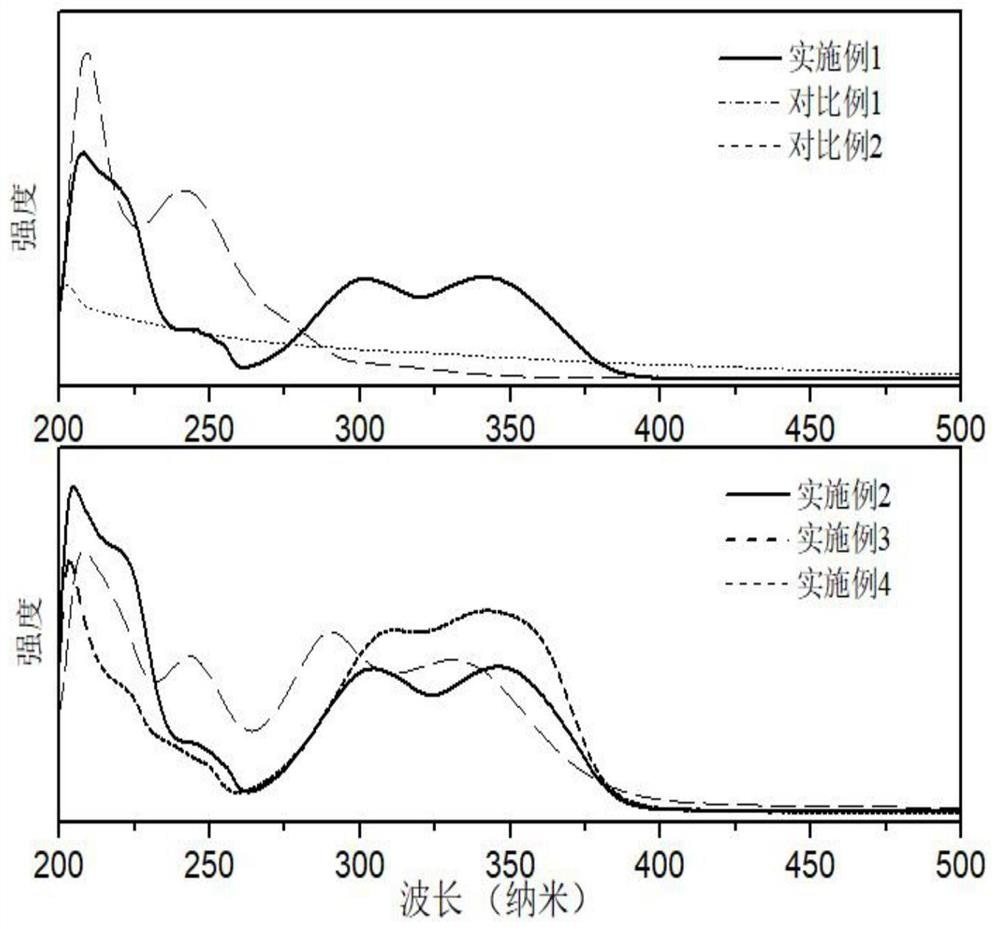

[0024] 12g tetraethyl orthosilicate, 1g γ-aminopropyltriethoxysilane, 1.0g 3-[3-(2-H-benzotriazol-2-yl)-4-hydroxy-5-tert-butyl Base phenyl]-propionic acid-polyethylene glycol 300 ester and 0.8g cetyltrimethylammonium bromide are dissolved in the mixed solvent of 250mL ethanol / water volume ratio 4:1, use ammonia water to adjust pH to 9, Stir and react at 25°C for 3 hours; wash the resulting reaction product with absolute ethanol, filter, and freeze-dry to obtain the anti-ultraviolet dendritic silica nanomaterial SiO 2 -1, its TEM image is shown in figure 1 , the nitrogen adsorption-desorption curve is shown in figure 2 , the ultraviolet-infrared absorption spectrum of the ethanol dispersion solution of anti-ultraviolet dendritic silica nanomaterials is shown in image 3 . figure 1 It can be seen that SiO 2 -1 is a sphere with a diameter of 250 nm, and has a dendritic structure extending from the center to the surroundings.

Embodiment 2

[0032] 13g tetraethyl orthosilicate, 2.0g 3-[3-(2-H-benzotriazol-2-yl)-4-hydroxy-5-tert-butylphenyl]-propionic acid-polyethylene Alcohol 300 ester and 0.8g of cetyltrimethylammonium bromide were dissolved in 250mL of ethanol / water (volume ratio 4:1) solvent, and the pH was adjusted to 10 with ammonia water, and the reaction was stirred at 40°C for 10 hours; The resulting reaction product is washed with absolute ethanol, filtered, and freeze-dried to obtain the anti-ultraviolet dendritic silica optical nanomaterial SiO 2 -2.

[0033] The main difference between Example 2 and Example 1 is that a single silicon source is used and the content of UV absorber is increased. In 2 hours, the reaction product was less, and the reaction temperature and the reaction time were prolonged to produce a sufficient amount of white product.

Embodiment 3

[0035] Mix 12g tetraethyl orthosilicate, 1g γ-aminopropyltriethoxysilane, 1.5g 4-(4,6-diphenyl-S-triazine)-1,3-resorcinol with 0.8g Hexadecyltrimethylammonium bromide is dissolved in the solvent of 250mL ethanol / water (volume ratio 4:1), uses ammonia water to adjust pH to 9, stirs reaction at 25 ℃ for 2 hours; Washing, filtering, and freeze-drying to obtain the anti-ultraviolet dendritic silica nanomaterial SiO 2 -3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com