Manufacturing method of woven composite material pipe fitting with variable stiffness characteristic

A composite material tube and composite material technology, applied in the application field of braided composite materials, can solve the problem of not many designs, and achieve the effects of good structural integrity, simple operation and strong structural designability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

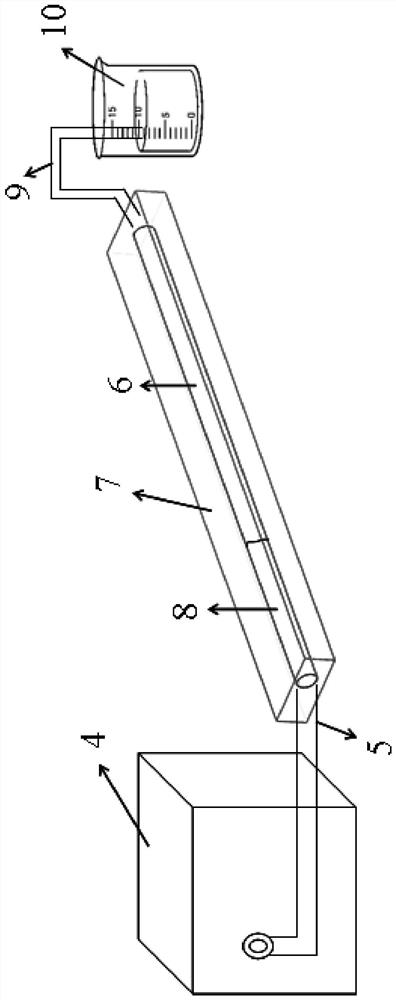

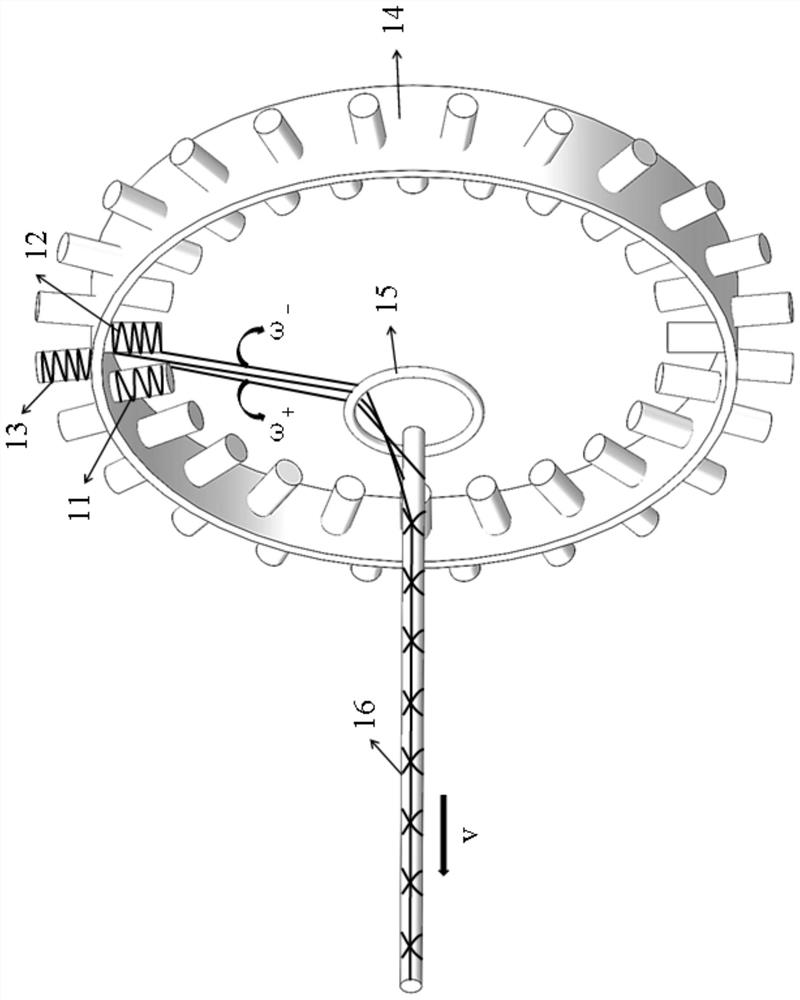

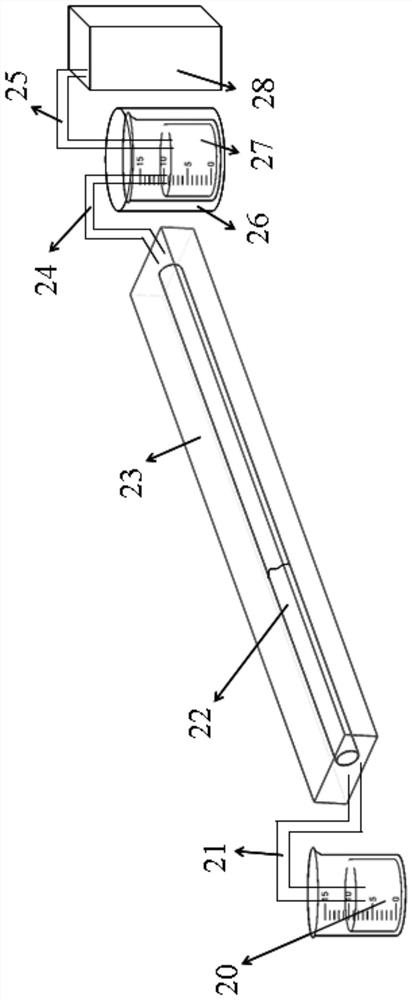

[0041] Please refer to the attached figure 1 to attach Figure 5 As shown, the present invention is a method for manufacturing braided composite pipe fittings with variable stiffness characteristics. The equipment required for this method includes a wax casting machine 4, a wax casting mold 7, a metal pipe 6, an annular braiding machine 14, a manipulator, and a punching machine. device, vacuum tank 26, vacuum pump 28, balance, oven; the materials used include wax 8, carbon fiber bundles, epoxy resin, curing agent, vacuum bag 23, diversion net 19, release cloth 18, conduits 5, 9, 21, 24, 25, beaker I10, beaker II 20, beaker III27.

[0042] The manufacturing method of the braided composite material pipe fitting with variable stiffness features of the present invention is divided into two stages, one is the weaving stage, and the other is the curing stage.

[0043] Wherein, the weaving stage includes the following process steps:

[0044] 1-1), prepare the mandrel 16: put the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com