Thiamine nitrate sustained-release microcapsule and preparation method thereof

A technology of slow-release microcapsules and thiamine nitrate, which is applied in the direction of microcapsules, capsule delivery, and pharmaceutical formulations. uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

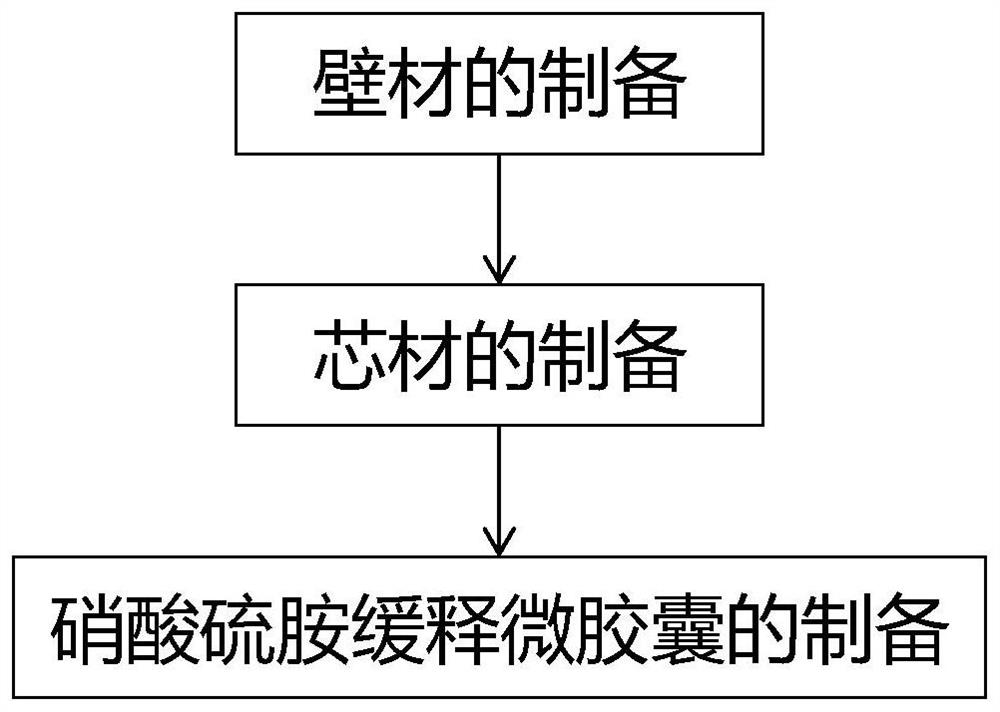

[0030] The preparation method of described thiamine nitrate slow-release microcapsules, comprises the steps:

[0031] S1. Preparation of wall material: Wash the coconut shell, crush and sieve it, then place it in a vacuum environment for carbonization to obtain coconut shell carbon ash, then dissolve the coconut shell carbon ash in water to obtain coconut shell carbon Gray aqueous solution, then add plant hydrolytic enzyme powder to described coconut shell carbon ash aqueous solution to carry out enzymolysis reaction, the addition amount of described plant hydrolytic enzyme powder is 0.05% (W / V), the temperature of described enzymolysis reaction is 25 ℃ , the time is 1h, the modified coconut shell solution is obtained, and finally polyethyleneimine is added to the above-mentioned modified coconut shell solution to obtain a wall material mixture, the modified coconut shell and polyethylene imine in the wall material mixture The mass ratio of amine is 1:1;

[0032] S2. Preparat...

Embodiment 2

[0035] The preparation method of described thiamine nitrate slow-release microcapsules, comprises the steps:

[0036]S1. Preparation of wall material: Wash the coconut shell, crush and sieve it, then place it in a vacuum environment for carbonization to obtain coconut shell carbon ash, then dissolve the coconut shell carbon ash in water to obtain coconut shell carbon Gray aqueous solution, then add plant hydrolytic enzyme powder to described coconut shell carbon ash aqueous solution to carry out enzymolysis reaction, the addition amount of described plant hydrolytic enzyme powder is 0.08% (W / V), the temperature of described enzymolysis reaction is 35 ℃ , the time is 1.5h, and the modified coconut shell solution is prepared, and finally polyethyleneimine is added to the above-mentioned modified coconut shell solution to obtain a wall material mixture, and the modified coconut shell and polyethylene in the wall material mixture are The mass ratio of imine is 3:1;

[0037] S2. P...

Embodiment 3

[0040] The preparation method of described thiamine nitrate slow-release microcapsules, comprises the steps:

[0041] S1. Preparation of wall material: Wash the coconut shell, crush and sieve it, then place it in a vacuum environment for carbonization to obtain coconut shell carbon ash, then dissolve the coconut shell carbon ash in water to obtain coconut shell carbon Gray aqueous solution, then add plant hydrolytic enzyme powder to described coconut shell carbon ash aqueous solution to carry out enzymolysis reaction, the addition amount of described plant hydrolytic enzyme powder is 0.1% (W / V), the temperature of described enzymolysis reaction is 40 ℃ , the time is 2h, and the modified coconut shell solution is prepared, and finally polyethyleneimine is added to the above-mentioned modified coconut shell solution to obtain a wall material mixture, and the modified coconut shell and polyethyleneimine in the wall material mixture are The mass ratio of amine is 5:1;

[0042] S2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com